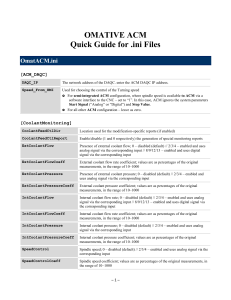

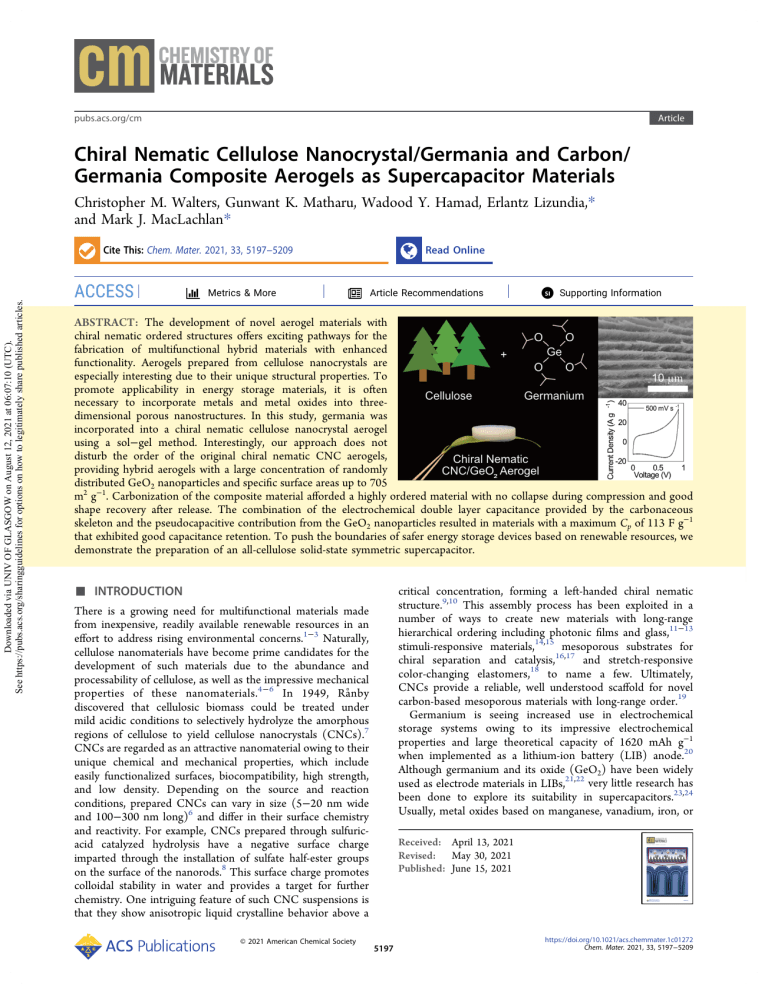

pubs.acs.org/cm Article Chiral Nematic Cellulose Nanocrystal/Germania and Carbon/ Germania Composite Aerogels as Supercapacitor Materials Christopher M. Walters, Gunwant K. Matharu, Wadood Y. Hamad, Erlantz Lizundia,* and Mark J. MacLachlan* Downloaded via UNIV OF GLASGOW on August 12, 2021 at 06:07:10 (UTC). See https://pubs.acs.org/sharingguidelines for options on how to legitimately share published articles. Cite This: Chem. Mater. 2021, 33, 5197−5209 ACCESS Metrics & More Read Online Article Recommendations sı Supporting Information * ABSTRACT: The development of novel aerogel materials with chiral nematic ordered structures offers exciting pathways for the fabrication of multifunctional hybrid materials with enhanced functionality. Aerogels prepared from cellulose nanocrystals are especially interesting due to their unique structural properties. To promote applicability in energy storage materials, it is often necessary to incorporate metals and metal oxides into threedimensional porous nanostructures. In this study, germania was incorporated into a chiral nematic cellulose nanocrystal aerogel using a sol−gel method. Interestingly, our approach does not disturb the order of the original chiral nematic CNC aerogels, providing hybrid aerogels with a large concentration of randomly distributed GeO2 nanoparticles and specific surface areas up to 705 m2 g−1. Carbonization of the composite material afforded a highly ordered material with no collapse during compression and good shape recovery after release. The combination of the electrochemical double layer capacitance provided by the carbonaceous skeleton and the pseudocapacitive contribution from the GeO2 nanoparticles resulted in materials with a maximum Cp of 113 F g−1 that exhibited good capacitance retention. To push the boundaries of safer energy storage devices based on renewable resources, we demonstrate the preparation of an all-cellulose solid-state symmetric supercapacitor. ■ INTRODUCTION There is a growing need for multifunctional materials made from inexpensive, readily available renewable resources in an effort to address rising environmental concerns.1−3 Naturally, cellulose nanomaterials have become prime candidates for the development of such materials due to the abundance and processability of cellulose, as well as the impressive mechanical properties of these nanomaterials.4−6 In 1949, Rånby discovered that cellulosic biomass could be treated under mild acidic conditions to selectively hydrolyze the amorphous regions of cellulose to yield cellulose nanocrystals (CNCs).7 CNCs are regarded as an attractive nanomaterial owing to their unique chemical and mechanical properties, which include easily functionalized surfaces, biocompatibility, high strength, and low density. Depending on the source and reaction conditions, prepared CNCs can vary in size (5−20 nm wide and 100−300 nm long)6 and differ in their surface chemistry and reactivity. For example, CNCs prepared through sulfuricacid catalyzed hydrolysis have a negative surface charge imparted through the installation of sulfate half-ester groups on the surface of the nanorods.8 This surface charge promotes colloidal stability in water and provides a target for further chemistry. One intriguing feature of such CNC suspensions is that they show anisotropic liquid crystalline behavior above a © 2021 American Chemical Society critical concentration, forming a left-handed chiral nematic structure.9,10 This assembly process has been exploited in a number of ways to create new materials with long-range hierarchical ordering including photonic films and glass,11−13 stimuli-responsive materials,14,15 mesoporous substrates for chiral separation and catalysis,16,17 and stretch-responsive color-changing elastomers,18 to name a few. Ultimately, CNCs provide a reliable, well understood scaffold for novel carbon-based mesoporous materials with long-range order.19 Germanium is seeing increased use in electrochemical storage systems owing to its impressive electrochemical properties and large theoretical capacity of 1620 mAh g−1 when implemented as a lithium-ion battery (LIB) anode.20 Although germanium and its oxide (GeO2) have been widely used as electrode materials in LIBs,21,22 very little research has been done to explore its suitability in supercapacitors.23,24 Usually, metal oxides based on manganese, vanadium, iron, or Received: April 13, 2021 Revised: May 30, 2021 Published: June 15, 2021 5197 https://doi.org/10.1021/acs.chemmater.1c01272 Chem. Mater. 2021, 33, 5197−5209 Chemistry of Materials pubs.acs.org/cm Article Table 1. Comparison of CNC/GeO2 Alcogel Formulations and Time Taken for the Prepared Sols to Gel sample CNC solution [g] DMF [g] H2O:DMFa TPOG [μL] TPOG [mmol] gelation timeb [days] CNC/GeO2-50 CNC/GeO2-100 CNC/GeO2-200 CNC/GeO2-300 2 2 2 2 4.3 4.1 3.8 3.6 5:95 10:90 15:85 20:80 50 100 200 300 0.17 0.33 0.67 1.0 no gelation after 5 days no gelation after 5 days 4, soft gel 3, firm gel a Ratio of H2O:DMF used relative to the amount of TPOG added to 2 g of phase-separated anisotropic aqueous CNCs. bGelation time refers to the minimum time required to form a viscous sol. study provides a possible route toward incorporating germanium into well ordered carbonaceous materials for energy storage applications. Our group has recently shown the potential of mesoporous chiral nematic structures derived from CNCs to function as long-life cycle rechargeable lithium-ion battery anodes,46 where the architecture originating from CNCs provides a robust physical framework able to accommodate the volume changes occurring during successive Li+ insertion/extraction processes (or charging/discharging). On this basis, we decided to explore the versatility of mesoporous chiral nematic aerogels derived from CNCs as supercapacitor materials so the functionality of CNC-based chiral nematic structures as electrochemical energy storage systems is better understood. Here, we report the synthesis of mesoporous CNC/GeO2 composite aerogels exhibiting long-range chiral nematic order with a high surface area. By carefully controlling the hydrolysis and condensation of the germanium alkoxide precursor, we were able to grow germania nanoparticles (86 ± 22 nm) inside a cellulose matrix without aggregation and obtain composite aerogels. Further carbonization of the composite materials afforded carbon/GeO2 aerogels that retained their original chirality and high surface area. Mechanical and liquid electrolyte uptake studies demonstrate the benefit of having the germania embedded in a well-ordered carbon support, while cyclic voltammetry studies suggest these materials perform well when used as electrodes in symmetric supercapacitor cells. As an added outlook to the future, and to the best of our knowledge, we prepare the first solid-state symmetric supercapacitor based entirely on cellulose. Overall, this work demonstrates a synthetic route that can potentially be applied to other water-sensitive inorganic precursors, expanding the horizons for other cellulose/metal oxide-based aerogel materials for use in energy storage. cobalt, for example, are preferred due to their reversible electrochemical redox processes, despite good evidence that other group IV oxides may be useful.25,26 For example, tin oxide/graphene nanocomposites have shown a maximum specific capacitance of 818 F g−1,25 and like germanium oxide, tin oxide is a wide bandgap n-type semiconductor.27 Although to the best of our knowledge no precedent on the use of germanium oxide supercapacitors exists, related materials such as Zn2GeO4 have been proven to show reversible faradic redox reactions when applied as supercapacitor electrodes.28 Likely, the redox pseudocapacitance of GeO2 is generally considered unattractive in comparison with transition metal oxides;29 however, we hypothesize that the semiconductor characteristics of GeO2 can help to overcome the constraints seen in many metal oxides, where the poor electrical conductivity limits the contribution of the bulk material to the total capacitance (mostly surface contributions through reversible redox reactions occur).30−33 Additionally, GeO2 has a relatively high dielectric permittivity, and this property has been previously shown to enhance the energy storage capacity of barium titanate-based supercapacitors.34,35 With respect to its mechanical properties, GeO2 is structurally flexible and has an increased resistance against volume expansion/shrinkage upon charge/discharge processes, which gradually deteriorate the electrochemical performance of energy storage devices.21,22 Enlarging the active surface area by anchoring GeO2 nanoparticles (NPs) into a mesoporous carbon support will shorten the ion diffusion path and enhance the available area to interact with the electrolyte, further boosting the energy storage ability.36,37 For these reasons, it would be interesting to explore the applicability of carbonsupported GeO2 in supercapacitors. Aerogels are perfect candidates for supercapacitors since they are low-density, lightweight materials with a high porosity and surface area.38,39 Although monolithic germania aerogels have been reported, these materials have a relatively low surface area (155 m2 g−1) and lack long-range order.40 Moreover, because it has been repeatedly shown that Ge/ carbon or GeO2/carbon based electrode materials perform better than their monolithic counterparts, it is of interest to incorporate a carbon support, such as an organic polymer or CNCs for enhanced electrode performance.22,41,42 Despite