2022-10-21 Chloride ion migration in capillar-porous system of marine concrete 100

реклама

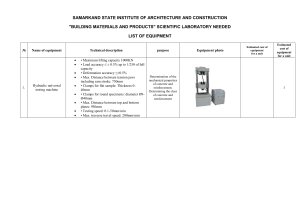

Chloride ion transport in capillarporous system of marine concrete Lev V. Kim assoc. professor, PhD, Polytechnic Inst., Dept Marine Arctic Technologies Advisor Russian Academy of Architecture and Constr. Sc. (RAACS), Member of RAACS Scientific Council of destruction concrete and other building materials Vladivostok 2022 INTRODUCTION 2 ARCTIC CHALLENGIES (source: Guidance for offshore operation in the Barents Sea – JIP “Barents-2020”) • Low temperatures • Working Environment • Cold Flow • Selection of materials • Ice • Sea ice and ice loads • Icebergs and Ice management • Icing • Darkness • Working environment • Rescue • Remoteness • Emergency preparedness • Transportation of personnel and equipment • Vulnerable Environment 3 The Sea of Okhotsk 4 Far Eastern Federal district of Russia Deterioration types: Chloride deterioration - 66 %, Carbonation – 5 %, Frost attack – 5 %, Other – 24 %. Sakhalin island climate conditions • on the boundary of matrix Cracks with aggregate. Pores in cement stone with cracks. Table 1. Average amount of days with raining and time of humidity Offshore zone along eastern coast of Sakhalin island North-East East Southern-East Days with rainfalls hNd≥2.5 mm/year 167 147 99 Humid period ToW, years 0.464 0.408 0.275 Offshore and port objects 7 Durability of concrete means ability of concrete to resist weathering action, chemical attack, abrasion, settlement/deflection/deformation within specified limit or any process of deterioration. Permeability is the property that governs the rate of flow of a fluid into a porous solid. One of the major causes is high content of void/porosity (in cement past, aggregates, and concrete) which may lead to earlier failure of concrete structures. Air content in concrete shall not exceed more than 2.5 % and in reinforced concrete, any crack of width more than 0.3 mm under loaded conditions needs more attentions to protect from, water/acid rains causing chemical and physical processes of degradation. For deterioration by surface wear, abrasion by dry attrition (wear on pavements and industrial floors by traffic) special attention shall be given to the quality of concrete surface. 8 Testing of concrete of structures in ports Kholmsk and Korsakov, Sakhalin, 2018 9 Reinforced concrete is widely used in the marine environment (docks and harbours, quays, jetties, wharves, seawalls, pipelines, tunnels etc.). External causes of deterioration: 1) physical: moisture content, temperature, freezing/thawing; 2) chemical: aggressive gases and liquids; 3) mechanical: load, friction and vibration. It is known that the degradation process is strongly influenced by the environmental conditions. The rates of most deterioration processes are controlled by the transport of particular aggressive species through the concrete cover. Goal of work - to study the various transport mechanisms that may take place in the deterioration of a concrete structure. 10 1. Permeability, capillary and pore system, chloride ion migration, reinforcement damage 11 Pile structure 12 Gravity structure Concrete durability problems arise from the aggressiveness of the environment to which the structure is exposed. The main reasons for such durability problems are the interconnected porous nature of the hydrated cement paste. Exposure conditions in the marine environment (BS 6349-1 Maritime Structures Part 1: Code of Practice for General Criteria. British Standards, London, UK, 2000) The is no simple relationship between strength and any of the durability parameters. 13 14 There are 3 basic visual symptoms of distress: • cracking; • spalling; • disintegration. Although each of the basic symptoms is readily differentiated from the others, each occurs in several forms, each having a different significance. A great number of models describing the continuum behavior, phase transitions in them, criteria of ice body destruction and fragmentation under the load as well as the continual destruction models are known. Marine effects: aggression chloride, the transport of salt solutions, chemical degradation, cyclic freezing-thawing, low temperature, etc. reduce the durability. 15 The sea water have typical salt content 30-35 g/liter and the ions present Na+, Mg+2,Cl-, and (So4)2- and also gases. They plays an important part in the chemical and electrochemical phenomena influencing concrete durability. Oxygen (O2) in the air and in water, varying concentrations of dissolved carbon dioxide (CO2) and hydrogen sulfide (H2S) may cause lowering of the pH from its normal value 8.2-8.4 to 7 or even less. Acidic waters reduce the alkalinity and strength of concrete, and enhance the electrochemical corrosion of the embedded steel. Marine growth involving barnacles and mollusks are frequently found on the surface of porous concrete whose alkalinity has been greatly reduced by leaching. 