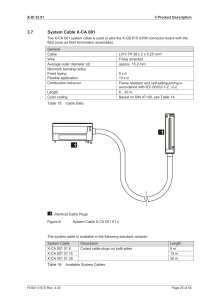

Universal LINC232 INSTALLATION MANUAL NEW RELEASE Form 450.20-N17 (702) Universal LINC232 Universal LINC232 UCS UNIVERSAL LINC232 UCS STATUS OFF CTS GND TX RX TX RX RS232 P1 P2 OFF OFF ON OFF OFF ON ON ON PARITY NONE SPACE ODD EVEN B1 B2 OFF OFF ON OFF OFF ON BAUD 4800 9600 19K2 CS OFF 19K2 LAN CS ON 50K LAN P1 P2 B1 B2 1 2 4 8 16 32 64 CS ON SCREEN P3 P2 GND RX 5VDC TX LAN FORM 450.20-N17 (702) IMPORTANT! READ BEFORE PROCEEDING! GENERAL SAFETY GUIDELINES During installation, operation, maintenance or service, individuals may be exposed to certain components or conditions including, but not limited to: refrigerants, oils, materials under pressure, rotating components, and both high and low voltage. Each of these items has the potential, if misused or handled improperly, to cause bodily injury or death. It is the obligation and responsibility of operating/ service personnel to identify and recognize these inherent hazards, protect themselves, and proceed safely in completing their tasks. Failure to comply with any of these requirements could result in serious damage to the equipment and the property in which it is situated, as well as severe personal injury or death to themselves and people at the site. This document is intended for use by owner-authorized operating/service personnel. It is expected that this individual possesses independent training that will enable them to perform their assigned tasks properly and safely. It is essential that, prior to performing any task on this equipment, this individual shall have read and understood this document and any referenced materials. This individual shall also be familiar with and comply with all applicable governmental standards and regulations pertaining to the task in question. SAFETY SYMBOLS The following symbols are used in this document to alert the reader to areas of potential hazard: 2 DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. CAUTION identifies a hazard which could lead to damage to the machine, damage to other equipment and/or environmental pollution. Usually an instruction will be given, together with a brief explanation. WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury. NOTE is used to highlight additional information which may be helpful to you. YORK INTERNATIONAL FORM 450.20-N17 (702) CHANGEABILITY OF THIS DOCUMENT In complying with YORK’s policy for continuous product improvement, the information contained in this document is subject to change without notice. While YORK makes no commitment to update or provide current information automatically to the manual owner, that information, if applicable, can be obtained by contacting the nearest YORK Sales, Service and Authorized Distributor offices. It is the responsibility of operating/service personnel as to the applicability of these documents. If there is any question in the mind of operating/service personnel as to the applicability of these documents, then, prior to working on the equipment, they should verify with the owner whether the equipment has been modified and if current documentation is available. REFERENCE INSTRUCTIONS DESCRIPTION Universal LINC232 Specification Sheet YORK INTERNATIONAL FORM NO. 450.20-S29 3 FORM 450.20-N17 (702) TABLE OF CONTENTS GENERAL SAFETY GUIDELINES .......................................................................................................... 2 SAFETY SYMBOLS ................................................................................................................................ 2 REFERENCE INSTRUCTIONS ............................................................................................................... 3 LIST OF FIGURES .................................................................................................................................. 6 LIST OF TABLES..................................................................................................................................... 6 SECTION 1 – GENERAL INFORMATION ............................................................................................... 7 Overview ............................................................................................................................................ 7 Description ................................................................................................................................... 7 SECTION 2 – NETWORK TOPOLOGY .................................................................................................. 9 General .............................................................................................................................................. 9 Communication Method ..................................................................................................................... 9 Background vs. Foreground Communications ................................................................................. 11 Speed of Communications............................................................................................................... 11 Summary of ISN Network Restrictions ............................................................................................ 11 SECTION 3 – INSTALLATION ............................................................................................................... 13 Installation Guidelines ...................................................................................................................... 13 Environment ............................................................................................................................... 13 Electrical ..................................................................................................................................... 13 Electrical Noise .......................................................................................................................... 13 Ground/Earth ............................................................................................................................. 14 Protection of Communication Ports ........................................................................................... 14 Cable Specifications ........................................................................................................................ 14 Power Cables ............................................................................................................................. 14 Network and Sensor Cables ...................................................................................................... 14 Summary of Mounting Recommendations ................................................................................ 16 Hardware Configuration ................................................................................................................... 16 DIN Rail Mounting ...................................................................................................................... 