this, there are few reports on the preparation of such materials.43,44 One possible reason for this is that commonly used germanium alkoxide precursors such as tetraethoxygermane (TEOG) or tetraisopropoxygermane (TPOG) undergo rapid hydrolysis and condensation, limiting successful incorporation into mesoporous ordered frameworks.40 In 2018, Xu et al. reported a sol−gel method for incorporating siloxanes into CNC suspensions to yield the corresponding chiral nematic CNC/ silica aerogels with surface areas exceeding 700 m2 g−1.45 Although the siloxanes used in that study hydrolyze and condense much slower than their germanium analogues, the ■ EXPERIMENTAL SECTION Materials. All chemicals were used as received without further purification. Aqueous CNC suspensions (4.0 wt %, pH ∼ 2.5) were supplied by FPInnovations, prepared according to a previously published procedure.13 N,N-Dimethylformamide (DMF) (HPLC grade), tetraisopropoxygermane (TPOG) (97%), carboxymethyl cellulose (CMC) with a Mw of 250 000 g mol−1 and a degree of substitution of 1.2, sodium sulfate (Na2SO4) (ACS reagent, ≥99.0%), citric acid (ACS reagent, ≥99.5%), and hydrochloric acid (HCl) (ACS reagent, 37%) were purchased from Sigma-Aldrich. Synthesis of CNC Aerogels with Periodic Structure (CNCControl). Following a procedure similar to that of Xu et al.,45 an aqueous CNC suspension (4 wt %, 15 mL) was allowed to phase separate in a capped vial at room temperature for 96 h. A portion of the lower anisotropic phase (2 g) was removed by syringe and transferred into a 20 mL scintillation vial, which was sealed and stored in a refrigerator (4 °C) for 48 h to allow the CNCs to reassemble. Cold ethanol (16 mL, 100%, 4 °C) was slowly layered on top of the suspension to avoid disrupting the CNCs, and the vial was subsequently sealed and stored in a refrigerator. After 24 h, half of 5198 https://doi.org/10.1021/acs.chemmater.1c01272 Chem. Mater. 2021, 33, 5197−5209 Chemistry of Materials pubs.acs.org/cm the ethanol was removed by a syringe and carefully replaced with fresh cold ethanol (4 °C). This step was repeated for a total of 7 days. To avoid swelling of the gel, HCl (30 μL, 0.12 M) was added to the vial on days 2−4. The resultant alcogel was clear and was carefully removed from the vial by scoring and breaking the vial base. The alcogel was stored in pure ethanol and immediately dried by supercritical drying. Synthesis of CNC/GeO2 Aerogels with Periodic Structure (CNC/GeO2). The phase-separated anisotropic aqueous solution of CNCs (2 g) was transferred into a 20 mL scintillation vial to which DMF was slowly added (Table 1). The suspension was swirled until uniform and was subjected to rotary evaporation (25 mbar, 30 °C) to remove water until the mass of the CNC solution returned to 2 g. Once the appropriate ratio was achieved, the vial was sonicated in a bath sonicator to release accumulated CNCs from the wall of the vial and then allowed to rest for 1 h. The vial containing the CNC suspension was then stirred at 700 rpm, and TPOG stored under N2 was added via a glass syringe. The solution was stirred for 15 min and occasionally agitated to dissolve any white globular precipitate that formed. The clear, colorless sol was stored in the refrigerator (4 °C) for 72 h to allow reorganization of the CNCs. As before, cold ethanol (16 mL, 100%, 4 °C) was slowly layered on top of the sol to prevent agitation and then sealed and stored in the fridge. After each 24 h period, half the ethanol was removed via syringe and replaced with fresh cold ethanol. This step was repeated for a total of 7 days. The resultant alcogels were translucent, but their opacity increased with increasing TPOG concentration. The alcogel was stored in pure ethanol and immediately dried by supercritical drying. Supercritical CO2 (sc-CO2) Drying of Alcogels. Alcogels were dried using a Tousimis Autosamdri 815B Critical Point Dryer. Samples were purged for 5 min and at the beginning of the heating stage the instrument was turned off for a 1.5 h stasis step. This process was repeated 2 additional times prior to heating to the supercritical point. The resultant aerogels were transparent after drying but turned opaque after a few days of storage under ambient conditions (Figure S1). This is likely due to index matching of water in the pores as water is adsorbed from the atmosphere. Carbonization of Aerogels (C/GeO2). The aerogels were affixed between two glass slides and secured with a metal wire before being placed into a XST-3-0-18-1C tube furnace (Thermcraft, Inc.) with a 2404 temperature controller (Eurotherm, Thermcraft, Inc.). Prior to heating, the atmosphere was purged with Ar for 10 min. All aerogels were heated under a constant flow of argon gas using the following program: ramp (25−100 °C, 2 °C min−1), hold (100 °C for 60 min), ramp (100−200 °C, 2 °C min−1), hold (200 °C for 60 min), ramp (200−250 °C, 2 °C min−1), hold (250 °C for 7 h), cooling to RT (under an Ar atmosphere). Characterization. Scanning Electron Microscopy (SEM). Micrographs in Figure 2B,F were obtained from a S4700 field emission scanning electron microscope (Hitachi). Samples were prepared by breaking the aerogel and placing it onto double-sided carbon adhesive tape loaded onto an aluminum stub. The samples were sputter-coated with 4 nm of platinum/palladium (80/20). Samples were measured at a working distance of 5 mm with an accelerating voltage of 5 kV and a filament current of 10 μA. Micrographs in Figure 2A,D,E,H were obtained from a S-3400N scanning electron microscope (Hitachi) following a similar sample preparation method. The samples were sputter-coated with 10 nm of gold. Samples were measured at an acceleration voltage of 15 kV, a working distance of 7−9 cm, and a filament current of 9.4−10.9 μA. Focused Ion Beam (FIB) SEM. Micrographs in Figure 2C,G were obtained from a Crossbeam 550 (Carl Zeiss) FIB-SEM. No sputtercoating was done due to the risk of sample modification. Instead, a cascade of FIB induced carbon depositions was done starting with low current (10 pA, 50 pA, 100 pA, and finally 300 pA). The pad size was 20 × 10 μm. The probe voltage and current were 30 kV and 300 pA, respectively, with a milling dose of 400 mC. For serial sectioning and imaging, the FIB slice thickness was 25 nm. The nanoparticle size was analyzed using ImageJ. To ensure an accurate nanoparticle size was estimated, we measured the size of nanoparticles from two separate Article images taken at different depths during milling. In each image, 300 nanoparticles were measured as shown in Figure S2. Powder X-ray Diffraction (PXRD). PXRD patterns were recorded on a D8 Advance (Bruker) diffractometer equipped with a Cu Kα sealed tube X-ray source and a NaI scintillation detector. Samples were mounted onto a zero-background silica plate and secured using double-sided tape. Polarized Optical Microscopy (POM). Images were collected on an Olympus BX41 (Olympus Corp.) optical microscope by removing the alcogels from an ethanol solution and placing them on a glass slide. Ethanol was periodically added to the specimen during imaging to prevent dehydration. Thermogravimetric Analysis (TGA). TGA was performed on a TG 209 F1 Libra (Netzsch) thermogravimetric analyzer. Samples were heated from 25 to 800 °C at 10 °C min−1 under air (oxidative atmosphere). Nitrogen Sorption (N2 sorption). N2 sorption isotherms were collected at 77 K on an accelerated surface area and porosimetry (ASAP) 2020 analyzer (Micromeritics). Prior to analysis, aerogel samples (50 mg) were degassed at 120 °C for 8 h under the following conditions: evacuation phase (10 °C min−1, 120 °C, 4 h), heating phase (10 °C min−1, 120 °C, 4 h). Nitrogen sorption isotherms were collected and evaluated using Brunauer−Emmett−Teller (BET) and Barrett−Joyner−Halenda (BJH) methods for surface area and pore size analysis, respectively. Mechanical Tests. Properties of the aerogels were evaluated in compression mode on an AGS-X universal testing machine (Shimadzu) equipped with a 500 N load cell in displacement control mode at a rate of 0.5 mm min−1. Cylinder-shaped 3.5 ± 0.5 mm thick aerogels with ⌀ = 15 ± 1 mm were used. The tests were performed on either dry aerogels or wet aerogels soaked in an aqueous solution of Na2SO4 (1 M) for 24 h. The compressive modulus was calculated from the linear region in the compressive stress−strain curves. Ultraviolet−Visible (UV−Vis) Spectroscopy. Measurements were performed with a Cary 60 UV−vis double beam spectrophotometer (Agilent). Absorbance values within the 200−800 nm range were obtained using a sampling interval of 1 nm at 200 nm min−1. Approximately 100 mg of CNC-based aerogels or ca. 45 mg of carbon-based aerogels were soaked in 5 mL of 1 M Na2SO4 for 24 h and then removed before measuring the supernatant. Raman Spectroscopy. Measurements were performed on a Senterra II Raman microscope (Bruker). Data were collected using a 532 nm laser at 12.5 mW, with a 5 s integration time. A 20× objective aperture was used to focus the laser onto the sample. The spectral baseline was fit to an exponential decay, and the curves were deconvoluted using a Lorentz fit to extract the peak intensity of the D and G bands of the carbonized aerogels, as done in the literature.47 Electrochemical Measurements. The supercapacitor behavior of the aerogels was investigated using cyclic voltammetry (CV) experiments in a Swagelok two-electrode cell with stainless-steel current collectors with a VMP3 potentiostat (Bio-Logic Science Instruments). Symmetric supercapacitor cells were fabricated using two aerogels of the same formulation (⌀ = 8 mm) separated by a mesoporous CNC membrane (⌀ = 10 mm) soaked in an aqueous Na2SO4 solution (1 M) for 24 h. The mesoporous CNC membrane was fabricated through evaporation-induced self-assembly (EISA) according to Lizundia et al.48 CV data were collected at scan rates between 10 and 500 mV s−1 in the 0−0.9 V potential range. The specific capacitance (Cp, F g−1) was calculated from eq 1 Cp = ∫ I dV f ΔVm (1) where I represents the current intensity (A), f accounts for the scan rate (V s−1), ΔV is the potential window (V), and m is the aerogel mass (g). For solid-state symmetric supercapacitors, a cellulosic-gel was used as both the separator and the electrolyte. Carboxymethyl cellulose (1 g) was dissolved into Na2SO4 (50 mL, 1 M) with continuous stirring until the solution became clear (6 h). Citric acid (0.2 g) was added to 5199 https://doi.org/10.1021/acs.chemmater.1c01272 Chem. Mater. 