16 17 Concrete fracture failure Physical Chemical Impacts Carbonation Ice action chlorides Wave action sulfates Wave + Ice action Design External causes of deterioration influencing on durability of concrete: 1) main physical factors: moisture content, temperature, freezing and thawing; 2) main chemical factors: aggressive gases and liquids; 3) main mechanical factors: load, friction and vibration. The phenomenon which induces such distress may be associated with one of the phases (e.g. design, construction, operation). There are 3 basic visual symptoms of distress: - cracking; - spalling; - disintegration. Although each of the basic symptoms is readily differentiated from the others, each occurs in several forms, each having a different significance. A great number of models describing the continuum behavior, phase transitions in them, criteria of ice body destruction and fragmentation under the load as well as the continual destruction models are known. 19 Internal factors affecting corrosion • Cement composition: The cement provides protection to the reinforcing steel by maintaining a high pH. • Impurities in aggregates: Aggregates containing chloride salts cause serious corrosion problems, particularly those associated with seawater. • Impurities in mixing and curing water: Mixing and curing water, either contaminated with sufficient quantity of chloride or being highly acidified due to any undesirable substance present in water, may cause corrosion. • Admixtures: Addition of calcium chloride in concrete, as a common admixture for accelerating the hydration of cement is perhaps the most significant reason for the presence of chloride. • w/c ratio: Low w/c ratio decreases the concrete permeability, which in turn reduces the chloride penetration, carbonation and oxygen diffusion. 20 Internal factors affecting corrosion • Cement content have a significant effect on durability due to formation of honeycombs and other surface defects. Its help in the penetration and diffusion of gas. • Aggregate size and grading: for a given w/c ratio, the coefficient of permeability of concrete increases considerably with increasing size of aggregates. • Proportion of coarse and fine aggregates is important for the production of a durable concrete. • Construction practices: 1) aggregate washing for deleterious materials, if any; 2) control of chloride:water, cement, aggregate, and admixtures; 3) strict enforcement of designed and recommended levels of w/c ratio, cement content, cover thickness, etc.; 4) proper consolidation of freshly placed concrete; 5) proper curing of concrete. 21 Internal factors affecting corrosion • Cover over reinforcing steel: Cover depth has a significant effect in case of corrosion due to penetration of either chloride or carbonation. • Chemical composition and structure of the reinforcing steel: The differences in the composition and structure create different potentials at different locations on the surface of reinforcement, causing the formation of differential corrosion cells. • pH of the concrete porewater: the high alkalinity of the concrete porewater results in a passive film on steel. The gases form a carbonated zone, which gradually penetrates into exposed concrete, reducing the pH. • Carbonation is characterised by a pH up to 4 describing the real corrosiveness of the concrete pore solution. 22 Internal factors affecting corrosion • Cover over reinforcing steel: Cover depth has a significant effect due to penetration of either chloride or carbonation. This effect of cover is limited within the time of casting to the time at which the reinforcement is depassivated and corrosion is initiated. • Chemical composition and structure of the reinforcing steel: The differences in the chemical composition and structure of reinforcing steel and presence of stress in the reinforcement, either static or cyclic, create different potentials at different locations on the surface of reinforcement, causing the formation of differential corrosion cells, which leads to its corrosion. • pH of the concrete porewater: In reinforced concrete structures steel is protected against corrosion by the high alkalinity of the concrete porewater resulting in a passive film on steel. The agressive gases reacts with the alkaline constituents of the cement paste to form a carbonated zone, reducing the pH of the affected region to a value where 23 corrosion will occur. 24 2. CHLORIDE INGRESSION 25 The influence of chloride aggression on the durability of concrete In the study of the penetration of chlorine in concrete two main steps can be identified: - 3 principal chloride transport models can be distinguished: a) diffusion - movement of ions under the influence of a concentration gradient; b) convection - the movement of ions and fluid flow; c) movement of ions under the influence of an external electric field. - securing the chlorine ions in the cement stone. Steel reinforcement in concrete is protected from corrosion passivation thin film consisting of oxides of iron, which is formed on the surface of the valve due to the strongly alkaline environment of concrete pore water. Depassivation of the steel reinforcement occurs in the presence of a particular chlorides, the so-called threshold or critical content. The negative impact of chlorides in concrete contrasted self-healing passivation film. The influence of chloride aggression on the durability The traditional assumption has been that chloride ingress into concrete obeys Fick's 2nd law of diffusion for a semi-finite medium with constant exposure, and that there is a critical value of the chloride content in the concrete. The aim is to develop prediction method taking into account climatic conditions of Sakhalin. The effect of the environment is represented in the parameter Cs in Fick’s law which identifies the representative chloride