16 Panel Mounting .......................................................................................................................... 16 Power Connections .......................................................................................................................... 17 Universal LINC Connection ........................................................................................................ 17 5 VDC Power Supply Connection .............................................................................................. 17 4 YORK INTERNATIONAL FORM 450.20-N17 (702) TABLE OF CONTENTS (CONTINUED) Wire Connections ............................................................................................................................. 19 RS232 Connection ..................................................................................................................... 19 LAN Connection ......................................................................................................................... 19 Switch Settings ................................................................................................................................ 20 Continuity and Isolation Checks ...................................................................................................... 24 SECTION 4 – MAINTENANCE .............................................................................................................. 25 LEDs ................................................................................................................................................ 25 Status LED ................................................................................................................................. 25 Port LEDs ................................................................................................................................... 25 APPENDIX ............................................................................................................................................. 28 Universal LINC232 Specifications ................................................................................................... 28 YORK INTERNATIONAL 5 FORM 450.20-N17 (702) LIST OF FIGURES Figure 1. Universal LINC232 ................................................................................................................................ 8 Figure 2. Typical Network Configurations ........................................................................................................... 10 Figure 3. DIN Rail Mounting Options .................................................................................................................. 16 Figure 4. DIN Rail Removal ................................................................................................................................ 17 Figure 5. USB-Style Patch Cable ....................................................................................................................... 17 Figure 6. Dimensions and Mounting Points ........................................................................................................ 18 Figure 7. Typical RS232 Wire Connection .......................................................................................................... 20 Figure 8. Typical RS485 LAN Connections ......................................................................................................... 21 Figure 9. Universal LINC232 Components ......................................................................................................... 22 Figure 10. Universal LINC232 DIP Switch Settings ............................................................................................ 23 LIST OF TABLES Table 1 – Recommended Cable Specifications .................................................................................................. 15 Table 2 – Recommended Parity Settings............................................................................................................ 20 6 YORK INTERNATIONAL GENERAL INFORMATION FORM 450.20-N17 (702) SECTION 1 GENERAL INFORMATION Overview The Universal LINC232 allows peripheral devices to be attached to the ISN network to receive and send data. The Universal LINC232 provides a connection point for: VT100 Terminal Emulation (PC connection) Modem Printer 1 Along with this upgrade some of the switches were modified and the baud rates were upgraded to offer higher speeds. These items are covered more specifically in the Installation section. NOTE: This manual will refer to both versions as the Universal LINC232 unless specific differences apply. When specific differences in operation apply, they will be referenced at that time. Facility Manager/YES/IcE/TUP/ISNTools A variety of mounting configurations provide a very adaptable device. A 5 VDC Power Supply is also available to power the Universal LINC232 or it can be powered via the LAN connector on newer controllers equipped with a USB-style connector. The power supply also includes the same flexible mounting options as the Universal LINC232. The original Universal LINC232 was designed around the Rev. 77 and older networks. While communication to newer, UCS-based products (TDCE, IDC, UDC, etc.) is functional, the save or restore functions within Facility Manager did not operate correctly. The IcE engineering tool also does not accommodate the UDC software in the on-line edit mode or the save and restore functions. To accommodate products using the newer UCS software, the Universal LINC232 was enhanced. This product is differentiated from the original by the name “Universal LINC232 UCS” on the metalwork or the printed circuit board number of 031-02424-001. NOTE: The Universal LINC232 supports on-line monitoring only and does not support remote alarm delivery. For remote alarm delivery, a LINC Guardian Modem is required. The Universal LINC232 uses a bank of DIP switches to select communication parameters and node address. The selectable communication parameters are parity and transfer rate. NOTE: The Universal LINC232 can only be powered via the LAN connection on products equipped with a USBstyle connector. Products not equipped with the USB-style connector must be powered from the optional 5 VDC Power Supply. The Universal LINC232 requires a 5 VDC power source. If located within 39 in. (1 m) of a controller equipped with the USB-style connector, sufficient power can be supplied through the LAN connection point, either the screw terminals or USB-style connector. For older style controllers, i.e., those not equipped with a USB-style connector, or if the mounting location is not within 39 in. (1 m) of any controller, the 5 VDC Power Supply must be used to power the Universal LINCs. Description The Universal LINC232 is a small footprint device which can be located inside most enclosures or positioned as a stand-alone device within a building. The Universal LINC232, as well as the optional 5 VDC Power Supply, includes a housing with a DIN rail mounting clip. Either device can be removed from the housing and attached directly to a