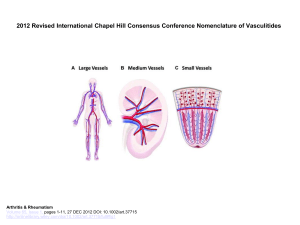

DOI 10.1007/s11148-024-00906-5 Refractories and Industrial Ceramics Vol. 64, No. 6, March, 2024 HOLLOW NANOSTRUCTURED Ni3Fe MICROSPHERES OBTAINED BY SPRAY PYROLYSIS B. B. Khaidarov,1 A. G. Yudin,1,4 D. S. Suvorov,1 D. V. Kuznetsov,1 D. V. Lysov,1 I. N. Burmistrov,2 and D. Yu. Karpenkov3 Translated from Novye Ogneupory, No. 12, pp. 32 – 37, December, 2023. Original article submitted November 16, 2023. A study of a two-stage method for the formation of nanostructured Ni3Fe is presented. Nanostructured Ni3Fe hollow microspheres were synthesized by ultrasonic spray pyrolysis (URP) from a mixture of aqueous solutions (10 wt.%) of nickel(II) and iron(III) nitrates. In the first stage, hollow microspheres with diameters in the range 0.5 – 10 mm were formed from a mixture of Ni and Fe oxides. The second stage involved metallization of a mixture of Ni and Fe oxides in a tube furnace in a hydrogen atmosphere. X-ray diffraction (XRD) data of the final product showed the presence of the Ni3Al phase and a crystallite size close to 40 nm. Scanning and transmission electron microscopy revealed the hollow morphology of the studied Ni3Fe microspheres. Their walls were assembled from crystallites with diameters of 30 – 60 nm. Keywords: spray-pyrolysis, hollow nanostructured microspheres, Ni3Fe. cles [23 – 27], and multicomponent systems [28 – 33]. The spray pyrolysis procedure includes several processes: 1 — spraying a starting salt solution [34 – 39]; 2 — solvent evaporation [40]; and 3 — product collection. The ability to use both inorganic and organic salts makes the USP method universal for producing multicomponent and well-mixed systems [41]. The USP method is well suited to producing materials with an ordered chemical composition. The simplicity of the technical equipment used for USP is one of the advantages of this method. The present research showed that hollow nanostructured Ni3Fe microspheres were formed by USP from nickel and iron nitrate precursors followed by heat treatment in an H2 atmosphere. INTRODUCTION Nanostructured materials are attracting heightened interest because of their specific physicochemical properties due to the transition from the bulk to the nanoscale state. Among them, magnetic nanoparticles have significant technological and theoretical interest. In particular, the compound Ni3Fe has found practical applications in electrical engineering, optics, and electronics. Its magnetically soft behavior demonstrates low coercive force and high magnetic permeability [1 – 3]. Ni3Fe and other magnetic composites based on Fe, Ni, Co, etc. are widely synthesized by mechanical milling in a planetary ball mill [1 – 3]. Crystalline and amorphous materials based on Ni–Fe are commonly molded by the Taylor(Ulitovsky technique [4 – 7] or the sol-gel method followed by metallization [8]. Foils based on Ni–Fe were formed by electrodeposition [9]. Ultrasonic spray pyrolysis (USP) is widely used to produce thin films [10 – 23], spherical hollow and dense parti- EXPERIMENTAL The starting precursors were Ni(NO3)2·6H2O (OOO Reakhim, AR grade), Fe(NO3)3·9H2O (OOO Reakhim, AR grade), and distilled H2O. The ratio of the salts was calculated to give an Ni:Fe stoichiometry of 3:1 in the final product. Figure 1 shows a conceptual diagram of the USP method [34, 42, 43]. A solution of the metal nitrates was sprayed using a DK 9-36 ultrasound generator at operating frequency 1 National University of Science and Technology MISiS, Moscow, Russia. 