2021, 33, 5197−5209 Chemistry of Materials pubs.acs.org/cm Article Scheme 1. Formation of the CNC/GeO2 Aerogel Using the Combined Method of CNC Self-Assembly and Sol−Gel Chemistrya a (A) An aqueous suspension of 4 wt % CNCs is added to a vial and allowed to sit until (B) the CNCs phase separate into anisotropic (lower) and isotropic (upper) layers. The isotropic phase is discarded, and (C) the appropriate ratio of H2O:DMF is obtained through rotary evaporation after which (D) TPOG is added to the vial and mixed. Over the course of 3 days, TPOG undergoes hydrolysis and condensation to form GeO2 nanoparticles. Next, the solvent is replaced with ethanol, and the resultant alcogel is sc-CO2 dried to yield the resultant (E) CNC/GeO2 aerogel, which shows a homogenous distribution of GeO2 throughout the chiral nematic cellulose structure. Figure 1. (A) POM images of prepared CNC-Control, CNC/GeO2-100, and CNC/GeO2-300 alcogels demonstrating characteristic chiral nematic fingerprint regions. Scale bar is 5 μm. Photographs showing the macroscopic appeareance of (B) CNC-Control (I), CNC/GeO2-50 (II), CNC/ GeO2-100 (III), CNC/GeO2-200 (IV), and CNC/GeO2-300 (V) alcogels. Photographs were taken of the alcogel in a Petri dish over top of the UBC text (white) on a black background to illustrate the difference in opacity of the samples. (C) CNC/GeO2-300 aerogel and (D) C/GeO2-300 aerogel. The scale bar for (B), (C), and (D) is 2.5 cm. the solution, and the aerogels were soaked in the Na2SO4−CMC gel electrolyte for 60 min, picked out, and finally treated at 80 °C for different times to allow gel formation through double esterification cross-linking.49 Finally, aerogels were assembled facing each other in an all-solid-state flexible supercapacitor using a Swagelok twoelectrode cell. the anisotropic layer could be captured through a sol−gel method to yield neat cellulose or cellulose/silica aerogels. Importantly, the CNCs needed time undisturbed to reorganize into a chiral structure prior to gelation; otherwise, the resultant aerogel would lack structural ordering.45 In water, tetraisopropoxygermane (TPOG) undergoes the following hydrolysis (eq 2) and condensation (eqs 3 and 4) processes: ■ RESULTS AND DISCUSSION Synthesis. Chiral nematic CNC/GeO2 aerogels were prepared using a sol−gel method that gave a homogeneous distribution of germania nanoparticles (NPs) in an ordered chiral nematic CNC network; the preparation route is shown in Scheme 1. When left to stand, aqueous suspensions of CNCs will phase-separate into isotropic (upper) and anisotropic (lower) phases over the course of a few days, where the lower phase of the CNCs has a chiral nematic organization.10,45 Xu et al. demonstrated that the chirality of Hydrolysis: Ge(Oi Pr)4 + H 2O F Ge(OH)(Oi Pr)3 + i PrOH (2) Condensation: Ge(OH)(Oi Pr)3 + GeOH(Oi Pr)3 F (Oi Pr)3 GeOGe(Oi Pr)3 + H 2O 5200 (3) https://doi.org/10.1021/acs.chemmater.1c01272 Chem. Mater. 2021, 33, 5197−5209 Chemistry of Materials pubs.acs.org/cm Article Table 2. Brunauer−Emmett−Teller (BET) Surface Area, Barrett−Joyner−Halenda (BJH) Pore Size and Volume, and Calculated Density and Porosity for the Prepared Aerogel Materials sample CNC-Control Carbon-Control CNC/GeO2-50 C/GeO2-50 CNC/GeO2-100 C/GeO2-100 CNC/GeO2-200 C/GeO2-200 CNC/GeO2-300 C/GeO2-300 surface area [m2 g−1] pore size [nm] pore volume [cm3 g−1] 225 518 217 599 211 656 260 705 236 695 14.8 16.5 11.7 15.1 13.7 10.8 11.3 9.6 8.8 10.9 0.80 1.59 0.63 1.61 0.72 1.23 0.72 1.07 0.52 1.30 porosity [%] shrinkage after carbonization [%] 0.07 0.09 0.07 0.11 0.06 0.10 0.06 0.13 0.50 0.09 95.2 93.7 95.8 92.9 94.0 94.6 96.8 95.1 97.6 97.0 87 N/A 86 N/A 80 N/A 76 N/A 77 N/A The alcogel was converted into an aerogel by supercritical CO2 drying to give a dried product that maintained the pore characteristics of the original alcogel (Figure 1C). Supercritical drying was used instead of freeze drying to prevent damaging the porous macrostructure, which would have resulted in pore collapse.51 In this work, the aerogels were cylindrical because the alcogels were prepared in a cylindrical vial. To afford a material suitable for use in energy storage applications,22,41,42 the aerogels were carbonized (Figure 1D) under a flow of argon while secured between two glass slides to prevent them from curling during heating. When temperatures exceeded 300 °C, the samples shrunk more than 75% and became too brittle to handle. For this reason, carbonization was performed at 250 °C. PXRD patterns of the aerogels pre- and postcarbonization (CNC/GeO2 and C/GeO2, respectively) are shown in Figure S4. In general, there is an increase in intensity of the germania peaks (PDF: 00-036-1463)52 with TPOG loading. We estimated the size of the crystallites using the Scherrer equation53 after deconvoluting the diffraction peak corresponding to the (101) plane (Figure S5) and found them to be ca. 15 nm prior to carbonization and ca. 25 nm after carbonization. There is likely annealing and fusion of crystalline domains at elevated temperature.54 PXRD analysis of the CNC/GeO2 aerogels also showed diagnostic peaks for cellulose at ∼18° and ∼22° 2θ, which disappeared following carbonization. The carbonized samples instead showed a broad peak between ∼17 and 27° 2θ that is diagnostic of partially graphitized carbon. This is in contrast to other works where crystalline graphitic materials were obtained when CNCs were carbonized at temperatures exceeding 400 °C.55,56 Further characterization by Raman spectroscopy (Figure S6) shows the presence of broad D (ca. 1364 cm−1) and G (ca. 1581 cm−1) bands with a D/G ratio of 0.78, that, when combined with the lack of a strong diffraction peak at (002), suggests the material is largely amorphous and lacks graphitic structure. The surface area and porosity of the composite aerogels were determined with nitrogen adsorption/desorption isotherms. N2 gas sorption isotherms for all aerogels indicated a type IV isotherm with an H2 hysteresis loop consistent with mesoporous materials with cylindrical and spherical pores (Figure S7).57 The surface areas, pore sizes, pore volumes, and porosity of the prepared aerogels are reported in Table 2. In general, the cellulosic aerogels have surface areas between 220 and 260 m2 g−1 and pore sizes and volumes of 9−15 nm and 0.5−0.8 cm3 g−1, respectively. The total pore volume (VT) (Table S1, Equation S1, and Equation S2) calculated based on Ge(OH)(Oi Pr)3 + Ge(Oi Pr)4 F (Oi Pr)3 GeOGe(Oi Pr)3 + i PrOH apparent density [g cm3] (4) This process occurred very rapidly when TPOG was added directly to aqueous CNC suspensions, forming germania aggregates that precipitated. Our challenge for the synthesis of these aerogels was to find conditions that enabled control over the hydrolysis and condensation while simultaneously maintaining the colloidal stability of the system. Diluting the aqueous CNC suspension with DMFa well-known drying control chemical additive for sol−gel processes50could lower the reactivity of TPOG; however, there is a trade off in CNC stability. Therefore, ratios of H2O:DMF were judiciously chosen relative to the concentration of the germanium precursor to delay the onset of gelation until at least 72 h after mixing to achieve a chiral structure. Table 1 lists the gelation time observed after TPOG addition to suspensions of CNCs in different H2O:DMF ratios. To illustrate the importance of these ratios, PXRD patterns of CNC/GeO2-300 prepared from different ratios of H2O:DMF are shown in Figure S3. At low ratios of water, the germania in the resultant aerogel was amorphous, but the sol gelled so quickly that the aerogel had no structural ordering. At high concentrations of water, the germania in the aerogel is highly crystalline, but the resultant sol and aerogel contained visible aggregates. In this study, we focused on preparing aerogels that maintained chiral nematic order while hosting a homogeneous distribution of the germania NPs. Suitable H2O:DMF ratios for TPOG exceeding 1 mM were not found, and all H2O:DMF ratios led to gelation and precipitation within minutes of adding the TPOG. As tetraethoxygermane (TEOG) condensed far too quickly, our study only pertains to aerogels prepared from TPOG. The prepared CNC/TPOG solutions were kept in a refrigerator while the CNCs reassembled and the TPOG hydrolyzed and condensed, at which point the water was solvent-exchanged with ethanol to afford the corresponding alcogel. Polarized optical microscopy (POM) of these alcogels revealed strong birefringence and fingerprint textures characteristic of chiral nematic organization (Figure 1A). The absence of large aggregates suggested that the germania was well-dispersed. Photographs of the alcogels (Figure 1B) show that the alcogels are translucent, but their opacity increases with the concentration of TPOG. This is likely due to increased concentration of germania NPs, and not aggregation as supported by POM. 5201 https://doi.org/10.1021/acs.chemmater.1c01272 Chem. Mater. 