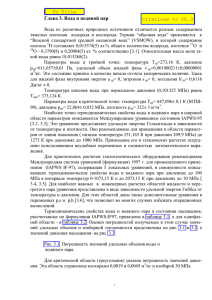

ISSN 00406015, Thermal Engineering, 2015, Vol. 62, No. 5, pp. 322–328. © Pleiades Publishing, Inc., 2015. Original Russian Text © V.F. Kasilov, A.A. Dudolin, I.V. Gospodchenkov, 2015, published in Teploenergetika. STEAMTURBINE, GASTURBINE, AND COMBINEDCYCLE PLANTS AND THEIR AUXILIARY EQUIPMENT The Effectiveness of Using the CombinedCycle Technology in a Nuclear Power Plant Unit Equipped with an SVBR100 Reactor V. F. Kasilov, A. A. Dudolin, and I. V. Gospodchenkov Moscow Power Engineering Institute National Research University, Krasnokazarmennaya ul. 14, Moscow, 111250 Russia email: kasilovvf@mpei.ru Abstract—The design of a modular SVBR100 reactor with a leadbismuth alloy liquidmetal coolant is described. The basic thermal circuit of a power unit built around the SVBR100 reactor is presented together with the results of its calculation. The gross electrical efficiency of the turbine unit driven by saturated steam at gr a pressure of 6.7 MPa is estimated at ηel = 35.5%. Ways for improving the efficiency of this power unit and increasing its power output by applying gasturbine and combinedcycle technologies are considered. With implementing a combinedcycle powergenerating system comprising two GE6101FA gasturbine units with a total capacity of 140 MW, it becomes possible to obtain the efficiency of the combinedcycle plant equipped with gr the SVBR100 reactor ηel = 45.39% and its electrical power output equal to 328 MW. The heatrecovery boiler used as part of this power installation generates superheated steam with a temperature of 560°C, due to which there is no need to use a moisture separator/steam reheater in the turbine unit thermal circuit. Keywords: nuclear power plant unit, SVBR100 nuclear reactor, gasturbine unit, combinedcycle power plant, steam turbine, turbine unit thermal circuit, power unit efficiency and capacity DOI: 10.1134/S0040601515050043 Works are presently underway in structural units of the Rosatom State Atomic Energy Corporation on developing an experimental industrial NPP power unit equipped with an SVBR100 nuclear reactor (the Dimitrovgrad town in the Ul’anovsk oblast) with ther mal capacity Qr = 280 MW and a steamturbine unit with electrical capacity Nel = 100 MW. The SVBR100 modular fastneutron reactor [1, 2] has been designed to operate in a closed fuel cycle with an eutectic lead– bismuth alloy serving as a liquid metal coolant. This technology has been elaborated during operation of similar reactors at Russian nuclear submarines, and the project of the SVBR100 reactor meets to a con siderable degree the requirements posed on modern nuclear power installations, specifically, the safety requirements, the requirements for the reactor plant service life (from 40 to 60 years), and for achieving the level of specific capital outlays for constructing a nuclear power unit commensurable with those for thermal power plants $(1000–1700)/kW. Small capacity power units may be attractive for projects with a limited amount of investments, and owing to a high safety level, NPPs equipped with SVBR100 reactors can be constructed in close vicinity of residential areas. Owing to these features, such power units can be used for district heating purposes in cities [3, 4]. According to assessments made by the International Atomic Energy Agency (IAEA), the demand for small and mediumcapacity reactors (100–400 MW) around the world to the year 2040 will make from 500 to 1000 units, and the total cost of this market will make $(300–600) billion. Russia, the United States, France, and China occupy the leading positions in research and development works on these reactors. It should be noted that SVBR100 reactors may account for 10–15% in the new segment of the nuclear power industry market. An important feature of the SVBR100 reactor plant is that its primary coolant circuit has an integral layout; the equipment of this circuit is placed in the strong casing of the reactor monounit (RMU), and the hydraulic links are formed without using pipelines and valves (Fig. 1). The RMU central part contains an assembly com prising the core and the reactor control and protection system’s (CPS) control rods. The core is surrounded by an invessel radiation shield, which