2 Plekhanov Russian University of Economics, Moscow, Russia. 3 Lomonosov Moscow State University, Moscow, Russia. 4 yudin@misis.ru 648 1083-4877/24/06406-0648 © 2024 Springer Science+Business Media, LLC Hollow Nanostructured Ni3Fe Microspheres Obtained by Spray Pyrolysis Fig. 1. Diagram of spray-pyrolysis system. 1.2 MHz. Aerosol drops were formed by annihilation of ultrasound cavitation bubbles and were transported by a carrier gas into a quartz reactor of length 500 mm and internal diameter 25 mm inside a Nabertherm 20/250/13 tube furnace. Air was used as the carrier gas. The carrier-gas flow rate was maintained by a KNF Neuberger D7911 pump at 16 L/min. The furnace temperature was held at ~1000°C. The obtained hollow microspheres were collected on a stainless-steel filter. The time of flight of the drops through the heated reactor was ~2 sec. Two parallel-sequential processes occurred in the furnace reactor. The first was solvent evaporation associated with transformation of the drops into particles. Evaporation of H2O and crystallization of the Ni and Fe nitrates began at the drop surface. The salt solution diffused from the bulk to the drop surface because of the concentration gradient and high temperature. The second process was thermal decomposition of the nitrate salts to form Ni and Fe oxides, NO2, and O2 according to the equations: 2Ni(NO3)2 ® 2NiO + 4NO2 + O2; 4Fe(NO3)2 ® 2FeO3 + 12NO2 + 3O2. The obtained samples were metallized in a Carbolite HZS 12/600E tube furnace in an H2 atmosphere at 450°C. 649 The metallization temperature was selected based on results of thermogravimetric studies. The morphology of the obtained samples was studied using a Tescan Vega 3 scanning electron microscope (Czechia) and a JEM 1400 transmission electron microscope (JEOL, Japan). The phase composition of the obtained samples was studied by x-ray phase analysis (XPA) on a Difray 401 instrument (NPK Nauchpribor, Russia) using Cr Ka-radiation (2.2909 Å). The specific surface area was studied by low-temperature N2 adsorption according to BET on a Quantachrome Nova 1200 e instrument (USA). The magnetic properties of the samples were studied using a Lake Shore VSM 7410 vibrating magnetometer (USA). Samples of hollow Ni3Fe microspheres were cold pressed beforehand at a load of 4 t/cm2. The thermogravimetric parameters were studied on a Thermal Advances SDT Q 600 instrument in the range 25 – 1000°C in air and H2 at heating rate 20°C/min. The size distribution of the microspheres was studied using a Zetasizer Nano ZS Z 3600 laser diffraction analyzer (Malvern, Great Britain). RESULTS AND DISCUSSION The morphology of the powder studied by an SEM showed microspheres of diameters in the range 0.5 – 10 mm (Fig. 2a ). This was confirmed by laser diffraction, which found microsphere diameters in the range 0.5 – 10 mm. A detailed analysis of the microsphere structure using a TEM revealed hollow microspheres of Ni and Fe oxides, the walls of which were constructed of 20-nm particles (Fig. 2b and 2c). XPA of the