2021, 33, 5197−5209 Chemistry of Materials pubs.acs.org/cm Article Figure 2. SEM images of the (A−D) control and (E−H) high germania loading aerogels. (A) low magnification image of CNC-Control, which is a neat cellulose aerogel; (B, C) high magnification images of CNC-Control; (D) low magnification image of C-Control; (E) low magnification image of CNC/GeO2-300; (F, G) high magnification images of CNC/GeO2-300 (GeO2 NPs highlighted with blue circles); and (H) low magnification image of C/GeO2-300. Figure 3. Compressive mechanical properties of CNC/GeO2 and C/GeO2 aerogels. (A) compressive stress−strain curves; (B) compressive modulus; and (C) compressive strength at 85% strain. composites showed similar degradation onset profiles as CNC aerogels with decomposition beginning around 220 °C.59 For CNC/GeO2 composites, the measured loading of germania was lower than the theoretical loading (Table S2). This loss is attributed to the solvent exchange steps, where a milky white supernatant was occasionally observed. After carbonization, there is an entirely different degradation profile with a main mass loss step occurring between 350 and 400 °C which suggests complete conversion of the cellulose structure into carbon. Additionally, as the concentration of germania increases so too does the thermal stability of the materials with degradation occurring near 450 °C for C/GeO2-300. A slight mass increase at low temperatures was observed in the C/GeO 2 aerogels (and to a lesser extent CNC/GeO 2 aerogels), which we attribute to possible side reactions and oxidation occurring in the air atmosphere. The germania content was notably higher for the carbonized derivatives, with C/GeO2-200 and C/GeO2-300 showing germania loadings of ca. 40 and 60 wt %, respectively. Given that a high metal loading is necessary for energy storage applications, further discussion will pertain to analogues of those two samples. Morphology. The chirality of the prepared aerogels was verified by SEM. Figure 2 shows typical cross sections of the pure CNC and CNC/GeO2-300 aerogels and their carbonized derivatives. All cellulosic aerogels have a twisted layer structure characteristic of left-handed chiral nematic ordering with the apparent density is much larger than the pore volume (VP) calculated from the Barrett−Joyner−Halenda, BJH, method. Since nitrogen sorption can only be used to determine the pore volumes of pores below 300 nm, the difference between VT and VP may be attributed to the existence of macropores. Additionally, a decrease in apparent density is observed with increasing germania content that may correspond to reduced shrinkage of the material during sc-CO2 drying of the alcogel (Table 2). Consequently, this translates into a larger porosity with increasing germania. After carbonization, there is a large increase in the surface area of the materials up to 705 m2 g−1. Those surface areas remain above the results reported for most of the cellulosic aerogels, which usually fail to obtain values exceeding 600 m2 g−1.58 Likely, there is increased accessibility of the pores after CNC degradation. In addition, there was a decrease in VT along with an increase in micropore and mesopore volume. This suggests that although the macrostructure shrinks during the carbonization process, the carbon/ germania backbone prevents collapse of the porous structure, resulting in a substantially higher surface area for the C/GeO2300 aerogels when compared to the Carbon-Control aerogel (695 m2 g−1 versus 518 m2 g−1). Samples were analyzed by TGA under air to determine the amount of germanium oxide present in the materials (Figure S8, Table S2). Although the germanium oxide is stable over 800 °C, its presence does not significantly affect the thermal stability of the CNCs, and the 5202 https://doi.org/10.1021/acs.chemmater.1c01272 Chem. Mater. 2021, 33, 5197−5209 Chemistry of Materials pubs.acs.org/cm pitches of ca. 3 μm for all aerogels (Figure 2A,E). Importantly, this chirality is maintained even after carbonization for all structures (Figure 2D,H) despite shrinkage of the bulk aerogel by up to ca. 87% (the pitch is ca. 2 μm for all carbonized samples). The aerogels also have a vast porous network (Figure 2C), which is important for electrolyte uptake. Germania NPs are well-dispersed throughout the chiral network of CNCs and appear to be 86 ± 22 nm in size (Figure 2G, Figure S2, Video 1). Although some larger microstructures were observed, the majority of germania is indeed nanosized. This is an important finding that hints at the utility of these composite materials for use as electrode materials in supercapacitors as the electrolyte may easily access the pseudocapacitive surface of germania nanoparticles. Mechanical Properties. Determining the compressive properties of the prepared aerogels provides insight into their capacity to withstand applied external forces when used in supercapacitor applications. Accordingly, representative uniaxial compressive stress−strain curves of CNC/GeO2 and C/ GeO2 aerogels are shown in Figure 3A, while the compressive modulus and strength at 85% compression are summarized in Figure 3B,C, respectively. The compressive stress−strain curves are characterized by an elastic behavior at strains below 10% (the compressive stress increases linearly upon strain application) followed by a plastic deformation region and a final stiffening region at larger strains (>25% for C/GeO2 aerogels and >55% for CNC/GeO2 aerogels).60 Upon compression, all aerogels showed a good deformability, accommodating up to 95% strain without breaking or cracking. Compressive modulus values of 180−220 kPa for cellulosic aerogels and 350−400 kPa for carbonaceous aerogels were achieved. The larger modulus observed for carbonized aerogels indicates the formation of a mechanically robust threedimensional structure upon carbonization. This may also explain why an increased surface area and porosity were observed following carbonization despite shrinkage of the bulk material. Similarly, C/GeO2 aerogels show a substantially improved compressive strength at 85% strain when compared to CNC/GeO2 aerogels (ca. 3200 kPa versus ca. 1300 kPa) (see Figure S9). Remarkably, compressive modulus and strength values of CNC/GeO2 aerogels remain well above the results reported for other CNC-based aerogels reported in the literature, which range from 7 to 41 kPa at 80% strain.61 There are two factors that contribute to this improved resistance to deformation. First, as opposed to freeze-drying the aerogels, which is a commonly used approach for aerogel preparation, the aerogels prepared here were obtained through sc-CO2 drying, thereby avoiding pore collapse and keeping the macrostructure of the original wet gel intact.51 Second, our approach yields a highly organized chiral structure with longrange order, which provides enhanced specific strength and toughness. This has been explored by Tripathi et al., who prepared both isotropic cellulose aerogels and chiral nematic cellulose aerogels (following the same method we used) and compared the mechanical properties.62 There was a very clear benefit to the hierarchical ordering, which gave an enhanced specific strength and specific toughness when compared to the isotropic aerogels. Consequently, these enhanced mechanical properties are important for maintaining the porosity and macrostructure of the aerogel during both carbonization and electrochemical testing. To further understand the deformation process of the chiral carbonaceous aerogels, which are especially interesting for Article energy storage applications, we investigated the compression in situ by SEM. We built a custom sample holder comprising two parallel plates where the aerogel thickness was controlled using four screws (Figure S10A,B). The same region of a given aerogel was observed by SEM before and after 30% compression relative to its starting thickness. The micrographs of C/GeO2-300 (Figure S10C,D) show that the original chiral morphology was maintained, with small changes in the helical pitch spacing. As the disordered regions are preferentially deformed, the chiral areas are able to withstand applied external forces with no significant deformation. These results suggest that, similar to many biological systems featuring a twisted plywood structure,63 the hierarchical nanoscale structuring of the aerogels is responsible for the high compressive modulus observed. The highly porous character of aerogels suggests they may be useful for electrochemical energy storage devices.36 Ideally, electrochemical energy storage devices should have a strong affinity toward the liquid electrolyte to provide a good compatibility with conducting media. We immersed the aerogels into a 1 M Na2SO4 electrolyte, observing that the liquid was rapidly absorbed and retained by the aerogel. We defined the electrolyte uptake (EU) after immersing aerogels in 1 M Na2SO4 for 24 h as EU = 100 × (mwet − mdry) mdry (5) where mwet and mdry are the mass of the wet and dry aerogels, respectively. As depicted in Figure S11A, EU values up to 956 and 585% were obtained for CNC-Control and CarbonControl, respectively. Interestingly, these high EU values were obtained despite the predominantly hydrophobic character of the carbonized CNCs. Although the presence of germania slightly lowers the EU due to a reduction of the liquid-holding phase, the obtained results are well above the