accommodates evaporator modules and reactor coolant pumps (RCPs). The RMU heat removal loops operate with natural circulation of coolants the intensity of which is sufficient for passively cooling down the reactor with out dangerous overheating of its core. A protective plug is mounted above the core, on the head of which the drives of CPS absorber rods are mounted. Owing to its compact overall dimensions (4.53 m in diameter and 7.55 m in height), the reactor monounit can be transported in completely prefabricated state (also by railway), due to which NPPs equipped with such reac tors can be constructed within a shorter period of time 322 THE EFFECTIVENESS OF USING THE COMBINEDCYCLE TECHNOLOGY and at a lower cost. The time interval between the reactor refueling operations is 7–8 years. The adopted circulation arrangement with free levels of coolant in the RMU upper part and in the channels of steam gen erator modules taken in combination with a low cool ant flow velocity in the path downtake parts ensure reliable separation of steam–water mixture from the coolant if loss of tightness occurs in the evaporator module tube system. The secondary coolant circuit operates according to the scheme with multiple forced circulation of steam–water working medium. Owing to the reactor, steam generator modules, reactor coolant pumps, and other equipment being placed in a common casing that does not contain any pipelines or valves, a high level of reactor plant safety is ensured. For example, the possibility of the follow ing emergency situations is excluded: instantaneous neutron reactor power excursion, loss of coolant from the reactor, and propagation of radioactivity from the reactor coolant system on a scale at which the popula tion living outside of the NPP boundaries have to be evacuated. The safety systems used as part of the reac tor plant come in action in a passive manner and do not contain elements failures of which may be con nected with the influence of a human factor. The reac tor plant safety does not depend on the state of steam turbine unit systems and equipment, which is designed and manufactured according to the generalindustry codes and regulations. This article presents the version of an SVBR100 reactorbased condensing power unit’s thermal circuit without steam superheating modules comprising a K1006.7 twocylinder turbine (Fig. 2) that has been prepared by the authors of this article and calculated using the Thermoflow software system. The turbine highpressure cylinder’s (HPC) flow path is fitted with a throttle steam admission system and a looptype steam expansion arrangement. The twoflow lowpressure cylinder (LPC) used in the considered version has laststage rotor blades with length l2 = 665 mm. In case of using 960mm or longer rotor blades it is possible to implement a singleflow steam expansion arrangement in the LPC. The tur bine unit regenerative system consists of two high pressure heaters, a deaerator operating at pressure pd = 0.86 MPa, three lowpressure heaters, the main ejector, and a gland steam ejector. The steam flow rate from the reactor’s steam generator at the feed water temperature tf.w = 226°C is equal to 160.86 kg/s. The saturated steam pressure upstream of the turbine HPC is р0 = 6.7 MPa. Such a turbine unit version with a rea sonable level of vacuum in the condenser (in the pre sented calculation version, pc = 6 kPa) can be imple mented only with subjecting steam to moisture separa tion and reheating. In this connection, a moisture separator/steam reheater (MSR) with the split pres sure pspl = 0.99 MPa is installed downstream of the steam turbine HPC. The MSR steam reheating part’s THERMAL ENGINEERING Vol. 62 No. 5 2015 323 6 5 4 3 2 1 Fig. 1. Longitudinal section of the SVBR100 reactor monounit. (1) Reactor core, (2) RMU casing, (3) protective plug, (4) evaporator modules, (5) CPS drives, and (6) RCP. first stage receives steam from the turbine HPC extrac tion, and its second stage receives live steam from the turbine unit main steam line (see Fig. 2). The presented power unit has electric capacity gr N el = 101.33 MW, the turbine unit electrical efficiency is ηelgr = 35.5%, the heat rate is q elgr = 9947 kJ/(kW h), and the specific nuclear fuel rate is bn.f = 158 g/MW. Unfortunately, like