panel or YORK INTERNATIONAL 7 GENERAL INFORMATION FORM 450.20-N17 (702) Universal LINC232 UNIVERSAL LINC232 UCS STATUS OFF CTS GND TX RX TX RX PARITY NONE SPACE ODD EVEN B1 B2 OFF OFF ON OFF OFF ON BAUD 4800 9600 19K2 CS OFF 19K2 LAN CS ON 50K LAN RS232 Plastic Housing P1 P2 OFF OFF ON OFF OFF ON ON ON P1 P2 B1 B2 1 2 4 8 16 32 64 CS Universal LINC232 ON SCREEN P3 TX P2 GND RX 5VDC LAN DIP Switches Plastic Housing DIN Rail Mounting Figure 1. Universal LINC232 enclosure. In addition, if the power supply is used, the LINC can attach to the power supply in a “piggyback” style. ing power supply. The enclosure also works for mounting other YORK devices, such as a TDC8E or TDC9E. An enclosure with a DIN rail is also available as a mounting option. This enclosure provides for easy installation of one Universal LINC and accompany- The Universal LINC232 has two ports. The LAN port always connects to the LAN or controller. The RS232 port always connects to the RS232 device. Two LEDs indicate communication status for each port. A single STATUS LED indicates the condition of the device. 8 YORK INTERNATIONAL NETWORK TOPOLOGY FORM 450.20-N17 (702) SECTION 2 NETWORK TOPOLOGY General The full range of ISN control products (UDC, TDCE, FDC, etc.) are able to reside on a Local Area Network (LAN) with full peer-to-peer communications. The network architecture supports a potential of 8372 controllers, each one able to communicate to any number of other controllers on the LAN and outside of the LAN via a modem to remote facilities. The entire building or complex may be linked together to form a Building Automation System (BAS) or Building Management System (BMS). YORK’s proprietary network protocol is the Integrated System Network (ISN). The ISN network is RS485, utilizing ethernet principles and background and foreground communication levels. The data transfer speed is either 19.2 or 50 kbaud, depending upon the version of software used. Newer versions of software allow transfer speed selection to be backward-compatible with older networks. All ISN controllers have the ability to communicate directly to all other ISN controllers or devices on a network or any subnetwork – this is known as “peer to peer” communication. Due to the volume of traffic which may be present on a network, it is often beneficial to divide the network into subnetworks. Local messages remain contained within the subnetwork. Full network communication is then limited to only the data relevant to the other subnetworks, greatly reducing the network traffic. A variety of devices may be attached to the ISN network to enhance usability and functionality. Some of these devices are: • The Universal LINC485 configured as a repeater amplifies the network signal to extend the physical length of a network or subnetwork cable. They also extend the number of ISN controllers by segmenting the network. • The Universal LINC485 configured as a router separates subnetworks from the main network. • The LINC Fiber Optics interfaces the ISN network with fiber optic cable. YORK INTERNATIONAL • The LINC Guardian manages the remote transmission of multiple alarms from the ISN network. • The Universal LINC232 allows communication to RS232 devices such as modems, serial printers, terminals or PC’s. 2 NOTE: The PC must be running a VT100 emulation program, York Icon Engineering Software (IcE) or York Facility Manager for Windows™ software. Physically, a twisted-pair (2-core) shielded cable is daisy-chained between the network devices. Communication Method The ISN network communicates on a “contention” basis. Every ISN controller on the network can transmit a message but only the designated receiving controller(s) acknowledge receipt. Each receiving controller sends a receipt back to the sending controller as acknowledgment of the transmission. A calculated checksum is used to verify the integrity of each message. If no acknowledgment is received, the message is automatically retransmitted up to 3 times. After 3 attempts to communicate, the sending controller starts to increase the amount of time between transmissions. The time increases in intervals of 10 seconds, 15 seconds, 30 seconds, 1 minute, 15 minutes, 30 minutes and then 1 hour if unsuccessful. Retransmission of the message then occurs automatically every hour until receipt is acknowledged. No message is ever lost, although message delivery may be slowed on high traffic networks if not segmented properly. If an external device is connected to the RS232 port, such as a modem through the Universal LINC232, the retransmission interval between failed communications changes from 1 minute to 15 minutes to 30 minutes to 1 hour, 2 hours, 4 hours and then 6 hours. Retransmission of the message then automatically occurs every 6 hours until receipt is acknowledged. 9 NETWORK TOPOLOGY FORM 450.20-N17 (702) Subnetwork TM ISN YORK Ò TM ISN Repeater Router UNIVERSAL LINC485 UNIVERSAL LINC485 Controller Controller Repeater UNIVERSAL LINC485 Router UNIVERSAL LINC485 Universal LINC485 w/ Power Supply UNIVERSAL LINC485 Universal LINC485 w/ Power Supply Controller Universal LINC485 w/ Power Supply Controller Router Repeater UNIVERSAL LINC485 UNIVERSAL LINC232 UNIVERSAL LINC485 Universal LINC485 w/ Power Supply Universal LINC485 w/ Power Supply Segment Modem Universal LINC232 w/ Power Supply Universal LINC485 w/ Power Supply Repeater Maximum of 30 nodes and 4000 ft. (1220 m) Base Network Controller Universal LINC485 w/ Power Supply Base Network Universal LINC485 w/ Power Supply UNIVERSAL LINC485 Ò Repeater YORK Controller Repeater Controller UNIVERSAL LINC485 Universal LINC232 Facility Manager USB Cable UNIVERSAL LINC232 Universal LINC485 w/ Power Supply Base Network Maximum of 91 nodes and 12,000 ft. (3660 m) UNIVERSAL LINC232 Printer Universal LINC232 w/ Power Supply Figure 2 – Typical Network Configurations 10 YORK INTERNATIONAL NETWORK TOPOLOGY FORM 450.20-N17 (702) Background vs. Foreground Communications The ISN network uses both “Background” and “Foreground” communication to ensure essential data is transmitted without delay. Background communication supports multiple source messages at the same time, although the speed of communication may be affected if large quantities of data are transmitted around the network. Examples of background communication are: • Automatic transfer of digital states and analog values between ISN controllers. • Analog and Digital alarms to a Universal LINC232 connected to a PC running the York Facility Manager for Windows™ software. • Using a PC running the York Facility Manager for Windows™ software to read and write data to and from an ISN controller via a Universal LINC232. • Analog and Digital alarms to a LINC Guardian. Only one foreground communication to a specific ISN controller can occur at any one time. A “busy” message is displayed if the ISN controller is already communicating with another device using this method. Background communication can occur simultaneously with foreground communication. Examples of foreground communications are: • Manual communications between ISN controllers