EU values reported so far for most other aerogel systems including cellulose aerogel membranes (615%),64 bacterial cellulose/ Li0.33La0.557TiO3 aerogel (586%),65 and cellulose/polyacrylamide aerogels (548%).66 The enhanced EU is explained by the fact that the hierarchical, interconnected pore structure of aerogels provides a reduced surface tension and enhanced capillary flow of the electrolyte within the solid67 and that scCO2 drying also helps mitigate pore collapse. Additionally, the oxygen-containing functional groups of CNCs offer a good affinity with 1 M Na2SO4.68 UV−vis measurements of the liquid electrolyte after aerogel soaking were conducted to check the stability of the prepared aerogels in the liquid electrolyte. UV−vis spectra of the resultant solutions are shown in Figure S11B. Although the CNC/GeO2 aerogels released a small amount of CNCs into the electrolyte, as denoted by the absorption maxima in the 250−310 nm range, the aerogels did not redisperse in the solvent. This is in contrast to early reports of nanocellulose aerogels, which could be redispersed unless they underwent additional chemical cross-linking.69 Additionally, the UV−vis spectra of the C/GeO2 aerogels remain barely modified, suggesting that the carbonization step provides a long-lasting physical structure where aerogel components (both carbonized CNCs and GeO2) remain tightly bound. A broad, weakly absorbing species at 275 nm can be seen in the aerogel samples containing germania. It is possible this could be from unbound GeO2 leaching from the 5203 https://doi.org/10.1021/acs.chemmater.1c01272 Chem. Mater. 2021, 33, 5197−5209 Chemistry of Materials pubs.acs.org/cm Article Figure 4. Compressive mechanical properties of electrolyte-soaked CNC/GeO2 and C/GeO2 aerogels. (A) Compressive stress−strain curves at 60% compression for the 1st and 10th cycle for (i) CNC/GeO2-300, (ii) CNC/GeO2-200 (ii), (iii) CNC-Control, (iv) C/GeO2-300, (v) C/GeO2200, and (vi) C-Control aerogels. Mechanical properties from the obtained stress−strain curves: (B) compressive modulus and (C) compressive strength at 60% compression for the 1st and 10th cycles. aerogels suffer from a marked compressive strength decrease upon cycling (up to 45%), while carbon-based aerogels kept their compressive strength strain almost unchanged (<10%). Energy loss coefficient (η) values (further discussion in Figure S14) ranged from 0.7 to 0.9, indicating a stable threedimensional structure provided by the highly porous carbonaceous skeleton, yielding aerogels able to accommodate external stresses without pore collapse (aerogels did not break apart but recovered their original shape upon release, Figure S15.51 A priori, the good mechanical adaptability of these aerogels, which shows no collapse during compression and shaperecovery after release, may result in an improved adhesion and interfacial compatibility when assembled into a supercapacitor, which is a prime requirement for energy storage devices having optimal charge transfer between negative and positive electrodes. This is facilitated by the hierarchical ordering of the cellulose which offers enhanced mechanical properties when compared to its isotropic counterpart, and when coupled with the porous morphology, large specific surface areas, and large electrolyte uptake capacity, the developed aerogels are good candidates to sustain local stresses during supercapacitor applications. Electrochemical Performance. In contrast to brittle silica or early reports of CNC aerogels,69,72 the fabricated aerogels are mechanically strong and keep their structure after compression when soaked in a liquid electrolyte. Such properties are promising for use of these materials in aerogels; however, we have not been able to accurately identify this species. The compressive response of electrolyte-soaked aerogels was studied to assess their mechanical flexibility and ability to withstand multiple loading−unloading cycles without damage (Figure S12). Aerogels soaked in 1 M Na2SO4 were compressed to 60% of their original thickness and then immediately released for 10 successive cycles. Figure 4A shows the representative compression stress−strain curves for the 1st and 10th cycles of the synthesized aerogels (see Figure S13 for all 10 cycles). Generally, all materials showed a continuous compressive stress increase upon loading, but the curves followed different decompression pathways likely due to some structural collapse. To our surprise, C/GeO2 aerogels showed comparable and even improved flexibility and shape recovery performance, in spite of the generally brittle character of the carbonized fibers.70 While CNC/GeO2 aerogels presented a marked hysteresis and have a residual strain of 50% (strain at which 0 kPa is reached during unloading), C/GeO2 aerogels show a lower residual strain. This behavior indicates a better shape recovery of the carbonaceous aerogels with no plastic deformation.71 The compressive modulus varied from ca. 7 kPa for CNC/GeO2 aerogels up to ca. 40 kPa for the carbonaceous analogues (Figure 4B). Similarly, the maximum strength during the first compressive cycle remained in the 10−60 kPa and 330−650 kPa ranges for CNC/GeO2 and C/ GeO2 aerogels, respectively. As shown in Figure 4C, CNC5204 https://doi.org/10.1021/acs.chemmater.1c01272 Chem. Mater. 2021, 33, 5197−5209 Chemistry of Materials pubs.acs.org/cm Article Figure 5. (A) Cyclic voltammograms of aerogels in 1 M Na2SO4 measured at a scan rate of 100 mV s−1; (B) cyclic voltammograms of the C/GeO2300 aerogel in 1 M Na2SO4 for scan rates varying between 10 and 500 mV s−1; (C) gravimetric rate performance of aerogels in 1 M Na2SO4; and (D) cyclic voltammograms of the C/GeO2-200 aerogel after the 1st, 5th, 10th, 20th, 50th, 100th, and 300th cycles. 200, suggesting the importance of having a high germania loading. The CV response of C/GeO2-300 at scan rates between 10 and 500 mV s−1 is summarized in Figure 5B (see Figure S17 for the rate performance of all prepared aerogels). In general, there is an increase in the current with increasing scan rate, which demonstrates good capacitive behavior in the studied voltage window. Further, the area within the CV curves increases with the applied scan rate, and the curves keep their shapes, indicating low ionic transfer resistance at high current rates.77 Figure 5C summarizes the gravimetric rate performance (Cp specific capacitance variation as a function of applied current rate) for all the studied compositions (reported Cp is normalized to the total aerogel mass). It was observed that aerogels containing large amounts of GeO2 present an increased specific capacity for a given current rate, while carbonization increases the charge storage capacity of CNCbased aerogels. These findings confirm the initial hypothesis that the combination of a highly porous hierarchical structure and the presence of GeO2 NPs hosted within an electrically conducting carbonaceous skeleton result in improved energy storage performance. A maximum Cp of 113 F g−1 was achieved for the C/GeO2-300 aerogel at a scan rate of 10 mV s−1. In contrast, neat carbon aerogels had a Cp of 44 F g−1, while the neat CNC aerogel had a Cp of 36 F g−1 (similar to the 34 F g−1 shown by cellulose nanofiber aerogels).28 Although capacities up to 328 F g−1 have been reported for porous carbon aerogels from cellulose upon a carbonizing− activating process,78 the results obtained here are well above the 43.7 F g−1 measured for symmetric CNC/polypyrrole supercapacitors at 2 mV s−179 or the 90 F g−1 obtained for poly(3,4-ethylenedioxythiophene)/nanocellulose electrodes at 1 mA cm−2.80 The good rate stability of our materials arises from the large specific surface area of the aerogels (up to 700 symmetric supercapacitor applications. By using a mesoporous cellulose membrane (see Figure S16), which has already shown good performance in LIBs, in conjunction with the cellulosebased aerogels, we report for the first time a supercapacitor device originating entirely from cellulose.73 The electrochemical properties of aerogels are shown in Figure 5. Cyclic voltammetry (CV) scans of the symmetric supercapacitors containing two identical aerogels separated by the mesoporous CNC membrane soaked in 1 M Na2SO4 are shown in Figure 5A (no binders or conducting additives were incorporated). The curve shape varies depending on the sample, but in general, the aerogels display symmetrical rectangular-shaped curves indicative of electrochemical double-layer capacitors (EDLCs, based on ion adsorption/ desorption).74 C/GeO2-300 presents a distorted symmetrical quasi-rectangular shape related to a pseudocapacitance behavior provided by the redox reactions occurring at the GeO2−carbon interfaces.75 It can be observed that this feature is absent for CNC/GeO2-300. We postulate that the different pore structures achieved during synthesis may be the underlying reason. Indeed, the BET surface area of C/GeO2300 is 695 cm3 g−1 as opposed to 236 cm3 g−1 for the CNC/ GeO2-300 aerogel. In order to achieve the pseudocapacitive contribution, it is necessary to guarantee the exposure of GeO2 to the liquid electrolyte ions.76 Unfortunately, the relatively poor surface area of the CNC/GeO2-300 aerogel denotes a pore clogging effect, reducing the effective GeO2 area exposed to accumulate charges and thus lowering the overall Cp. Thanks to the combination of a pseudocapacitive character with EDLC behavior, the electrochemical performance of C/ GeO2 is effectively enhanced,74 as indicated by the increased area within the CV curve. It is also important to note that this quasi-rectangular shape is significantly attenuated for C/GeO25205 https://doi.org/10.1021/acs.chemmater.1c01272 Chem. Mater. 