for the technologies of water cooled watermoderated powergenerating reactors (VVER), owing to the fact that the live steam temper ature in the steamturbine unit equipped with an SVBR100 reactor is limited at the level corresponding to saturation state (t0 = 282.8°C), the maximum achievable gross efficiency cannot be higher than 37%. The relatively low level of efficiency and the problems that arise during wet steam expansion in the turbine flow path prompt the designers to find solutions that would make it possible to achieve better performance efficiency of the steam turbine unit and higher reliabil ity of the nuclear power unit at the existing stateof theart in power engineering. Application of gastur 1037.96 THERMAL ENGINEERING HPH5 2776.5 1.895 764.1 22.5 180.1 11.8 217.2 HPH4 9.7 0.86 734.3 D 149.1 173.4 FWP 211.1 1.952 2689.8 HIPC 3.497 931.1 149.1 207.97 7.58 890.6 18.3 245 3.654 2768.1 6.7 154.75 282.8 SR1 103 6.54 112.5 107.65 1.016 452.1 0.426 472.2 LPH3 S 3.619 1059 111.7 6 77.35 SR2 6.11 286.3 0.1445 323.91 96.9 72.35 1.171 303.8 LPH2 6 0.1516 2693.7 68.67 244.5 0.9885 2610.3 270 88.7 37.25 1.326 157.2 LPH1 5.56 75.74 0.0398 2635.9 101 0.95 2989.7 EC CP C 87.6 36.7 0.006 2556.7 98.9 MW p, MPa h, kJ/kg G, kg/s t, °C LPC Fig. 2. Thermal process circuit of the power unit built around the SVBR100 reactor. R is the reactor; HIPC is the steam turbine’s combined high and intermediatepressure cylinder; S is the MSR separator section; SR1 and SR2 are the MSR’s steam reheating sections 1 and 2, respectively; LPC is the steam turbine’s lowpressure cylinder; C is the condenser; CP is the condensate pump; LPH1–LPH3 are the lowpressure heaters; D is the deaerator; FWP is the feed water pump; HPH4–HPH5 are the highpressure heaters; and EC are the ejector coolers. 149.1 223.4 7.5 160.86 226 R 2778.8 143.2 103 6.97 179.4 0.86 603.3 6.932 2777.9 6.11 285.2 7.0 160.86 287 7.74 244.5 6.932 1263.6 3.619 2702.8 6.54 192.8 0.4473 2843.3 324 KASILOV et al. Vol. 62 No. 5 2015 THE EFFECTIVENESS OF USING THE COMBINEDCYCLE TECHNOLOGY bine and combinedcycle technologies in NPP power units is the most significant solution [5–8]. In our opin ion, those who strive to achieve the efficiency of the abovementioned power units higher than 45% should pay keen attention to the possibility of using combined cycle technologies in nuclear power engineering. The most accessible and simple approach to solv ing the problems concerned with maneuverability, covering the peak loads of electricity consumers, and supplying heat to them is to use gas turbine units (GTUs). Since GTUs feature high load pickup rate capabilities and short startup time, they can serve as sources of reliable emergency and standby power sup ply to the auxiliaries of NPP power units. It is possible to consider application of an independent GTU with a heat exchanger instead of a boiler unit (the latter usu ally operates on fuel oil), which is designed at all NPPs for supporting the adjustment and commissioning works. The time taken to install a GTU is shorter as compared with that taken to construct an NPP power unit; therefore, it can generate electricity already in the course of constructing and installing the main equipment. The GTU can also be used as a peaking duty power unit for generating electricity and for replacing the means for preheating feed water in the NPP turbine unit regenerative system. We mean here the power unit maneuvering power generated both by the peakingduty GTU and by forcing the steam tur bine with fully or partially disconnecting the regener ative steam extractions. Different arrangements for replacing steam extractions to the MSR can also be considered. It should be pointed out that the GTU power performance characteristic allows its electric power output to be increased by 20–30% in the coldest periods of operation (the peaks of electric and heat loads in fall and winter). Since GTUs have the highest maneuverability indicators, their application is of much importance not only in covering peak loads, but also in extending the adjustment range of the NPP tur bine unit, and it is primarily connected with increasing the upper power output limit of the existing power unit. We cannot but point out the possibility of inde pendent