using the optional keypad/display or Windows™ HyperTerminal software running on a PC connected to the RS232 port of an ISN controller. • Using a PC running the York Facility Manager for Windows™ software to write data into an ISN controller via a Universal LINC232. • Printing of Analog and Digital alarms to a Universal LINC232 connected to an RS232 printer. YORK INTERNATIONAL • Using a PC running the York IcE to Save or Load an ISN controller Configuration via a Universal LINC232. • Using a PC running the York Facility Manager for Windows™ to Save or Load an ISN controller Configuration via a Universal LINC232. Speed of Communications The ISN network communicates at either a 19.2 or 50 kbaud rate. The Universal LINC232 is switch selected to communicate at 4800, 9600, or 19,200 (19k2) baud rates through the serial RS232 port. The typical response time between ISN controllers for automatic transfer of data or alarms is 100 milliseconds. Each Universal LINC485 Repeater and Router increases the typical response time by 100 milliseconds. Summary of ISN Network Restrictions • The maximum single length of a network or subnetwork is 4000 ft. (1200 m). This can be extended to 12,000 ft. (3600 m) using two Universal LINC485 devices configured as repeaters. This provides a maximum combined network end-to-end length of 36,000 ft. (10,800 m). • A Universal LINC485 configured as a repeater is required every 4000 ft. (1200 m) or 32 nodes. A node is any device which uses an RS485 driver, such as an ISN controller, Universal LINC485 or Universal LINC232. • The maximum number of nodes on a main network is 92 plus two Universal LINC485 devices configured as repeaters. A maximum of 91 plus two Universal LINC485 devices are allowed on a subnetwork. • When the main network or subnetworks are extended between different buildings, the ground/earth voltage of the buildings must be at 11 2 NETWORK TOPOLOGY FORM 450.20-N17 (702) the same potential. If this cannot be guaranteed, the network connection between building(s) should be a fiber optic cable with a LINC Fiber Optic device fitted in each building to interface onto the ISN network. • The LINC Guardian should be used where it is expected multiple alarms will be transmitted via a modem to a remote Facility Manager for Windows™ or multiple destinations. It acknowledges receipt of any alarm to a transmitting ISN controller and can store up to 20 alarms in each of the 8 standard ISN Alarm Classes. • All node numbers connected to the LAN Port 1 of a Universal LINC485 configured as a repeater must be lower than the node address of the repeater. All node numbers connected to the 12 LAN Port 2 of a Universal LINC485 configured as a repeater must be higher than the node address of the repeater. • Each ISN controller must have the node switch set to a unique address number between 1 and 98 per subnetwork. The node switches are used for filtering messages at a Universal LINC485 configured as a repeater which also must have a unique node number. The node switches on a Universal LINC485 configured as a router set the subnetwork address and must be between 1 and 98, with the main network automatically being network address 99. Communications between ISN devices on the same network or subnetwork(s) should use network 0 (zero) as the network address. YORK INTERNATIONAL INSTALLATION FORM 450.20-N17 (702) SECTION 3 INSTALLATION Installation Guidelines This manual assumes the installer is competent in environments with moving machinery, and is able to recognize and protect against any inherent hazards, such as, but not limited to, refrigerants, oil, corrosive chemicals or gases, materials under pressure, rotating parts, and both high and low voltages. Each of these items has the potential, if misused or handled improperly, to cause bodily injury or death. It is the obligation and responsibility of the operating/ service personnel to identify and recognize inherent hazards, protect themselves, and proceed safely in completing their tasks. Failure to comply with any of these requirements could result in serious damage to the equipment, as well as severe personal injury or death. In addition to following standard local, state and country codes and procedures, it is recommended that a lockout procedure be used to prevent inadvertent start up of equipment during installation and maintenance procedures. All wiring should be carried out in a safe and neat manner and should always comply in all respects to the latest edition of any local, state or country codes that may be applicable. The wiring should be installed in a manner that does not cause a hazard and is protected against electrical and mechanical damage. Care should also be taken when mounting enclosures so access to other equipment within the vicinity is not restricted. Environment YORK ISN equipment must be installed in an environment that is protected from the direct influence of the elements and is within the following: Temperature: 32 to 122° F (0 to 50° C). Humidity: 10% to 95% non-condensing. The unit should never be mounted outside the confines of a building. If this cannot be avoided, it may be mounted inside an enclosure rated at IP65/NEMA 4X or greater. In addition to protection against the YORK INTERNATIONAL elements, the enclosure must be capable of maintaining the circuit boards at the required temperature and humidity. This may require the addition of a fan or heater to maintain the temperature and humidity inside the enclosure. WARNING: Never install the components in an element that does not meet the minimum environmental requirements. 3 Electrical Refer to the table titled Recommended Cable Specifications to determine suitable wire sizes to connect the line voltage feed the devices. The line voltage power source should be “clean,” separately fused (for either 110 or 240 VAC), and isolated, (using a control transformer) from other equipment in the plant room that may generate EMI interference. Electrical Noise All electrical equipment has the risk of being affected by external electrical noise. This noise may take the form of Radio Frequency Interference (RFI) or Electro-Magnetic Interference (EMI). To minimize the affects of electrical noise, mount equipment in a location away from all possible RFI and EMI sources. These include high voltage cables, high voltage transformers, breakers, and high frequency drives. Keep line voltage switching loads a minimum of 6 in. (152 mm) away. Any high voltage equipment, such as transformers, high horsepower electric motors or high frequency drives, should be kept a minimum of 30 ft. (9.1 m) away. All high voltage wiring (>75 volts) must be run in conduit and kept separate from low voltage communications wiring. This greatly reduces network communication problems. 