synthesized powders detected NiO and NiFe2O4 phases (Fig. 3). This phase composition corresponded to the Fe2O3–NiO phase diagram. The coherent scattering region (CSR) calculated from the XPA data was ~15 nm. The specific surface area (SSA) of the samples was 70 m2/g. The average particle size calculated from the SSA data using the equation Dav = 6/(rS) was 15 nm, where r is the theoretical density (kg/m3) and S, the measured SSA (m2/kg). Fig. 2. SEM (a) and TEM photomicrographs (b ) of NiO and FeNi2O4 synthesized at 1000°C. 650 Fig. 3. XPA of a mixture of oxides after spray pyrolysis at 1000°C. B. B. Khaidarov, A. G. Yudin, D. S. Suvorov, et al. Fig. 5. XFA of Ni3Fe after heat treatment in an H2 atmosphere. Fig. 4. Thermogravimetric data for heat treatment in the range 25 – 1000°C in an H2 atmosphere. Fig. 6. TEM images of Ni3Fe microspheres. Thermogravimetric data showed several transformations upon heating in an H2 atmosphere (Fig. 4). The first was metallization of NiO at 250°C; the second, which began at 450°C, was related to metallization of NiFe2O4. This temperature was chosen as the metallization temperature. The samples were metallized in a tube furnace in an H2 atmosphere at 450°C followed by passivation. XPA data for the metallized samples showed the single phase Ni3Fe (Fig. 5). The calculated crystallite size was close to 16 nm. The SSA of the samples was 21 m2/g; the calculated particle size, 33 nm. TEM images showed particle sizes in the range 40 – 60 nm (Fig. 6). The particle size calculated from the SSA data agreed with the TEM data. The thin oxide film Hollow Nanostructured Ni3Fe Microspheres Obtained by Spray Pyrolysis 651 REFERENCES Fig. 7. Field dependence of Ni3Fe nanostructured samples. formed after passivation was clearly visible (Fig. 7a ). The magnetic properties of Ni3Fe were studied using pressed powder and a vibrating magnetometer. Figure 7 shows hysteresis loops of Ni3Fe microspheres at room temperature. The measurement of the magnetic properties of the nanopowders showed a symmetric hysteresis loop with ferromagnetic behavior and coercive force m0Hc = 35 mT and saturation magnetization Ms = 60 A·m2·kg(1. It is noteworthy that Ni3Fe showed significantly increased magnetic coercivity as compared to bulk Ni3Fe (m0Hc = 0.054 mT). This was related to most alloy nanoparticles reaching the typical size of a single-domain state (dcr ~ 20 nm), where Hc reaches a maximum. The saturation magnetization of the nanostructured Ni3Fe samples turned out to be less than the corresponding bulk values. The decrease in the saturation magnetization together with the decrease in the particle size led to an increase in the fraction of the noncollinear magnetic structure in which magnetic moments were not equalized along the direction of the external magnetic field. This increase in the fraction of the noncollinear structure decreased the saturation magnetization. CONCLUSION Hollow Ni3Fe microspheres with diameters in the range 0.5 – 10 mm were synthesized by USP. The Ni3Fe phase was produced by metallization of the spray-pyrolysis products in an H2 atmosphere. The microsphere shells were constructed of nanoscale particles of diameters 40 – 60 nm with a crystallite size of 16 nm. The wall thickness of the microspheres was close to 100 nm. The magnetic properties of Ni3Fe showed that the obtained material was magnetically hard. The results indicated that the synthesis of nanostructured materials based on Ni–Fe with a homogeneous chemical composition and narrow microsphere size distribution was promising. 