GTU operation during scheduled and off scheduled outages of the nuclear reactor. The majority of the abovementioned GTU capaci ties are connected with using the “nuclear power unit + GTU” process circuits, which do not allow a consider able growth of power unit efficiency to be obtained, also due to a low extent of binarity in their thermodynamic cycles. As is well known, the highest efficiency in ther mal power engineering (50–60%) is obtained by using combinedcycle power plants (CCPs). The use of com binedcycle technology at NPPs opens the possibility to obtain steam with a temperature of higher than 500°C in the heatrecovery boiler, due to which there will be no need to use an expensive MSR, and the turbine can be designed for the superheated steam expansion condi tions. The use of such solutions will make it possible to achieve considerable improvement not only in the THERMAL ENGINEERING Vol. 62 No. 5 2015 325 power unit efficiency, but also in the reliability of its main equipment. It should also be borne in mind that the steam rate per unit of generated power in wetsteam turbines of NPPs is significantly higher than it is in the turbines of thermal power plants operating on super heated steam. For example, for superheating live steam supplied to a 1000 MW turbine unit to a temperature of 540°C, up to 35% of additional power capacity is required in the reactor evaporation modules, which corresponds to the required GTU capacity equal to around 1500 MW. The version involving the use of GTU of a smaller capacity, e.g., 300 MW, will make it possible to obtain live steam superheating by only 30– 40°C and achieve gross efficiency equal to around 39%. Below, the data reported in [5, 8] are given as exam ples of using different process circuits of combined cycle power units at NPPs. In [5], the effectiveness of using the GTE130850 gas turbine unit jointly with a VVER1000 reactor and a K10005.9 steam turbine was considered. Versions involving live steam super heating, reheating, and partial heating of feed water were calculated. It was shown that the system involving steam reheating in the CCP heatrecovery boiler is the most efficient one. In [8], the results obtained from cal culations of a CCP comprising the AP600 nuclear reac tor designed by Westinghouse (a 600MW lightwater reactor), a 1151.5 MW threecylinder steam turbine unit, and four V94.3A gas turbine units with the total capacity equal to 972.5 MW were presented. As a result, the capacity of such CCP totaled Nel = 2124 MW. Owing to the use of heat contained in the flue gases exhausted from the GTUs, the steam produced by the AP600 reactor’s steam generator is superheated in the steam superheating sections of four heatrecovery boil ers (HRBs) placed downstream of it is superheated to a level at which the live steam temperature upstream of the turbine is raised to t0 = 530°C. Feed water upstream of the steam generator is heated in the HRB econo mizer sections to a temperature of 226.9°C, and then saturated steam is generated in the reactor plant at a pressure of 5.72 MPa. One lowpressure heater, a deaerator, and a highpressure heater are used in the steam turbine unit thermal process circuit for heating feed water downstream of the condenser. It has been found from the calculation results that the use of com binedcycle technology results, apart from obtaining a significantly increased power output, the growth of power unit efficiency from 33.0% in the initial version to 49.4% in the CCP version. Clearly, the CCP process circuit presented above is difficult to implement, and primarily in case of using highcapacity reactor plants operating with large steam flow rates. However, for NPPs equipped with small and mediumcapacity reactors such solutions can well be implemented and will make it possible to obtain significant gains in efficiency, power capacity, and maneuverability. The authors of this article calcu lated a few versions of thermal process circuits for a CCP equipped with a SVBR100 reactor. One of these 326 KASILOV et al. GE 6101FA 70.2 MW 70.2 MW GTU no. 1 GE 6101FA GTU no. 2 7 3555 160.9 560 0.1018 629.4 412.5 594.4 HIPC LPC 187.6 MW HRB 0.006 2333.1 SSS 140.1 36.16 7.14 2770.7 C 160.9 287.2 SVBR100 CP 0.006 151.5 R D ES LPH 7.85 972.2 140.1 