13 INSTALLATION FORM 450.20-N17 (702) Ground/Earth All ISN controllers are designed to use the building ground (earth) as a reference point. This electrical orientation helps maintain all electronic components communicating to the controller within their specified voltage limits. Protection of Communication Ports GRD. RAM 5 CAUTION: The controller must connect to a true building ground. Failure to do so may cause equipment damage and will void all warranty claims. Electrical grounding also protects network devices from the effects of lightning strikes. When lightning strikes near an ISN installation, it alters the potential of the building’s ground. If an ISN controller has been properly grounded, it will respond to this change much faster than if the ground connection is inadequate. Controllers that are poorly grounded provide a lower resistance path through their signal or power connections than the actual ground of the building. Under these circumstances large surge currents may flow through the controller and result in component failure. An example of a poor ground would be a galvanized steel cold water pipe. As the pipe corrodes it no longer acts as a true ground. The corrosion acts as an insulator, raising the potential of the pipe with respect to earth ground. YORK strongly recommends that the building’s ground be checked prior to the start of the installation. The power distribution panel should be checked to ensure that it is not connected to a corroded or galvanized pipe. As a minimum, it must be connected with 14 AWG wire. The most common circuits damaged are communication components, such as RS485 and RS232 drivers. When using RS485 technology it is possible that electrical disturbances, such as voltage spikes, can damage a circuit board. Newer ISN controllers include tranzorbs at the RS485 ports to protect against damaging electrical spikes and stray voltage. It is recommended that all devices on an RS485 network be equipped with protection against electrical disturbance. Cable Specifications Power Cables CAUTION: Aluminum wire is absolutely not acceptable. The power cable should be at least an 18 AWG copper wire rated for 10 amps per core at 250 volt AC. If the power cable uses three conductors, the ground conductor must be, as a minimum, the same size with the same current carrying capacity as the live and neutral conductors. All ISN devices should be wired to a non-switched, fused spur to prevent the power from being turned off accidently. The supply spur should be protected with a either a suitable fuse or an approved power breaker. The input line supply voltage should be fused. For a 115-volt line voltage use a 10-amp fuse or breaker. For a 230-volt line voltage use a 5-amp fuse. The fuse or breaker should be located within a reasonable distance to the controller so the power can be turned off any time the unit is serviced. Network and Sensor Cables Cables come in many types. A balance between cost of the wire and the simplicity of the project determines the variety of wires used. Quite often a single type of wire or cable may be used for nearly all wiring on a project, even though it greatly exceeds the requirements for a particular sensor or application. 14 YORK INTERNATIONAL INSTALLATION FORM 450.20-N17 (702) Table 1 – Recommended Cable Specifications Analog, Digital, RS485 (ISN & Digital Outputs Pulse Inputs and York Talk 2 Analog Outputs Networks) RS232 (Devices to LINCs and Controllers; York Talk 1 & 3 Networks) Line Voltage Power Supply Number of Cores 2 (or n for multicore) 2 (or n for multicore) 2 Twisted 3 3 w/Outer Sheath 0.31- 0.41 in. (7.8-10.3 mm) dia. Minimum Conductor Gauge – AWG (CSA) 22 (0.34 mm2) 22 (0.34 mm2) 20 (0.52 mm2) 22 (0.34 mm2) 16 (1.5 mm2) Conductor Material Tinned Copper Tinned Copper Tinned Copper Tinned Copper Plain Copper Strand/Strand gauge AWG (CSA) 7/30 (7/0.2 mm) 7/30 (7/0.2 mm) 7/28 (16/0.2 mm) 7/30 (7/0.2 mm) 19/27 (30/0.25) Voltage Rating – Uo/U 300 300 300 300 300/600 Nominal Current per Core – amps 1 2.5 N.A. N.A. 10 Shield Unshielded 100% Overall Beldfoil Conductor Insulation Round PVC Round PVC Round PVC Round PVC PVC Core Insulation PVC PVC PVC PE PVC Nominal Capacitance between Conductors – pF/m N.A. 80 64.6 75 N.A. Characteristic Impedance – ohms N.A. N.A. 78 N.A. N.A. Maximum Run Length – ft (m) 1000 (305) 1000 (305) Refer to Section 2 32 (10) N.A. Belden Number 8442 8761 9272 9533 N.A. 100% Overall Beldfoil or 93% 100% Overall Beldfoil Overall Braided 3 N.A. N.A. – Not applicable. NOTE: Whenever possible, use cabling which meets or exceeds the equivalent of the Belden specification. The table titled Recommended Cable Specifications provides a guide to one major wire manufacturer’s product line. These are the minimum requirements. Use them as a guide. If questions arise, most wire supply companies can cross-reference between YORK INTERNATIONAL manufacturers and help determine if a particular wire meets the requirements. NOTE: Be sure cables are securely attached without tensile load. 15 INSTALLATION FORM 450.20-N17 (702) To attach any of the devices, hook the lip of the mount over the edge of the DIN rail. Press the bottom of the device until the mount “snaps” over the lower lip of the DIN rail. Summary of Mounting Recommendations • Always mount ISN devices inside the confines of a building or inside an enclosure suitably rated for exposure to weather. To remove a module, pull the lower lip of the mount, which is exposed below the housing, down until the lower lip of the DIN rail is clear. Tilt the device and lift it off the top lip of the DIN rail. • Never mount ISN devices under or beside pipes carrying water or chemicals. • Never mount ISN devices near high voltage cables, high voltage transformers or breakers, or close to high frequency drives. In some situations it may be desirable to remove the Universal LINC from the housing and attach it to the 5 VDC Power Supply. The housings are modular and can be separated by using a screwdriver pressed between sections. When the Universal LINC is removed from the housing it may be attached to the 5 VDC Power Supply using the two 2.5M x 5 screws located on the top surface of the power supply. The assembled unit may then be clipped to a DIN rail. • Never mount ISN devices in a location where the environment could be outside the specified operating specifications. • Never mount ISN devices on a vibrating surface without first employing some form of mechanical dampening. Hardware Configuration Panel Mounting DIN Rail Mounting When a DIN rail mount is not desired, the Universal LINC may be removed from the plastic housing by separating the sections of the housing. The Universal LINC may then be attached directly to a suitable panel using 1/8 in. (4 mm) screws. Likewise, the power supply may also be removed from the plastic housing and attached directly to a suitable panel. The option to attach the Universal LINC to the top of the The Universal LINC232 provides several different options for installing within a network. Each device is shipped within a plastic housing with a DIN rail mounting clip. The optional 5 VDC Power Supply also uses a plastic housing with DIN rail mounting clip. Universal LINC Universal LINC DIN Rail DIN Rail Plastic Housing Plastic Housing Power Supply Figure 3. DIN Rail Mounting Options 16 YORK INTERNATIONAL INSTALLATION FORM 450.20-N17 (702) USB-style Plug Patch Cable WHITE SCREEN GREEN RED BLACK Patch Cable Color Codes SCREEN P3 P2 GND 5VDC Universal LINC Terminations Figure 4. DIN Rail Removal Figure 5. USB-Style Patch Cable Power Supply also applies to panel mounting of the Power Supply. 