1. T. F. Marinca, H. F. Chicinas, B. V. Neamtu, et al., “Composite magnetic powder of Ni3Fe/Fe3O4 type obtained from Fe/NiO/Fe2O3 mixtures by mechanosynthesis and annealing,” J. Alloys Compd., 714, 484 – 492 (2017); DOI: 10.1016/ j.jallcom.2017.04.263. 2. T. F. Marinca, H. F. Chicinas, B. V. Neamtu, et al., “Structural, thermal and magnetic characteristics of Fe3O4/Ni3Fe composite powder obtained by mechanosynthesis-annealing route,” J. Alloys Compd., 652, 313 – 321 (2015); DOI: 10.1016/ j.jallcom.2015.08.249. 3. D. M. Fouad, W. A. El-Said, and M. B. Mohamed, “Spectroscopic characterization of magnetic Fe3O4@Au core shell nanoparticles,” Spectrochim. Acta, Part A, 140, 392 – 397 (2015); DOI: 10.1016/j.saa.2014.12.097. 4. V. Zhukova, O. A. Korchuganova, A. A. Aleev, et al., “Effect of annealing on magnetic properties and structure of Fe-Ni based magnetic microwires,” J. Magn. Magn. Mater., 433, 278 – 284 (2017); DOI: 10.1016/j.jmmm.2017.03.028. 5. M. Vazquez, H. Chiriac, A. Zhukov, et al., “On the stateof-the-art in magnetic microwires and expected trends for scientific and technological studies,” Phys. Status Solidi A, 208, 493 – 501 (2011); DOI: 10.1002/pssa.201026488. 6. R. Gemperle, L. Kraus, and J. Schneider, “Magnetization reversal in amorphous (Fe1–xNix)80P10B10 microwires,” Czech J. Phys. B, 28, 1138 – 1145 (1978); DOI: 10.1007/BF01602803. 7. A. Zhukov, M. Ipatov, and V. Zhukova, “Advances in giant magnetoimpedance of materials,” in: Handbook of Magnetic Materials, K. H. J. Buschow (ed.), 24, 139 – 236 (2015); DOI: 10.1016/bs.hmm.2015.09.001. 8. H. Chiriac, S. Corodeanu, M. Lostun, et al., “Magnetic behavior of rapidly quenched submicron amorphous wires,” J. Appl. Phys., 107(9), 09A301 (2010); DOI: 10.1063/1.3334168. 9. X. Sun, X. Zhang, P. Wang, et al., “Evolution of structure and magnetism from NixFe3–xO4 (x = 0, 0.5, 1 and 1.5) to Ni–Fe alloys and to Ni–Fe–N,” Mater. Res. Bull., 95, 261 – 266 (2017); DOI: 10.1016/j.materresbull.2017.07.030. 10. H.-R. Ren, J.-T. Gao, Z. Wang, et al., “Evolution of microstructure, mechanical and magnetic properties of electrodeposited 50% Ni–Fe alloy foil after thermal treatment,” J. Iron Steel Res. Int., 24(8), 844 – 851 (2017); 10.1016/S1006706X(17)30125-5. 11. N. Tamaekong, C. Liewhiran, A. Wisitsoraat, et al., “Flame-spray-made undoped zinc oxide films for gas sensing applications,” Sensors, 10(8), 7863 – 7873 (2010); DOI: 10.3390/s100807863. 12. P. Nunes, B. Fernandes, E. Fortunato, et al., “Performances presented by zinc oxide thin films deposited by spray pyrolysis,” Thin Solid Films, 337(1 – 2), 176 – 179 (1999); DOI: 10.1016/S0040-6090(98)01394-7. 13. V. Fauzia, M. N. Yusnidar, L. H. Lalasari, et al., “High figure of merit transparent conducting Sb-doped SnO2 thin films prepared via ultrasonic spray pyrolysis,” J. Alloys Compd., 720, 79 – 85 (2017); DOI: 10.1016/j.jallcom.2017.05.243. 