36.16 FWP 160.9 226 8.01 479.4 1.013 125.2 160.9 112.9 412.5 143.5 p, MPa h, kJ/kg G, kg/s t, °C Fig. 3. Thermal process circuit of the PGU330YaR combinedcycle power plant comprising the SVBR100 nuclear reactor. HRB is the heatrecovery boiler, SSS is the steam superheating section, and ES is the economizer section. The other notation is the same as in Fig. 2. versions with the feed water temperature upstream of the reactor plant tf.w = 226°C is shown in Fig. 3. This thermal circuit includes a lowpressure heater and a deaerator. Prior to be fed to the reactor plant, feed water is heated in the HRB economizer section. Mass flow rates (G, kg/s) and the thermodynamic parameters of working media (pressure р, MPa; temperature t, °C; and enthalpy h, kJ/kg) are indicated at the thermal cir cuit characteristic points. The process circuit does not show auxiliary pipeline mains, e.g., for steam from the turbine end seals and from the control valve stems. However, the relevant flow rates of steam and water were taken into account in calculating the circuit, which was modeled to a sufficient detail. The power unit output and the level of its electrical efficiency were estimated in the calculations. We consider the power unit configuration compris ing two GE 6101FA gas turbine units each having a capacity of 70 MW, which are supposed to be assembled and tested at the Russian Gas Turbines Company’s pro duction plant established within the framework of a joint enterprise of the General Electric Concern, the INTER RAO UES Company, and the Rostekh State Corporation, which is presently under construction. The total flow rate of gases with a temperature of 595°С supplied from the GTUs to the heatrecovery boiler is 412.5 kg/s. The heatrecovery boiler’s steam superheat ing section (see Fig. 3) is able to produce superheated steam with a temperature of 560°С at a pressure of 7.0 MPa (the live steam pressure upstream of the tur bine р0 = 6.7 MPa). The steam turbine set power output at the outdoor air temperature to.a = 15°C was found to be Nel = 187.6 MW (the steam turbine is marked as K1906.7). As a result, the total capacity of the CCP (marked as PGU330YaR) is Nel = 328.1 MW. At these operating parameters, the gross electrical efficiency was found to be ηelgr = 45.39%. The twocylinder steam tur bine consists of a combined high and intermediate pressure cylinder and a lowpressure cylinder with the 960mmlong laststage rotor blade. The steam expan sion process in the turbine flow path is shown in Fig. 4. The table presents the PGU330YaR power out put and efficiency values depending on the power out put ratio of GTU 1 and GTU 2. Here, we speak about the CCP indicators with the GTUs operating at partial loads up to the mode in which one of them (GTU 1) operates at 50% of its rated power output and the sec ond one (GTU 2) is shut down. Under such condi tions, the PGU330YaR total electric power output varies from 328.1 to 177.6 MW and its efficiency, from 45.39 to 35.5%. The results from calculations of the PGU330YaR carried out for different operating modes of the GE 6101FA gas turbine units depending on the out door air temperature are presented in Fig. 5. In the range of to.a from –30 to 30°C the power output varies by approximately 45 MW. THERMAL ENGINEERING Vol. 62 No. 5 2015 THE EFFECTIVENESS OF USING THE COMBINEDCYCLE TECHNOLOGY 327 NCCP, MW 380 560°С 360 340 287.2°С 320 x=1 p = 7 MPa 300 –30 –20 –10 –3.2 0 10 15 20 30 to.a, °С p = 1 MPa Fig. 5. Electric power output of the PGU330YaR com binedcycle plant as a function of outdoor air temperature. h, kJ/kg p = 152 kPa x = 0.903 p = 43 kPa p = 6 kPa S, kJ/(kg K) Fig. 4. Steam expansion process in the K1906.7 turbine flow path. The authors of this article carried out calculations of the CCP thermal circuit shown in Fig. 3 with the feed water temperature upstream of the SVBR100 reactor (after the HRB economizer section) tf.w = 240°C. To do so, we had to use GE 6111FA GTUs with a capacity of 72 MW [their efficiency is equal to 34.97% subject to fulfilling the requirements specified in GOST (State Standard) R 522002004)]. As a result, the CCP total capacity was Nel = 339.1 MW and its gross efficiency ηelgr = 46.23%. It should be pointed out that certain limitations are imposed on