2021, 33, 5197−5209 Chemistry of Materials pubs.acs.org/cm m2 g−1), allowing for enhanced electrolyte accessibility of that active material, which in turn enables rapid ion diffusion across the electrodes and increases the amount of material capable of undergoing redox reactions.36 Moreover, the mesopores function as electrolyte nanoreservoirs and act as electrolyte ion diffusion channels, further enhancing the supercapacitor performance.81 Cell cycling durability is one of the most relevant parameters determining the practical implementation of supercapacitor electrodes. Extensive cycling often results in undesired large volume changes of the carbon-based electrodes, which in turn reduces the overall Cp of the material over time.82 Therefore, mitigating the mechanical degradation and the associated capacity fading in supercapacitors is critical to obtaining electrochemical energy storage systems with long-life cycles. In this framework, the incorporation of inorganic nanoparticles into 3D hosts has been proven as a suitable way to protect the electrode structure from collapse by buffering the volume changes of the skeleton.83 Accordingly, we assessed the cycling stability of the germania-containing aerogel further at a scan rate of 50 mV s−1 (Figure 5D, see Figure S18 for all aerogels). No shape change was observed, and the aerogel kept adequate charge-storage characteristics for the whole 300 cycles. This is in contrast to the neat carbon aerogel (Carbon-Control, Figure S18F), which showed continuous capacity decay upon cycling. In this context, Figure S19 summarizes the Cp decay after 300 cycles for all of the synthesized aerogels. Generally, the aerogels show a decrease in Cp, with the exception of CNC/ GeO2-300 which shows a 5% Cp increase after 20 cycles, prior to decaying. Such behavior is explained by the relatively poor mechanical properties of CNC aerogels that allow for deformation upon cycling to provide additional active GeO2 surfaces. Overall, carbonization leads to aerogels capable of holding their initial specific capacity to a larger extent; i.e., the neat CNC aerogel keeps ca. 77% of its initial Cp after 300 successive charge/discharge cycles, while the neat carbonized aerogel keeps ca. 83% of its Cp. Remarkably, both in the CNCand carbon-based aerogels, the presence of GeO2 extends the lifetime of the supercapacitors, resulting in enhanced capacity retention values of 91% and 96% for the CNC/GeO2-200 and C/GeO2-200 aerogels, respectively (as opposed to the 77% and 83% achieved for the monolithic CNC and carbon aerogels). Those results are in contrast with the poor cycling stability of pseudocapacitive polymer electrodes, which suffer from structural breakdown during repeated charge/discharge cycles.84 These results prove that the formation of GeO2 nanoparticles within the chiral nematic structure through a sol−gel approach protects both the CNC- and the carbonbased aerogels from undesired structural deterioration during cycling, reducing the capacity fade observed in the control (neat CNC and carbon) samples. This finding has also been observed during mechanical testing in both dry and electrolytesoaked states (Figure 3 and Figure 4), where aerogels containing GeO2 present an enhanced resistance to deformation (seen as a larger compressive modulus and strength). In this way, GeO2 prevents aerogel stacking and specific surface area loss during charge/discharge cycles, promoting efficient ion transport and keeping decent capacities after many cycles. Based on these promising findings, we constructed a solidstate supercapacitor (SSC) using a gel electrolyte that combines ionically conducting media with liquid-leakage-free characteristics.85 As opposed to conventional supercapacitors relying on aqueous or organic-based liquid electrolytes, the Article SSC avoids electrolyte leakage issues and can achieve larger energy densities (i.e., lighter devices for a given delivered energy). Nowadays, poly(vinyl alcohol) is a popular choice for SSCs because of its good gelling ability and chemical/ mechanical stability.86 We replaced poly(vinyl alcohol) with a cellulosic gel electrolyte to construct a solid-state symmetric supercapacitor. Although the performance of solid-state energy storage devices remains below that of traditional systems due to limited ion transfer at electrode−electrolyte interfaces and reduced ionic conductivities, their improved safety makes them attractive alternatives to liquid systems.87 To the best of our knowledge, this is the first example showing the development of a solid-state symmetric supercapacitor fully based on renewable resources (modern supercapacitors require petroleum-derived materials soaked in a liquid electrolyte36 or poly(vinyl alcohol)/Na2SO4 gels).74 The electrochemical characterization of the solid-state symmetric supercapacitor comprised of C/GeO2 aerogels is shown in Figure S20. We found that the gel electrolyte synthesis plays a pivotal role in ensuring an efficient ion transfer between aerogel electrodes. Long thermal treatments result in extensive gel cross-linking, which in turn limits the ion migration process within the gel electrolyte.88 As a result, CV curves with extremely low current densities were obtained (Figure S20A). Limiting the double esterification cross-linking to 5 min ensures an adequate balance between cross-linking (supercapacitor safety, electrically insulating both electrodes) and ionic conductivity. As a consequence, CV curves in Figure S20B are characterized by a combination of an EDLC behavior of carbon (ion adsorption/ desorption) with the pseudocapacitance of germania (reversible redox reactions), providing a Cp of 29 F g−1 at 10 mV s−1 (14 F g−1 at 500 mV s−1). That said, there is still room for improvement as obtained Cp values can be further increased by optimizing the synthesis of the cellulose gel. Similar to supercapacitors having a liquid electrolyte, the prepared solidstate symmetric supercapacitors show long-term stability, holding 90% of their initial capacity after 250 cycles at 50 mV s−1 (Figure S20C,D). Those results reveal the suitability of binder-free high-surface-area carbon/germania aerogels for energy storage applications, including symmetric solid-state supercapacitors based on renewable resources, of which scarce examples exist in the literature. ■ CONCLUSIONS We report the development of high surface area cellulose and carbon germania aerogel composite materials with high porosity and chiral nematic order for use in supercapacitors. In preparing these materials, we demonstrated a simple method for incorporating highly reactive precursors into carbonaceous supports while retaining long-range order. Indepth compressive mechanical measurements demonstrated the utility of having a chiral nematic structure in the aerogel, which prevents collapse of the macrostructure during carbonization as well as during electrochemical testing. This is important for maintaining a high porosity and surface of the material which ultimately results in high electrolyte uptake (>500%). The ordered chiral nematic structure also serves as a pathway for efficient electron transport within the whole 3D skeleton, which is vital for electrochemical applications. Preparation of symmetric supercapacitors based entirely on CNCs showed good specific capacitance (ca. 114 F g−1) and retention of up to 95% after 300 cycles at a scan rate of 50 mV s−1. The presence of GeO2 not only increased the specific 5206 https://doi.org/10.1021/acs.chemmater.1c01272 Chem. Mater. 2021, 33, 5197−5209 Chemistry of Materials pubs.acs.org/cm HORSE), Bioimaging Facility (BIF), and Shared Instrument Facility (SIF) for assistance with XRD, SEM, and TGA, respectively. The authors would also like to acknowledge Dr. Andreas Schertel and Carl Zeiss Microscopy GmbH for FIBSEM measurements and Dr. Andy Tran for designing the graphics in Scheme 1. The authors are grateful for the Open Access funding provided by the University of Basque Country (UPV/EHU). capacitance of the carbon aerogels by combining the inherent EDLC behavior of carbon (ion adsorption/desorption) with the pseudocapacitance of germania (reversible redox reactions) but also resulted in symmetric supercapacitors with an enhanced life span. These results reveal the suitability of binder-free high-surface-area germania/carbon aerogels for energy storage applications, including symmetric solid-state supercapacitors based on renewable resources. ■ ■ ASSOCIATED CONTENT sı Supporting Information * REFERENCES (1) Lizundia, E.; Kundu, D. Advances in Natural Biopolymer-Based Electrolytes and Separators for Battery Applications. Adv. Funct. Mater. 2021, 31, 2005646. (2) Berglund, L. A.; Burgert, I. Bioinspired Wood Nanotechnology for Functional Materials. Adv. Mater. 2018, 30, 1704285. (3) Li, T.; Chen, C.; Brozena, A. H.; Zhu, J. Y.; Xu, L.; Driemeier, C.; Dai, J.; Rojas, O. J.; Isogai, A.; Wågberg, L.; Hu, L. Developing Fibrillated Cellulose as a Sustainable Technological Material. Nature 2021, 590, 47−56. (4) Altaner, C. M.; Thomas, L. H.; Fernandes, A. N.; Jarvis, M. C. How Cellulose Stretches: Synergism between Covalent and Hydrogen Bonding. Biomacromolecules 2014, 15, 791−798. (5) Wei, Z.; Cai, C.; Huang, Y.; Wang, P.; Song, J.; Deng, L.; Fu, Y. Strong Biodegradable Cellulose Materials with Improved Crystallinity via Hydrogen Bonding Tailoring Strategy for UV Blocking and Antioxidant Activity. Int. J. Biol. Macromol. 