14. S. Gupta, B. C. Yadav, P. K. Dwivedi, et al., “Microstructural, optical, and electrical investigations of Sb-SnO2 thin films deposited by spray pyrolysis,” Mater. Res. Bull., 48(9), 3315 – 3322 (2013); DOI: 10.1016/j.materresbull.2013.05.001. 15. P. Yao, “Effects of Sb doping level on the properties of Ti/SnO2–Sb electrodes prepared using ultrasonic spray pyrolysis,” Desalination, 267(2 – 3), 170 – 174 (2011); DOI: 10.1016/ j.desal.2010.09.021. 652 16. R. Singh, M. Kumar, S. Shankar, et al., “Effects of Sb, Zn doping on structural, electrical, and optical properties of SnO2 thin films,” Mater. Sci. Semicond. Process., 31, 310 – 314 (2015); DOI: 10.1016/j.mssp. 2014.12.010. 17. A. R. Babar and K. Y. Rajpure, “Effect of intermittent time on structural, optoelectronic, luminescence properties of sprayed antimony doped tin oxide thin films,” J. Anal. Appl. Pyrolysis, 112, 214 – 220 (2015); DOI: 10.1016/j.jaap. 2015.01.024. 18. S. Gurakar, T. Serin, and N. Serin, “Studies on optical properties of antimony doped SnO2 films,” Appl. Surf. Sci., 352, 16 – 22 (2015); DOI: 10.1016/j.apsusc.2015.03.057. 19. N. Wongcharoen and T. Gaewdang, “Co-existence of F and Sb dopants in transparent conducting SnO2 thin films prepared by ultrasonic spray pyrolysis method,” in: Proceedings of ISES World Congress 2007: Solar Energy and Human Settlement, 2009, Vol. 1, pp. 1269 – 1274; DOI: 10.1007/978-3-54075997-3 256. 20. E. A. Ramirez, A. Ramirez, and G. Gordillo, “Cu2ZnSnS4 films grown in one-step process by spray pyrolysis with improved properties,” Mater. Sci. Semicond. Process., 67, 110 – 117 (2017); DOI: 10.1016/j.mssp.2017.05.024. 21. H. Katagiri, K. Jimbo, S. Yamada, et al., “Enhanced conversion efficiencies of Cu2ZnSnS4-based thin film solar cells by using preferential etching technique,” Appl. Phys. Express, 1, 4, Art. 041201 (2008); DOI: 10.1143/APEX.1.041201. 22. D. A. R. Barkhouse, O. Gunawan, T. Gokmen, et al., “Device characteristics of a 10.1% hydrazine-processed Cu2ZnSn(Se, S)4 solar cell,” Prog. Photovoltaics, 20, 6 – 11 (2012); DOI: 10.1002/pip. 1160. 23. T. K. Todorov, J. Tang, S. Bag, et al., “Beyond 11% efficiency: Characteristics of state-of-the-art Cu2ZnSn(S,Se)4 solar cells,” Adv. Energy Mater., 3(1), 34 – 38 (2013); DOI: 10.1002/ aenm.201200348. 24. S. M. Menaka, G. Umadevi, and M. Manickam, “Effect of copper concentration on the physical properties of copper doped NiO thin films deposited by spray pyrolysis,” Mater. Chem. Phys., 191, 181 – 187 (2017); DOI: 10.1016/j.matchemphys. 2017.01.048. 25. R. Vehring, “Pharmaceutical particle engineering via spray drying,” Pharm. Res., 25(5), 999 – 1022 (2008); DOI: 10.1007/ s11095-007-9475-1. 26. W. Widiyastuti, W.-N. Wang, I. W. Lenggoro, et al., “Simulation and experimental study of spray pyrolysis of polydispersed droplets,” J. Mater. Res., 22(7), 1888 – 1898 (2007); DOI: 10.1557/jmr.2007.0235. 27. K. Okuyama, M. Abdullah, I. W. Lenggoro, et al., “Preparation of functional nanostructured particles by spray drying,” Adv. Powder Technol., 17(6), 587 – 611 (2006); DOI: 10.1163/ 156855206778917733. 28. H. W. Chang and K. Okuyama, “Optical properties of dense and porous spheroids consisting of primary silica nanoparticles,” J. Aerosol Sci., 33(12), 1701 – 1720 (2002); DOI: 10.1016/ S0021-8502(02)00116-7. 