implementing CCPs and GTUs in the NPP process circuit in regard of fire safety, the regula tions for which will need the relevant correction. Lim itations may also be encountered in substantiating the economic efficiency of NPP power unit projects with the use of combinedcycle technology, for example, due to a high discounting rate adopted in the nuclear power industry, problems connected with determining the tariffs for electricity, and dispatch control con straints in operating the power units. At the same time, the authors of this article are sure that the necessary possibilities and scientific background for using com binedcycle technologies in nuclear power engineer ing are available in Russia already at present. In con trast to the Russian thermal power industry, in which we did not become the leaders in implementing com binedcycle technologies, the nuclear power industry of Russia can occupy the leading positions among the developed countries of the world community. CONCLUSIONS (1) The calculation results presented in this work have demonstrated that the use of combinedcycle technology in the power unit equipped with an SVBR100 nuclear reactor allows the electric power output of around 330 MW with efficiency at the level of 45% to be obtained. (2) In our opinion, the nuclear power industry of Russia can and should become one of leaders in implementing combinedcycle technologies in the process circuits of power units equipped with small and mediumcapacity nuclear reactors. The power output and efficiency values of the PGU330YaR power installation depending on the capacities of GE 6101FA gasturbine units at to.a = 15°C (subject to the conditions specified in GOST (State Standard) R 522002004) Shares of gas turbine units in generating the power output (NGTU1/NGTU2, %/%) Indicator Ratio of gas turbine unit power outputs NGTU1/NGTU2, MW/MW Ratio of gas turbine unit efficiencies ηGTU1/ηGTU2, %/% Steam turbine unit electric power output, NSTU, MW CCP power output NCCP, MW CCP efficiency ηCCP, % THERMAL ENGINEERING Vol. 62 100/100 100/75 100/50 100/0 75/0 50/0 70.2/70.2 70.2/52.7 70.2/35.1 70.2/0 52.7/0 35.1/0 34.16 30.43 25.96 34.16/34.16 34.16/30.43 34.16/25.96 No. 5 187.6 187.6 185.4 153.5 151.8 142.5 328.1 45.39 310.5 44.98 290.7 43.61 218.3 39.8 204.5 38.03 177.6 35.35 2015 328 KASILOV et al. REFERENCES 1. A. V. Zrodnikov, G. I. Toshinskii, and V. S. Stepanov, “Conversion of the technology of lead–bismuthcooled reactors: from the reactors for nuclearpowered subma rines to powergenerating reactors and ways of making nuclear power engineering on the basis of fastneutron reactors more attractive for investors,” in Proceeding of the International IAEA Conference “Fifty Years of Nuclear Power – the Next Fifty Years,” Obninsk, 2004. 2. A. V. Zrodnikov, G. I. Toshinskii, O. G. Grigor’ev, Yu. G. Dragunov, V. S. Stepanov, N. N. Klimov, I. I. Kopytov, V. N. Krushel’nitskii, and A. A. Gruda kov, “Modular multipurpose lead–bismuth fast reac tors for nuclear power engineering,” Therm. Eng. 52 (1), 17 (2005). 3. Yu. N. Kuznetsov, L. S. Khrilev, and V. P. Brailov, “The technical and economic principles and lines of develop ment of nuclear district heating cogeneration,” Therm. Eng. 55 (11), 926 (2008). 4. A. S. Kurskii and V. V. Kalygin, “The effectiveness of nuclear district heating cogeneration,” Energ. Polit., No. 4, 48–57 (2013). 5. S. V. Tsanev and S. N. Belozerov, “On the use of com binedcycle process circuits for steam turbine units operating on saturated steam,” Izv. Vyssh. Uchebn. Zaved., Energetika, No. 12, 70–74 (1988). 6. Z. Yu. Novikova, Achieving Better System Efficiency of PowerGenerating Complexes on the Basis of Nuclear Power Plants and Gas Turbine Units with Heat Storage, Candidate’s Dissertation in Technical Sciences (Sara tov Gos. Tekhn. Univ, Saratov, 2013). 7. Z. Yu. Novikova and V. A. Khrustalev, “The effectiveness of refusing from highpressure heaters in the NPPbased combinedcycle power plant’s process circuit,” Izv. Vyssh. Uchebn. Zaved., Probl. Energ., No. 9, 69–77 (2012). 8. M. A. Darwish, F. M. Al Awadhi, and A. O. Bin Amer, “Combining the nuclear power plant steam cycle with gas turbines,” Energy, No. 35, 4562–4571 (2010). Translated by V. Filatov THERMAL ENGINEERING Vol. 62 No. 5 2015