2020, 164, 27−36. (6) Habibi, Y.; Lucia, L. A.; Rojas, O. J. Cellulose Nanocrystals: Chemistry, Self-Assembly, and Applications. Chem. Rev. 2010, 110, 3479−3500. (7) Rånby, B. G.; Banderet, A.; Sillén, L. G. Aqueous Colloidal Solutions of Cellulose Micelles. Acta Chem. Scand. 1949, 3, 649−650. (8) Revol, J.-F.; Godbout, L.; Dong, X.-M.; Gray, D. G.; Chanzy, H.; Maret, G. Chiral Nematic Suspensions of Cellulose Crystallites; Phase Separation and Magnetic Field Orientation. Liq. Cryst. 1994, 16, 127−134. (9) Marchessault, R. H.; Morehead, F. F.; Walter, N. M. Liquid Crystal Systems from Fibrillar Polysaccharides. Nature 1959, 184, 632−633. (10) Revol, J.-F.; Bradford, H.; Giasson, J.; Marchessault, R. H.; Gray, D. G. Helicoidal Self-Ordering of Cellulose Microfibrils in Aqueous Suspension. Int. J. Biol. Macromol. 1992, 14, 170−172. (11) Guidetti, G.; Atifi, S.; Vignolini, S.; Hamad, W. Y. Flexible Photonic Cellulose Nanocrystal Films. Adv. Mater. 2016, 28, 10042− 10047. (12) Walters, C. M.; Boott, C. E.; Nguyen, T. D.; Hamad, W. Y.; MacLachlan, M. J. Iridescent Cellulose Nanocrystal Films Modified with Hydroxypropyl Cellulose. Biomacromolecules 2020, 21, 1295− 1302. (13) Shopsowitz, K. E.; Qi, H.; Hamad, W. Y.; MacLachlan, M. J. Free-Standing Mesoporous Silica Films with Tunable Chiral Nematic Structures. Nature 2010, 468, 422−425. (14) He, Y.-D.; Zhang, Z.-L.; Xue, J.; Wang, X.-H.; Song, F.; Wang, X.-L.; Zhu, L.-L.; Wang, Y.-Z. Biomimetic Optical Cellulose Nanocrystal Films with Controllable Iridescent Color and Environmental Stimuli-Responsive Chromism. ACS Appl. Mater. Interfaces 2018, 10, 5805−5811. (15) Tang, J.; Berry, R. M.; Tam, K. C. Stimuli-Responsive Cellulose Nanocrystals for Surfactant-Free Oil Harvesting. Biomacromolecules 2016, 17, 1748−1756. (16) Zhang, J.-H.; Xie, S.-M.; Zhang, M.; Zi, M.; He, P.-G.; Yuan, L.M. Novel Inorganic Mesoporous Material with Chiral Nematic Structure Derived from Nanocrystalline Cellulose for High-Resolution Gas Chromatographic Separations. Anal. Chem. 2014, 86, 9595− 9602. (17) Walters, C. M.; Adair, K. R.; Hamad, W. Y.; MacLachlan, M. J. Synthesis of Chiral Nematic Mesoporous Metal and Metal Oxide Nanocomposites and their Use as Heterogeneous Catalysts. Eur. J. Inorg. Chem. 2020, 2020, 3937−3943. The Supporting Information is available free of charge at https://pubs.acs.org/doi/10.1021/acs.chemmater.1c01272. PXRD, Raman, TGA, nitrogen sorption isotherms, SEM, mechanical testing, electrolyte uptake, and CV data of the studied aerogels (PDF) FIB-SEM milling video (MP4) ■ Article AUTHOR INFORMATION Corresponding Authors Mark J. MacLachlan − Department of Chemistry, University of British Columbia, Vancouver, British Columbia V6T 1Z1, Canada; Stewart Blusson Quantum Matter Institute, University of British Columbia, Vancouver, British Columbia V6T 1Z4, Canada; WPI Nano Life Science Institute, Kanazawa University, Kanazawa, Ishikawa 920-1192, Japan; orcid.org/0000-0002-3546-7132; Email: mmaclach@chem.ubc.ca Erlantz Lizundia − Life Cycle Thinking Group, Department of Graphic Design and Engineering Projects, Faculty of Engineering in Bilbao, University of the Basque Country (UPV/EHU), Bilbao 48013, Spain; BCMaterials, Basque Center for Materials, Applications and Nanostructures, 48940 Leioa, Spain; Email: erlantz.liizundia@ehu.eus Authors Christopher M. Walters − Department of Chemistry, University of British Columbia, Vancouver, British Columbia V6T 1Z1, Canada Gunwant K. Matharu − Department of Chemistry, University of British Columbia, Vancouver, British Columbia V6T 1Z1, Canada Wadood Y. Hamad − Transformation and Interfaces Group, Bioproducts Innovation Centre of Excellence, FPInnovations, Vancouver, British Columbia V6T 1Z4, Canada; orcid.org/0000-0003-1376-5865 Complete contact information is available at: https://pubs.acs.org/10.1021/acs.chemmater.1c01272 Author Contributions The manuscript was written through contributions of all authors. All authors have given approval to the final version of the manuscript. Funding M.J.M. thanks NSERC for funding (Discovery Grant, CREATE Nanomat Grant). Notes The authors declare no competing financial interest. ■ ACKNOWLEDGMENTS The authors would like to thank The University of British Columbia’s Centre for Higher Order Structure Elucidation (C5207 https://doi.org/10.1021/acs.chemmater.1c01272 Chem. Mater. 2021, 33, 5197−5209 Chemistry of Materials pubs.acs.org/cm (18) Boott, C. E.; Tran, A.; Hamad, W. Y.; MacLachlan, M. J. Cellulose Nanocrystal Elastomers with Reversible Visible Color. Angew. Chem., Int. Ed. 2020, 59, 226−231. (19) Zhuo, H.; Hu, Y.; Chen, Z.; Peng, X.; Lai, H.; Liu, L.; Liu, Q.; Liu, C.; Zhong, L. Linking Renewable Cellulose Nanocrystal into Lightweight and Highly Elastic Carbon Aerogel. ACS Sustainable Chem. Eng. 2020, 8, 11921−11929. (20) Ke, F.-S.; Mishra, K.; Jamison, L.; Peng, X.-X.; Ma, S.-G.; Huang, L.; Sun, S.-G.; Zhou, X.-D. Tailoring Nanostructures in Micrometer Size Germanium Particles to Improve their Performance as an Anode for Lithium Ion Batteries. Chem. Commun. 2014, 50, 3713−3715. (21) Hayner, C. M.; Zhao, X.; Kung, H. H. Materials for Rechargeable Lithium-Ion Batteries. Annu. Rev. Chem. Biomol. Eng. 2012, 3, 445−471. (22) Hwang, J.; Jo, C.; Kim, M. G.; Chun, J.; Lim, E.; Kim, S.; Jeong, S.; Kim, Y.; Lee, J. Mesoporous Ge/GeO2/Carbon Lithium-Ion Battery Anodes with High Capacity and High Reversibility. ACS Nano 2015, 9, 5299−5309. (23) Wang, X.; Liu, B.; Wang, Q.; Song, W.; Hou, X.; Chen, D.; Cheng, Y.-B.; Shen, G. Three-Dimensional Hierarchical GeSe2 Nanostructures for High Performance Flexible All-Solid-State Supercapacitors. Adv. Mater. 2013, 25, 1479−1486. (24) Yang, B.; Nie, A.; Chang, Y.; Cheng, Y.; Wen, F.; Xiang, J.; Li, L.; Liu, Z.; Tian, Y. Metallic Layered Germanium Phosphide GeP5 for High Rate Flexible All-Solid-State Supercapacitors. J. Mater. Chem. A 2018, 6, 19409−19416. (25) Velmurugan, V.; Srinivasarao, U.; Ramachandran, R.; Saranya, M.; Grace, A. N. Synthesis of Tin Oxide/Graphene (SnO2/G) Nanocomposite and its Electrochemical Properties for Supercapacitor Applications. Mater. Res. Bull. 2016, 84, 145−151. (26) Lim, S. P.; Huang, N. M.; Lim, H. N. Solvothermal Synthesis of SnO2/Graphene Nanocomposites for Supercapacitor Application. Ceram. Int. 2013, 39, 6647−6655. (27) Choudhury, A.; Dalal, A.; Dhar Dwivedi, S. M. M.; Ghosh, A.; Halder, N.; Das, S.; Mondal, A. Vapour Transport Grown Photosensitive GeO2 Thin Film. Mater. Res. Bull. 2021, 142, 111397. (28) Liu, P.; Ru, Q.; Zheng, P.; Shi, Z.; Liu, Y.; Su, C.; Hou, X.; Su, S.; Chi-Chung Ling, F. One-Step Synthesis of Zn2GeO4/CNT-O Hybrid with Superior Cycle Stability for Supercapacitor Electrodes. Chem. Eng. J. 2019, 374, 29−38. (29) Augustyn, V.; Simon, P.; Dunn, B. Pseudocapacitive Oxide Materials for High-Rate Electrochemical Energy Storage. Energy Environ. Sci. 2014, 7, 1597−1614. (30) Saha, D.; Kruse, P. Conductive Forms of MoS2 and Their Applications in Energy Storage and Conversion. J. Electrochem. Soc. 2020, 167, 126517. (31) Wang, R.; Yao, M.; Niu, Z. Smart Supercapacitors from Materials to Devices. InfoMat 2020, 2, 113−125. (32) Zhu, M.; Huang, Y.; Huang, Y.; Pei, Z.; Xue, Q.; Li, H.; Geng, H.; Zhi, C. Capacitance Enhancement in a Semiconductor Nanostructure-Based Supercapacitor by Solar Light and a SelfPowered Supercapacitor−Photodetector System. Adv. Funct. Mater. 2016, 26, 4481−4490. (33) Bushick, K.; Mengle, K. A.; Chae, S.; Kioupakis, E. Electron and Hole Mobility of Rutile GeO2 from First Principles: An UltrawideBandgap Semiconductor for Power Electronics. Appl. Phys. Lett. 2020, 117, 182104. (34) Peng, H.; Yan, B.; Jiang, M.; Liu, B.; Gu, Y.; Yao, G.; Zhang, Y.; Ye, L.; Bai, X.; Chen, S. A Coral-Like Polyaniline/Barium Titanate Nanocomposite Electrode with Double Electric Polarization for Electrochromic Energy Storage Applications. J. Mater. Chem. A 2021, 9, 1669−1677. (35) Liu, Y. X., Liang; Wang, M. Barium Titanate-Doped Super Capacitor Electrode Material Having High Dielectric Constant and Preparation Method Thereof. Chinese Patent CN106024406A, 2016. (36) Yang, X.; Shi, K.; Zhitomirsky, I.; Cranston, E. D. Cellulose Nanocrystal Aerogels as Universal 3D Lightweight Substrates for Supercapacitor Materials. Adv. Mater. 2015, 27, 6104−6109. Article (37) Chen, S.; Xing, W.; Duan, J.; Hu, X.; Qiao, S. Z. Nanostructured Morphology Control for Efficient Supercapacitor Electrodes. J. Mater. Chem. A 2013, 1, 2941−2954. (38) Du, A.; Zhou, B.; Zhang, Z.; Shen, J. A Special Material or a New State of Matter: A Review and Reconsideration of the Aerogel. Materials 2013, 6, 941−968. (39) Barrios, E.; Fox, D.; Li Sip, Y. Y.; Catarata, R.; Calderon, J. E.; Azim, N.; Afrin, S.; Zhang, Z.; Zhai, L. Nanomaterials in Advanced, High-Performance Aerogel Composites: A Review. Polymers 2019, 11, 726. (40) Chen, G.; Chen, B.; Liu, T.; Mei, Y.; Ren, H.; Bi, Y.; Luo, X.; Zhang, L. The Synthesis and Characterization of Germanium Oxide Aerogel. J. Non-Cryst. Solids 2012, 358, 3322−3326. (41) Fang, S.; Shen, L.; Zheng, H.; Zhang, X. Ge−Graphene− Carbon Nanotube Composite Anode for High Performance LithiumIon Batteries. J. Mater. Chem. A 2015, 3, 1498−1503. (42) Li, D.; Wang, H.; Liu, H. K.; Guo, Z. A New Strategy for Achieving a High Performance Anode for Lithium Ion Batteries Encapsulating Germanium Nanoparticles in Carbon Nanoboxes. Adv. Energy Mater. 2016, 6, 1501666. (43) Meng, X.; Al-Salman, R.; Zhao, J.; Borissenko, N.; Li, Y.; Endres, F. Electrodeposition of 3D Ordered Macroporous Germanium from Ionic Liquids: A Feasible Method to Make Photonic Crystals with a High Dielectric Constant. Angew. Chem., Int. Ed. 2009, 48, 2703−2707. (44) Armatas, G. S.; Kanatzidis, M. G. Mesostructured Germanium with Cubic Pore Symmetry. Nature 2006, 441, 1122−1125. (45) Xu, Y.