29. M. Pal, L. Wan, Y. Zhu, et al., “Scalable synthesis of mesoporous titania microspheres via spray-drying method,” J. Colloid Interface Sci., 479, 150 – 159 (2016); DOI: 10.1016/ j.jcis.2016.06.063. B. B. Khaidarov, A. G. Yudin, D. S. Suvorov, et al. 30. F. Iskandar, “Nanoparticle processing for optical applications (A review,” Adv. Powder Technol., 20(4), 283 – 292 (2009); DOI: 10.1016/j.apt.2009.07.001. 31. T. Ogi, Y. Kaihatsu, F. Iskandar, et al., “Synthesis of nanocrystalline GaN from Ga2O3 nanoparticles derived from salt-assisted spray pyrolysis,” Adv. Powder Technol., 20(1), 29 – 34 (2009); DOI: 10.1016/j.apt.2008.10.005. 32. Mikrajuddin, F. Iskandar, K. Okuyama, et al., “Stable photoluminescence of zinc oxide quantum dots in silica nanoparticles matrix prepared by the combined sol-gel and spray drying method,” J. Appl. Phys., 89(11), 6431 – 6434 (2001); DOI: 10.1063/1.1360706. 33. F. Iskandar, Mikrajuddin, and K. Okuyama, “In situ production of spherical silica particles containing self-organized mesopores,” Nano Lett., 1(5), 231 – 234 (2001); DOI: 10.1021/nl0155227. 34. F. Iskandar, H. W. Chang, and K. Okuyama, “Preparation of microencapsulated powders by an aerosol spray method and their optical properties,” Advanced Powder Technology, 14(3), 349 – 367 (2003); DOI: 10.1163/15685520360685983. 35. S. Freitas, H. P. Merkle, and B. Gander, “Ultrasonic atomization into reduced pressure atmosphere-envisaging aseptic spray-drying for micro-encapsulation,” J. Controlled Release, 95(2), 185 – 195 (2004); DOI: 10.1016/j.jconrel.2003.11.005. 36. J.-S. Gong and W.-B. Fu, “The experimental study on the flow characteristics for a swirling gas–liquid spray atomizer,” Appl. Therm. Eng., 27, 2886 – 2892 (2007); DOI: 10.1016/ j.applthermaleng.2007.04.006. 37. P. D. Hede, P. Bach, and A. D. Jensen, “Two-fluid spray atomization and pneumatic nozzles for fluid bed coating/agglomeration purposes: A review,” Chem. Eng. Sci., 63(14), 3821 – 3842 (2008); DOI: 10.1016/j.ces.2008.04.014. 38. B. Ksapabutr, P. Nimnuan, and M. Panapoy, “Dense and uniform NiO thin films fabricated by one-step electrostatic spray deposition,” Mater. Lett., 153, 24 – 28 (2015); DOI: 10.1016/ j.matlet.2015.03.151. 39. J.-b. Xie, C.-m. Wen, G.-y. Qin, et al., “AgNi15 composite particles prepared by ultrasonic arc spray atomization method,” Trans. Nonferrous Met. Soc. China, 24(11), 3556 – 3561 (2014); DOI: 10.1016/S1003-6326(14)63501-9. 40. L. Yuan, “Ignition of hydraulic fluid sprays by open flames and hot surfaces,” J. Loss Prev. Process Ind., 19(4), 353 – 361 (2006); DOI: 10.1016/j.jlp. 2005.09.001. 41. A. B. D. Nandiyanto and K. Okuyama, “Progress in developing spray-drying methods for the production of controlled morphology particles: From the nanometer to submicrometer size ranges,” Advanced Powder Technology, 22(1), 1 – 19 (2011); DOI: 10.1016/j.apt.2010.09.011. 42. A. Yudin, N. Shatrova, B. Khaydarov, et al., “Synthesis of hollow nanostructured nickel oxide microspheres by ultrasonic spray atomization,” J. Aerosol Sci., 98, 30 – 40 (2016); DOI: 10.1016/j.jaerosci.2016.05.003. 43. N. Shatrova, A. Yudin, V. Levina, et al., “Elaboration, characterization and magnetic properties of cobalt nanoparticles synthesized by ultrasonic spray pyrolysis followed by hydrogen reduction,” Mater. Res. Bull., 86, 80 – 87 (2017); DOI: 10.1016/ j.materresbull.2016.10.010.