5 VDC Power Supply Connection Refer to the figure titled “Dimensions and Mounting Points” for hole spacing requirements. Power Connections Universal LINC Connection Because the Universal LINC is a small device, power can be drawn from a controller if located within 39 in. (1 m) of the controller. When a Universal LINC is not located within 39 in. (1 m) of a controller a separate power supply must be used. The terminals GND and 5VDC at the LAN port should be connected directly to the 5 VDC Power Supply. An alternative method of connecting a Universal LINC is to use a patch cable (Part No. 371-01429-000). This patch cable takes advantage of the additional, USB-style connector on the newer controllers. The patch cable combines the power and communication wires into a single cable and doesn’t require disconnection of the existing network cables from the standard LAN connector. 3 The optional 5 VDC Power Supply is supplied as either 115 or 230 ±10% volts AC at 50/60 Hz frequencies. Maximum output of the Power Supply Module is 300 mA at 5 volts DC. A properly color-coded wire must be obtained locally to conform to local, state and country regulations for connection of the 115/230 VAC line voltage. Two leads, red and black, from the power supply connect to the Universal LINC. DANGER: Disconnect any line voltage power supply at the source before attaching wiring to prevent possible electrocution. The line voltage power supply should be wired to a non-switched fused spur to prevent the power from being turned OFF accidentally. A fuse or breaker rated at 5 amps (115 VAC input) or 3 amps (230 VAC input) should protect the controller from overload. The 5 VDC Power Supply requires a 3-conductor, power cable for the line voltage power supply, similar to the one used by most computers. It may use a typical plug in connector (ideal for connecting to the Auxiliary Power Outlet in a UDC) or have bare wire YORK INTERNATIONAL 17 INSTALLATION 0.16 in. (4 mm) FORM 450.20-N17 (702) 0.58 in. (15 mm) 0.58 in. (15 mm) 2.48 in. (63 mm) 0.98 in. (25 mm) A UNIVERSAL LINC232 UCS STATUS CTS GND TX RX TX RX RS232 PARITY NONE SPACE ODD EVEN B1 B2 OFF OFF ON OFF OFF ON BAUD 4800 9600 19K2 P1 P2 B1 B2 1 2 4 8 16 32 64 CS CS OFF 19K2 LAN CS ON 50K LAN 2.75 in. (70 mm) 2.32 in. (59 mm) OFF ON P1 P2 OFF OFF ON OFF OFF ON ON ON SCREEN P3 TX P2 GND RX 5VDC LAN OFF ON 0.16 in. (4 mm) A 2.16 in. (55 mm) on DIN rail 3.93 in. (100 mm) 0.51 in. (13 mm) 0.51 in. (13 mm) 2.48 in. (63 mm) B 0.16 in. (4 mm) Optional Power Supply 1.77 in. (45 mm) Universal LINC232 3.66 in. (93 mm) C B A – Mounting Hole for Universal LINC; 0.16 in. (4 mm) diameter B – Mounting Hole for Power Supply; 0.16 in. (4 mm) diameter C – 2.5M x 5 stud for mounting Universal LINC on Power Supply Power Supply Mounting Plate 0.16 in. (4 mm) C 2.95 in. (75 mm) on DIN rail Figure 6. Dimensions and Mounting Points 18 YORK INTERNATIONAL INSTALLATION FORM 450.20-N17 (702) at the other end (for connection to a circuit breaker box). It is recommended that the line voltage supply cable be installed within suitable conduit if it is run outside the enclosure. Ensure that all wiring meets local, state and country codes, as well as follows NEC recommendations. To install the Power Supply Module: DANGER: Always disconnect the power before working inside or around an electrical enclosure. 1. Mount the 5 VDC Power Supply using either the DIN rail or panel mounting method. 2. Attach the black power lead from the 5 VDC Power Supply to the GND terminal and the red power lead to the 5 VDC terminal of the LAN port. 3. Install conduit, if necessary to meet code, between the device and an appropriate line voltage power supply at a circuit breaker or fuse box. 4. Install a 5 amp (115 volt line voltage) or 3 amp (230 volt line voltage) fuse or circuit breaker in the line voltage spur. Be sure to place a label on the circuit breaker indicating the Universal LINC power shut-off point. 5. Plug the line voltage cable into the receptacle on the 5 VDC Power Supply. The plug is keyed for correct orientation. 6. Either plug the line voltage cable into a standard receptacle (such as is used in the UDC) or attach each conductor to the fuse or circuit breaker according to regulations. Wire Connections The Universal LINC232 has two ports. The LAN port is for connection directly to the network as a node or to a controller as an external device. The LAN port utilizes the RS485 standard. The RS232 port is for connection to serial devices using the RS232 standard. RS232 Connection The RS232 standard requires a 3-core shielded cable for transferring data. However, not all serial devices transmit data in the same manner. In particular, printers use the CTS pin. Also, there are two types of connector; a 9-pin and 25-pin. NOTE: The old style Universal LINC232 requires the DIP switch settings to match the type of device and connector type to communicate with a serial device. To properly connect the cable to the RS232 port, refer to the figure titled “Typical RS232 Wire Connections.” Determine the type of device and connector style and attach the appropriate wires. Be sure to attach the shield/screen to the GND terminal. LAN Connection The RS485 standard uses a twisted-pair, shielded cable to transfer data. A 5 volt DC signal is used as the signal and, if located within 39 in. (1 m) of a controller (signal generator), can be used to power the Universal LINC. An optional patch cable (Part No. 371-01429-000) is available to simplify connection to the LAN. (This cable is included with the Universal LINC232 Commissioning.) This patch cable allows quick connection to the LAN when using newer controllers, such as the TDCE, IDC and UDC. To connect the patch cable to the USB-style socket on the controller, simply insert the USB-style plug into the socket on the controller. At the Universal LINC end, remove the standard screw terminal connector and attach the patch cable. The patch cable is prewired to simplify connection. The figure titled “Typical RS485 LAN Connections” provides shows the different methods for connecting the LAN. Note the different methods for connecting YORK INTERNATIONAL 19 3 INSTALLATION FORM 450.20-N17 (702) the GND and 5VDC terminals. Power is always connected to the LAN side. When making RS485 connections, the cable shield (screen) should be connected at one end to a ground and left open (unconnected) at the other. Ideally, the shield continues as close as possible to the device unless the device is inside an enclosure. The Universal LINC232 provides a terminal for this purpose labelled SCREEN. Inside an enclosure, the shield should be connected to a ground point as soon as possible after the cable enters the enclosure. In this case, do not use the SCREEN (or USHL if connecting to a controller) terminal but connect to the closest ground/earth point. Switch Settings In order to