-T.; Dai, Y.; Nguyen, T.-D.; Hamad, W. Y.; MacLachlan, M. J. Aerogel Materials with Periodic Structures Imprinted with Cellulose Nanocrystals. Nanoscale 2018, 10, 3805−3812. (46) Nguyen, T.-D.; Lizundia, E.; Niederberger, M.; Hamad, W. Y.; MacLachlan, M. J. Self-Assembly Route to TiO2 and TiC with a Liquid Crystalline Order. Chem. Mater. 2019, 31, 2174−2181. (47) Puech, P.; Kandara, M.; Paredes, G.; Moulin, L.; Weiss-Hortala, E.; Kundu, A.; Ratel-Ramond, N.; Plewa, J.-M.; Pellenq, R.; Monthioux, M. Analyzing the Raman Spectra of Graphenic Analyzing the Raman Spectra of Graphenic Carbon Materials from Kerogens to Nanotubes: What Type of Information Can Be Extracted from Defect Bands? C 2019, 5, 69. (48) Lizundia, E.; Nguyen, T.-D.; Vilas, J. L.; Hamad, W. Y.; MacLachlan, M. J. Chiroptical, Morphological and Conducting Properties of Chiral Nematic Mesoporous Cellulose/Polypyrrole Composite Films. J. Mater. Chem. A 2017, 5, 19184−19194. (49) Casas, X.; Niederberger, M.; Lizundia, E. A Sodium-Ion Battery Separator with Reversible Voltage Response Based on Water-Soluble Cellulose Derivatives. ACS Appl. Mater. Interfaces 2020, 12, 29264− 29274. (50) Adachi, T.; Sakka, S. The Role of N,N-dimethylformamide, a DCCA, in the Formation of Silica Gel Monoliths by Sol-Gel Method. J. Non-Cryst. Solids 1988, 99, 118−128. (51) Zhou, L.; Zhai, Y.-M.; Yang, M.-B.; Yang, W. Flexible and Tough Cellulose Nanocrystal/Polycaprolactone Hybrid Aerogel Based on the Strategy of Macromolecule Cross-Linking via Click Chemistry. ACS Sustainable Chem. Eng. 2019, 7, 15617−15627. (52) McMurdie, H. F.; Morris, M. C.; Evans, E. H.; Paretzkin, B.; Wong-Ng, W.; Ettlinger, L.; Hubbard, C. R. Standard X-Ray Diffraction Powder Patterns from the JCPDS Research Associateship. Powder Diffr. 1986, 1, 64−77. (53) Patterson, A. L. The Scherrer Formula for X-Ray Particle Size Determination. Phys. Rev. 1939, 56, 978−982. (54) Kim, H.; Viswanathamurthi, P.; Bhattarai, N.; Lee, D. Preparation and Morphology of Germanium Oxide Nanofibers. Rev. Adv. Mater. Sci. 2003, 5, 220−223. (55) Eom, Y.; Son, S. M.; Kim, Y. E.; Lee, J.-E.; Hwang, S.-H.; Chae, H. G. Structure Evolution Mechanism of Highly Ordered Graphite During Carbonization of Cellulose Nanocrystals. Carbon 2019, 150, 142−152. (56) Zhu, H.; Shen, F.; Luo, W.; Zhu, S.; Zhao, M.; Natarajan, B.; Dai, J.; Zhou, L.; Ji, X.; Yassar, R. S.; Li, T.; Hu, L. Low Temperature 5208 https://doi.org/10.1021/acs.chemmater.1c01272 Chem. Mater. 2021, 33, 5197−5209 Chemistry of Materials pubs.acs.org/cm Carbonization of Cellulose Nanocrystals for High Performance Carbon Anode of Sodium-Ion Batteries. Nano Energy 2017, 33, 37−44. (57) Sing, K. S. W.; Everett, D. H.; Haul, R. A. W.; Moscou, L.; Pierotti, R. A.; Rouquérol, J.; Simieniewska, T. Reporting Physisorption Data for Gas/Solid Systems with Special Reference to the Determination of Surface Area and Porosity. Pure Appl. Chem. 1985, 57, 603−619. (58) Zaman, A.; Huang, F.; Jiang, M.; Wei, W.; Zhou, Z. Preparation, Properties, and Applications of Natural Cellulosic Aerogels: A Review. Energy Built Environ. 2020, 1, 60−76. (59) Roman, M.; Winter, W. T. Effect of Sulfate Groups from Sulfuric Acid Hydrolysis on the Thermal Degradation Behavior of Bacterial Cellulose. Biomacromolecules 2004, 5, 1671−1677. (60) Wicklein, B.; Kocjan, A.; Salazar-Alvarez, G.; Carosio, F.; Camino, G.; Antonietti, M.; Bergström, L. Thermally Insulating and Fire-Retardant Lightweight Anisotropic Foams Based on Nanocellulose and Graphene Oxide. Nat. Nanotechnol. 2015, 10, 277−283. (61) Abraham, E.; Weber, D. E.; Sharon, S.; Lapidot, S.; Shoseyov, O. Multifunctional Cellulosic Scaffolds from Modified Cellulose Nanocrystals. ACS Appl. Mater. Interfaces 2017, 9, 2010−2015. (62) Tripathi, A.; Tardy, B. L.; Khan, S. A.; Liebner, F.; Rojas, O. J. Expanding the Upper Limits of Robustness of Cellulose Nanocrystal Aerogels: Outstanding Mechanical Performance and Associated Pore Compression Response of Chiral-Nematic Architectures. J. Mater. Chem. A 2019, 7, 15309−15319. (63) Fabritius, H.-O.; Sachs, C.; Triguero, P. R.; Raabe, D. Influence of Structural Principles on the Mechanics of a Biological Fiber-Based Composite Material with Hierarchical Organization: The Exoskeleton of the Lobster Homarus americanus. Adv. Mater. 2009, 21, 391−400. (64) Wan, J.; Zhang, J.; Yu, J.; Zhang, J. Cellulose Aerogel Membranes with a Tunable Nanoporous Network as a Matrix of Gel Polymer Electrolytes for Safer Lithium-Ion Batteries. ACS Appl. Mater. Interfaces 2017, 9, 24591−24599. (65) Ding, C.; Fu, X.; Li, H.; Yang, J.; Lan, J.-L.; Yu, Y.; Zhong, W.H.; Yang, X. An Ultrarobust Composite Gel Electrolyte Stabilizing Ion Deposition for Long-Life Lithium Metal Batteries. Adv. Funct. Mater. 2019, 29, 1904547. (66) Li, L.; Lu, F.; Wang, C.; Zhang, F.; Liang, W.; Kuga, S.; Dong, Z.; Zhao, Y.; Huang, Y.; Wu, M. Flexible Double-Cross-Linked Cellulose-Based Hydrogel and Aerogel Membrane for Supercapacitor Separator. J. Mater. Chem. A 2018, 6, 24468−24478. (67) Haller, P. D.; Bradley, L. C.; Gupta, M. Effect of Surface Tension, Viscosity, and Process Conditions on Polymer Morphology Deposited at the Liquid−Vapor Interface. Langmuir 2013, 29, 11640−11645. (68) Zhang, J.; Yue, L.; Kong, Q.; Liu, Z.; Zhou, X.; Zhang, C.; Xu, Q.; Zhang, B.; Ding, G.; Qin, B.; Duan, Y.; Wang, Q.; Yao, J.; Cui, G.; Chen, L. Sustainable, Heat-Resistant and Flame-Retardant CelluloseBased Composite Separator for High-Performance Lithium Ion Battery. Sci. Rep. 2015, 4, 3935. (69) Heath, L.; Thielemans, W. Cellulose Nanowhisker Aerogels. Green Chem. 2010, 12, 1448−1453. (70) Cho, M.; Karaaslan, M. A.; Renneckar, S.; Ko, F. Enhancement of the Mechanical Properties of Electrospun Lignin-Based Nanofibers by Heat Treatment. J. Mater. Sci. 2017, 52, 9602−9614. (71) Qin, Y.; Peng, Q.; Ding, Y.; Lin, Z.; Wang, C.; Li, Y.; Xu, F.; Li, J.; Yuan, Y.; He, X.; Li, Y. Lightweight, Superelastic, and Mechanically Flexible Graphene/Polyimide Nanocomposite Foam for Strain Sensor Application. ACS Nano 2015, 9, 8933−8941. (72) Parmenter, K. E.; Milstein, F. Mechanical Properties of Silica Aerogels. J. Non-Cryst. Solids 1998, 223, 179−189. (73) Hänsel, C.; Lizundia, E.; Kundu, D. A Single Li-Ion Conductor Based on Cellulose. ACS Appl. Energy Mater. 2019, 2, 5686−5691. (74) Zhang, Y.; Shang, Z.; Shen, M.; Chowdhury, S. P.; Ignaszak, A.; Sun, S.; Ni, Y. Cellulose Nanofibers/Reduced Graphene Oxide/ Polypyrrole Aerogel Electrodes for High-Capacitance Flexible AllSolid-State Supercapacitors. ACS Sustainable Chem. Eng. 2019, 7, 11175−11185. Article (75) Ryu, J.; Hong, D.; Shin, S.; Choi, W.; Kim, A.; Park, S. Hybridizing Germanium Anodes with Polysaccharide-Derived Nitrogen-Doped Carbon for High Volumetric Capacity of Li-Ion Batteries. J. Mater. Chem. A 2017, 5, 15828−15837. (76) Yu, Z.; Tetard, L.; Zhai, L.; Thomas, J. Supercapacitor Electrode Materials: Nanostructures From 0 to 3 Dimensions. Energy Environ. Sci. 2015, 8, 702−730. (77) Huang, Y.; Zhong, M.; Huang, Y.; Zhu, M.; Pei, Z.; Wang, Z.; Xue, Q.; Xie, X.; Zhi, C. A Self-Healable and Highly Stretchable Supercapacitor Based on a Dual Crosslinked Polyelectrolyte. Nat. Commun. 2015, 6, 10310. (78) Zhuo, H.; Hu, Y.; Tong, X.; Zhong, L.; Peng, X.; Sun, R. Sustainable Hierarchical Porous Carbon Aerogel from Cellulose for High-Performance Supercapacitor and CO2 Capture. Ind. Crops Prod. 2016, 87, 229−235. (79) Shi, K.; Yang, X.; Cranston, E. D.; Zhitomirsky, I. Efficient Lightweight Supercapacitor with Compression Stability. Adv. Funct. Mater. 2016, 26, 6437−6445. (80) Wang, Z.; Tammela, P.; Huo, J.; Zhang, P.; Strømme, M.; Nyholm, L. Solution-Processed Poly(3,4-ethylenedioxythiophene) Nanocomposite Paper Electrodes for High-Capacitance Flexible Supercapacitors. J. Mater. Chem. A 2016, 4, 1714−1722. (81) Zheng, W.; Lv, R.; Na, B.; Liu, H.; Jin, T.; Yuan, D. Nanocellulose-Mediated Hybrid Polyaniline Electrodes for High Performance Flexible Supercapacitors. J. Mater. Chem. A 2017, 5, 12969−12976. (82) Liu, Z.; Yuan, X.; Zhang, S.; Wang, J.; Huang, Q.; Yu, N.; Zhu, Y.; Fu, L.; Wang, F.; Chen, Y.; Wu, Y. Three-Dimensional Ordered Porous Electrode Materials for Electrochemical Energy Storage. NPG Asia Mater. 2019, 11, 12. (83) Zeng, Y.-F.; Xin, G.-X.; Bulin, C.-K.; Zhang, B.-W. One-Step Preparation and Electrochemical Performance of 3D Reduced Graphene Oxide/NiO as Supercapacitor Electrodes Materials. Wuji Cailiao Xuebao 2018, 33, 1070−1076. (84) Liu, T.; Finn, L.; Yu, M.; Wang, H.; Zhai, T.; Lu, X.; Tong, Y.; Li, Y. Polyaniline and Polypyrrole Pseudocapacitor Electrodes with Excellent Cycling Stability. Nano Lett. 2014, 14, 2522−2527. (85) Ye, T.; Zou, Y.; Xu, W.; Zhan, T.; Sun, J.; Xia, Y.; Zhang, X.; Yang, D. Poorly-Crystallized Poly(Vinyl Alcohol)/Carrageenan Matrix: Highly Ionic Conductive and Flame-Retardant Gel Polymer Electrolytes for Safe and Flexible Solid-State Supercapacitors. J. Power Sources 2020, 475, 228688. (86) Yan, T.; Zou, Y.; Zhang, X.; Li, D.; Guo, X.; Yang, D. Hydrogen Bond Interpenetrated Agarose/PVA Network: A Highly Ionic Conductive and Flame-Retardant Gel Polymer Electrolyte. ACS Appl. Mater. Interfaces 2021, 13, 9856−9864. (87) Yang, Y. A Mini-Review: Emerging All-Solid-State Energy Storage Electrode Materials for Flexible Devices. Nanoscale 2020, 12, 3560−3573. (88) Zhou, Y.; Wan, C.; Yang, Y.; Yang, H.; Wang, S.; Dai, Z.; Ji, K.; Jiang, H.; Chen, X.; Long, Y. Highly Stretchable, Elastic, and Ionic Conductive Hydrogel for Artificial Soft Electronics. Adv. Funct. Mater. 2019, 29, 1806220. 5209 https://doi.org/10.1021/acs.chemmater.1c01272 Chem. Mater. 2021, 33, 5197−5209