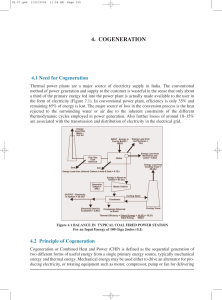

TURBINE INSTALLATIONS OF NUCLEAR POWER PLANTS INTRODUCTION. CYCLES Zenkov Andrey Viktorovich CONTACT INFORMATION Zenkov Andrey Viktorovich avz41@tpu.ru Building 4, room 112 2 FEATURES OF STEAM TURBINES 3 FEATURES OF STEAM TURBINES 4 FEATURES OF STEAM TURBINES 5 STEAM TURBINE OPERATION https://www.youtube.com/watch?v=SPg7hOxFItI 6 CONCEPTUAL DIAGRAM OF A POWER PLANT The steam turbine is used as a prime mover in power plants for power utilities and industrial users, or as a large-scale mechanical driver for various industrial uses The following cycles are mainly adopted for the standard cycle of the actual steam prime mover: 1. Rankine cycle; 2. Regenerative cycle; 3. Reheat cycle; 4. Reheat regenerative cycle. 7 RANKINE CYCLE Rankine cycle is the most basic system for a steam prime mover in actual plants. 8 RANKINE CYCLE The following sequence shows the condition of the fluid at each point: 1: Superheated steam at the boiler super-heater outlet (steam turbine inlet). 1-2: Adiabatic expansion in the steam turbine (ideal condition) from turbine inlet to turbine outlet (the condenser inlet). 2: Wet steam at the steam turbine outlet (the condenser inlet). 2-3: Condensing process in the condenser. 3: The condenser outlet (the boiler feed pump inlet). 3-4: Adiabatic pressure rising process to the boiler pressure in the boiler feedwater pump. 4: Compressed water at the boiler feed pump outlet (the boiler inlet). 4-5: Heating process under constant pressure to saturate conditions in the boiler. 5: Point at saturated condition of water in the boiler. 5-6: Evaporating process under constant pressure in the boiler evaporator. 6: Saturated steam at the boiler evaporator outlet (the super heater inlet). 6-1: Heating process under constant pressure in the boiler super heater. 9 THERMAL EFFICIENCY Theoretical thermal efficiency of the Rankine cycle: Internal thermal efficiency of the steam turbine: 10 REHEAT CYCLE steam is reheated after the high-pressure turbine; higher thermal efficiency (by 4-5%); lower moisture content in low-pressure turbine. 11 REGENERATIVE CYCLE reduce this heat loss by means of extracting steam to the feedwater heater from the intermediate stages of the steam turbine; thermal efficiency improvement; equipment costs increase. 12 BWR CYCLE generates steam from water in the reactor itself, and uses the steam directly to drive the steam turbine; lower pressure conditions than PWR; the steam used in the turbines includes the radioactive materials; the radiation shields for the components, measures towards leakage prevention of the radioactive steam from the turbines, the decontamination of the components at their maintenance 13 PWR CYCLE two coolant systems; the secondary coolant system is separated from the primary coolant system; steam turbines do not require the radiation protection measures in their operation and maintenance. 14 PWR CYCLE 15 TYPES OF STEAM TURBINES condensing turbines; back pressure turbines; extraction back pressure turbines; extraction condensing turbines; mixed-pressure turbines. 16 CONDENSING TURBINE is able to use the total energy of the inlet steam flow to a maximum extent; is used for power utilities that want to supply electricity to consumers as much as possible; has a lot of heat discharge loss; consists of many turbine stages and has large steam flow in the LP turbine; requires a larger condenser. 17 EXTRACTION TURBINE is able to change the electric power and the process steam flow independently by adjusting inlet steam flow and process steam flow. 18 BASIC EQUATIONS Basic equations of one-dimensional flow of compressible fluid essential for describing the process of power conversion in a turbine stage and its calculation: p k const 1. equation of state 2. equation of continuity 3. momentum equation 4. energy equation (energy conservation) G0 F0 c0 0 G1 F1c1 1 h0 c02 / 2 q h1 c12 / 2 l. 19