provide the most flexibility with the least amount of effort required, the Universal LINC232 uses a set of DIP switches to configure the device. As the DIP switches are positioned, the software makes adjustments to ensure proper operation for the selected functions. The Universal LINC232 (Board No. MR022) and Universal LINC232 UCS (Part No. 371-03785-001 or 371-03876-001) differ in the terminology used for the switch settings, particularly regarding parity. With the Universal LINC232, the parity settings were based on a particular device and therefore labelled by device type. For the Universal LINC232 UCS, the parity settings are selectable by the user and not tied specifically to a device. In addition, the transfer rates were also increased to more accurately reflect typical baud rates. There are 12 DIP switches on the Universal LINC232. They are categorized by Parity or Device Type, Device Baud Rate, Node Address, and Communication Rate. Parity or Device Type The parity can be selected to accommodate virtually any device that communicates on an RS232 protocol. To determine specifically what the setting should be for each device, consult the documentation for that device. There are some typical settings which can be used in lieu of documentation. The original Universal LINC232 used these typical settings without specifically calling out the parity settings. Most devices allow the parity to be set as desired. The Universal LINC232 UCS allows the parity to be set to match the device instead of forcing the device to be adjusted to the Universal LINC. The following table shows recommended settings for various YORK products. These can, however be modified as desired. Table 2 – Recommended Parity Settings Device Recommended Parity Modem NONE Terminal NONE Facility Manager ODD IcE NONE YES* ODD * The Parity is not configurable in YES 9-Pin Device Printer Cable 25-Pin Device 19 7 3 9-Pin Device 7 2 3 Modem/Terminal Cable 5 2 3 Facility Manager/YES/IcE Cable CTS GND TX RX CTS GND TX RX CTS GND TX RX Figure 7. Typical RS232 Wire Connections 20 YORK INTERNATIONAL INSTALLATION FORM 450.20-N17 (702) NOTE: The position of the Parity switches are only checked when the Universal LINC232 is booted up. Any changes will not take effect unless power is reapplied. Select the appropriate switch setting for the specific device using the P1 and P2 (or S1 and S2) switches. When the device type is changed, the STATUS LED flashes once to indicate the change. NOTE: The Modem capability is for dial-in access to the network. For dialout capability, a LINC Guardian Modem device is required. The wiring must be connected as shown in the figure titled “RS232 Wire Connections” for the Universal LINC232 to communicate properly. The connector styles vary with each device but typically use the following connector style: Printer – DB-25 Connector Modem – DB-9 Connector VT100 Terminal – DB-9 Connector 3 Facility Manager/YES/IcE – DB-9 Connector Shield (Open) T EX N DE TO NO STATUS Shield (Open) Controller NODE SWITCH S1 Any ISN Controller w/ 5 VDC Power Supply 5 VDC GND P2 P3 USHL SCREEN P3 TX P2 GND RX 5VDC MODE 1 2 4 8 16 32 64 CS LAN IN OFF ON LAN PORT Red Black LINC Power Supply Shield (Open) T EX N DE TO NO T EX N DE O T NO STATUS Shield (Open) Controller NODE SWITCH S1 New Controller Equipped with USB-style Connector w/ 5 VDC from LAN 5 VDC GND P2 P3 USHL SCREEN P3 TX P2 GND RX 5VDC MODE 1 2 4 8 16 32 64 CS LAN IN OFF ON LAN PORT T EX N DE TO NO STATUS Controller NODE SWITCH S1 New Controller Equipped with USB-style Connector using Patch Cable SCREEN P3 TX P2 GND RX 5VDC MODE 1 2 4 8 16 32 64 CS OFF ON LAN IN LINC TO NEXT NODE TO NEXT NODE 5 VDC GND P2 P3 USHL LAN PORT Shield (Open) Figure 8. Typical RS485 LAN Connections YORK INTERNATIONAL 21 INSTALLATION FORM 450.20-N17 (702) Universal LINC232 UCS Network Status LEDs Red LED (TX) ON – LINC is transferring data. Green LED (RX) ON – LINC is receiving data. Status LED (Red) DOUBLE FLASH Unit OK OFF Unit failure or loss or power UNIVERSAL LINC232 UCS RS232 Device Connection STATUS Network Connection OFF ON CTS GND TX RX TX RX P1 P2 OFF OFF ON OFF OFF ON ON ON PARITY NONE SPACE ODD EVEN B1 B2 OFF OFF ON OFF OFF ON BAUD 4800 9600 19K2 CS OFF 19K2 LAN CS ON 50K LAN RS232 P1 P2 B1 B2 1 2 4 8 16 32 64 CS SCREEN P3 TX P2 GND RX 5VDC LAN RS232 Device Status LEDs Red LED (TX) ON – LINC is transferring data. Green LED (RX) ON – LINC is receiving data. DIP Switches Status LED (Red) ON Unit OK OFF Unit failure or loss or power CONTINUOUS FLASH – Node address set to zero (0). Universal LINC232 (Original) Note: A single flash indicates the device settings are reset. UNIVERSAL LINC232 CTS GND TX RX TX RX RS232 PORT 2 S1 S2 OFF OFF ON OFF OFF ON ON ON LINC PRINTER FM MODEM TERMINAL B1 B2 BAUD OFF OFF 1200 ON OFF 2400 OFF ON 4800 ON ON 9600 CS OFF 19K2 LAN CS ON 50K LAN STATUS OFF ON S1 S2 B1 B2 1 2 4 8 16 32 64 CS SCREEN P3 TX P2 GND RX 5VDC LAN PORT 1 Figure 9. Universal LINC232 Components 22 YORK INTERNATIONAL INSTALLATION FORM 450.20-N17 (702) Device Baud Rate Communication Switch The transfer rate of the devices which can be connected to the Universal LINC232 vary. To select the appropriate transfer rate, use switches B1 and B2. Four transfer rates are available, from 1200 to 9600 baud, for the original Universal LINC232 and three rates are available, from 4800 to 19,200 (19k2) baud, for the current, UCS variant. The Communication Switch (CS) sets the Universal LINC232 to communicate at the network transfer speed. This can be either 19.2 or 50 kbaud. Set switch CS to OFF to operate at 19.2 kbaud and ON to operate at 50 kbaud. NOTE: If connecting to an existing network using Rev. 76 software or earlier, LAN transfer rates are limited to 19.2 kbaud. For new installations, Rev. 77, and UCS software, the transfer rate should be set to 50 kbaud. Node Address Each device on an ISN network must have a unique identifier or node address. This node address can be any number between 1 and 98. Switches 1 through 64 are used to set the node address. These are binary switches which, when summed, add up to the node address. The CS switch position is only examined when the device is first powered up. Any changes made to the CS switch are ignored unless power is removed and re-applied. Device Transfer Rate (UCS) B1 OFF ON OFF ON B2 OFF OFF ON ON Baud Rate 4800 9600 19,200 Not Used Device Transfer Rate (Original) B1 OFF ON OFF ON B2 OFF OFF ON ON Baud Rate 1200 2400 4800 9600 LAN Transfer Rate CS OFF ON Parity (UCS) Switch Settings P1 P2 B1 B2 1 2 4 8 16 32 64 CS P1 P2 B1 B2 1 2 4 8 16 32 64 CS Parity or Device Type (S1) Parity or Device Type (S2) Device Transfer Rate Device Transfer Rate Node Address Node Address Node Address Node Address Node Address Node Address Node Address LAN Transfer Rate OFF ON 19.2 kbaud 50 kbaud NOTE: Baud rate selection is only read at power up of the unit. Any changes during operation will not take effect until next power up. P1 OFF ON OFF ON P2 OFF OFF ON ON Parity None Space Odd Even Device Type (Original) S1 OFF ON OFF ON S2 OFF OFF ON ON Device Printer Facility Manager/YES Modem Terminal Node Address Set the node DIP switches to a unique valid address between 1 and 92. Sum the values of each switch in the ON position to determine the address setting, i.e., 1 + 4 + 64 = 77 Figure 10. Universal LINC232 DIP Switch Positions YORK INTERNATIONAL 23 3 INSTALLATION FORM 450.20-N17 (702) Continuity and Isolation Checks CAUTION: Always check for isolation and continuity before applying power to a network. A common cause of failure of network devices is incorrect wiring. Incorrect wiring typically causes short circuits along the network wiring resulting in defective RS485 transceivers. Other possible symptoms of faulty wiring are open circuits and the presence of voltage collected by the shielding. devices on the network. With the LAN connectors removed from any devices: 1. Check for open circuits on the P2 and P3 conductors. Resistance should be low between the ends of each conductor. If not, check for breaks in the wire. 2. Check for short circuits by observing resistance between the P2 and P3 conductors, P2 and ground/earth, and P3 and ground/earth. The presence of a resistance other than infinity indicates a break in the wire. To ensure proper wiring there are several checks that should be completed before applying power to any 24 YORK INTERNATIONAL MAINTENANCE FORM 450.20-N17 (702) SECTION 4 MAINTENANCE LEDs Port LEDs The Universal LINCs are equipped with LEDs to aid in troubleshooting operation and communications. Each port has two Comms LEDs to signify the module is receiving (RX) or transmitting (TX) data. The RX LED is green and the TX LED is red. Status LED A red Status LED indicates operating condition. The Universal LINC232 UCS follows the UCS LED conventions for flash rates. The TX LED indicates that the Universal LINC232 is transferring data. Likewise, the RX LED indicates data is being received by the Universal LINC232. This applies to either port. FLASHING – Normal operation of the Universal LINC232. Since there is no “configured” software, the Universal LINC232 indicates that the software is not configured but it functions properly. (For a controller, the software must be configured.) 4 OFF – The device has failed or lost power. For the original Universal LINC232, there are three operational states for the Status LED. ON – The device is on and operating normally. FLASHING – The Node switch is set to 0, which is an invalid address. OFF – The device has failed or has lost power. NOTE: The Status LED flashes once whenever the device type is changed to indicate reset. YORK INTERNATIONAL 25 MAINTENANCE FORM 450.20-N17 (702) SYMPTOM Green LED for a single device is constantly ON. PROBABLE CAUSE Transceiver is damaged. SOLUTION Ensure LAN cable is wired correctly. Disconnect LAN cable with power ON. If light remains on, replace LINC. Network voltage levels exceeded. Measure voltage between P2 and P3. If greater than 5 VDC, isolate network devices and determine cause. Measure voltage between P2 and ground/earth and between P3 and ground/earth. If greater than 12 or less than -7 VDC, isolate networks devices and determine cause. Red and green LEDs for a single device are constantly ON. Transceiver is damaged. Disconnect LAN cable with power ON. If light remains on, replace LINC. Green LED on for all network devices. Multiple transceivers damaged. Disconnect LAN devices one at a time until fault indication disappears. Repair/replace faulty device. Short circuit between shield and P3. Remove power and disconnect the LAN cable at both ends. Ensure resistance between P3 and shield is infinite. If not, replace cable. Status LEDs are normal but units do Multiple transceivers damaged. not communicate. Disconnect LAN devices one at a time until fault indication disappears. Repair/replace faulty device. Short circuit between P2 and P3. Remove power and disconnect the LAN cable at both ends. Ensure resistance between P2 and P3 is infinite. If not, replace cable. Short circuit between shield and P2. Remove power and disconnect the LAN cable at both ends. Ensure resistance between P2 and shield is infinite. If not, replace cable. Network voltage levels exceeded. Measure voltage between P2 and P3. If greater than 5 VDC, isolate network devices and determine cause. Measure voltage between P2 and ground/earth and between P3 and ground/earth. If greater than 12 or less than -7 VDC, isolate networks devices and determine cause. 26 YORK INTERNATIONAL MAINTENANCE FORM 450.20-N17 (702) SYMPTOM Green LEDs dimly lit on all devices. PROBABLE CAUSE Electrical noise on the network. SOLUTION Disconnect LAN devices one at a time until fault indication disappears. Reroute LAN cable away from noise source (VSDs etc.). Polarity of P2 and P3 crossed in the Disconnect all LAN devices and LEDs occasionally are not operating network. check continuity. properly (stay ON). 4 YORK INTERNATIONAL 27 APPENDIX FORM 450.20-N17 (702) Universal LINC232 SPECIFICATIONS General Electrical Primary Power Source Frequency Power Consumption Storage Temperature Operating Environment Maximum Altitude Size (H x W x D) Size (H x W x D) Weight 5 VDC, (±5%) N/A Nominal 180 mA; Current limited to 250 mA -40 to 160° F (-40 to 70° C) 32 to 122° F (0 to 50° C) 10 to 95% RH non-Condensing 6500 ft. (2000 m) above sea level 3.93 x 2.75 x 2.17 in. (100 X 70 X 55 mm) on DIN rail 3.25 x 2.00 x 0.88 in. (83 X 51 X 22 mm) Pocket Version 0.44 lb. (0.20 kg) Processor Memory PROM Memory RAM NEC V25 Operating at 8 MHz 256 kbytes of CMOS EPROM 128 kbytes of CMOS RAM User Functions Port 1 Port 2 Terminations Status LEDs Switch Selections Network Cable RS485 LAN/USB Cable (19.2 or 50 kbaud) RS232 Device Port (4800, 9600 or 19,200 baud) Removable Terminal Strips. Max Cable Size 16 AWG (1.5 mm² CSA) System Status; LAN Status; Device (RS232) Status Device Type; Device Transfer Rate; Node Address (1-98); LAN Transfer Rate Twisted-Pair Shielded (Belden 9272 or Equivalent) Optional Power Supply Kit Power Frequency Power Consumption Maximum Power Output Size (H x W x D) Weight 115/230 VAC (±10%) 50/60 Hz (±10%) Nominally 2VA 300 mA 3.66 x 3.78 x 2.95 in. (93 X 96 X 75 mm) on DIN rail 1.1 lb. (0.5 kg) Optional USB Cable Cable Length 39 in. (1 m) Ordering Information Universal LINC232 UCS Universal LINC232COM UCS 5 VDC Power Supply 115 VAC Input 5 VDC Power Supply 230 VAC Input Patch Cable Small Enclosure with DIN Rail Agency 28 371-03785-001 371-03876-001 371-04130-001 371-04130-002 371-01429-000 371-04131-000 UL 916 Pending FCC Part 15 Conducted and Radiated LVD Standard EN60950 Emission Standard EN55022; 1994 Class A CE (Satisfying all the relevant EMC directives) and IEC950/EN60950 (Safety directive) YORK INTERNATIONAL APPENDIX FORM 450.20-N17 (702) YORK INTERNATIONAL 29 P.O. Box 1592, York, Pennsylvania USA 17405-1592 Tele. 800-861-1001 website: www.york.com Copyright © by York International Corporation 2002 Form 450.20-N17 (702) New Release Unit 1, Red Shute Hill, Hermitage, Newbury, Berks RG18 9QL United Kingdom Tele: +44 (0)1635 202200 e-mail: controls.sales@uk.york.com Subject to change without notice. Printed in USA ALL RIGHTS RESERVED