concentration at the concrete surface during the time of exposure. It depends on the water salinity, possibly porosity of the surface layer (amount of saline pore water) and the length of wetting versus drying in the splash zone. DuraCrete model is considered only diffusion, excluding convection. The magnitude of the convection zone is 2-10 mm, at a greater depth the main transport mechanism is diffusion. Therefore, to assess the content of chlorides in the reinforcement of occurrence depth (40 mm or more) can be applied DuraCrete model. Chloride forms in concrete Chlorides from the environment can diffuse into concrete as a result of: - the sea spray and seawater wetting; - the deicing salts; - the use of chemicals (berth, storage, brine tanks etc.) In concrete chloride may be present in any of the following forms: • Acid soluble chloride which is equal to the total amount of chloride present in the concrete or that is soluble in nitric acid; • Bound chloride which is the sum of chemically bound chloride with hydration products of the cement, such as the C3A (tricalcium aluminate) or C4AF (tetracalcium aluminoferrite) phases, and loosely bound chloride with C-S-H gel; • Free or water-soluble chloride which is the concentration of free chloride ions Cl- within the pore solution. 28 Chloride concentration The following equation shows the relationship between the chloride concentrations present (HETEK-53, 1996): cTOTAL = cFREE + cBOUND where c is the concentration in [kg/m3], [moles/volume] or [kg/kg]. The free chlorides are usually given per volume of solute, i.e. [kg/m3 solution]. The bound, and total amount of chlorides, however, are often given per weight of binder or concrete. The chloride critical level, required for corrosion, can be defined as: • total chloride content by weight of concrete; • total chloride content by weight of binder; • free (water soluble) chloride concentration in the pore solution; • ratio between the free chloride and the free hydroxide concentration. A value of 0.4 % by weight of cement is critical (Bamforth, 1999). 29 Chloride concentration For given structure it depends on: • w/c ratio; cement type; pH of the pore solution; • capacity of the cement paste to bind the chloride ions; • the exposure conditions - are “cast-in” or ingressing from an external source ; • measurement difficulties (e.g. free chloride and hydroxide); • local variations in chloride concentration at the reinforcement. 30 Chloride concentration determination • Concrete pH varies with the type of cement and concrete mix. A tiny pH change represents a massive change in hydroxyl ion (OH-) concentration. • Chlorides can be bound chemically (by aluminates in the concrete) and physically (by adsorption on the pore walls). Sulphate resisting cements have low aluminate (C3A) content which leads to more rapid diffusion and lower chloride thresholds. • In very dry concrete corrosion may not occur even at very high Clconcentration as the water is missing. • In sealed or polymer impregnated concrete, corrosion may not occur even at a very high Cl- concentration if no oxygen or moisture is present to fuel the corrosion reaction. • Corrosion can be suppressed when there is total water saturation due to oxygen starvation, but if some oxygen gets in, then the pitting corrosion can occur. 31 Chloride induced reinforcement corrosion The damage process and service life is normally modelled as an initiation and a propagation period (Tuutti, 1982) according to the two main processes. First there is a transport period until critical chloride content or sufficiently carbonated material is reached at the steel surface. The subsequent probability of deterioration is determined mainly by corrosion parameters which in turn rely on transport parameters (moisture, oxygen, chlorides, etc.) and fracture parameters. For this particular case the Tuutti’s general service life model is extended into three phases; initiation, degradation of zinc coating and finally corrosion of the steel bar. 32 33 Four factors Deterioration process includes: • Abrasion • Diffusion • Chemical reactions • Transition etc. Main factors: 1 - type of concrete, 2 - cover depth to reinforcement, 3 - site practice, 4 - severity of exposure. Interaction between many forms of deterioration is to accelerate degradation accounting for its superposition. We input the interaction coefficients and coupled degree of degradation equations. Use of calibrated computer simulations and service life models is proposed. 34 Cl- ingress Chloride penetration into concrete determines the time to depassivation initiation of localized corrosion and is thus one of the most decisive processes for durability and service life of reinforced concrete structures. Water and chlorides are transported rapidly into concrete by capillary suction. Besides the dominating influence of concrete porosity and pore size distribution the rate and amount of chloride ingress are related to the humidity gradients present in the concrete matrix as well as to the chemical properties of the hardened cement. Usage of cements with high C3A (3CaO·Al2O3) content is considered to be conducive to good resistance to corrosion because of its ability to bind chlorides chemically by forming calcium chloro-aluminate, 3CaO·Al2O3·CaCl2·10H2O, sometimes referred to as Friedel's salt. 35 However, sulphate attack from seawater results in a decomposition of calcium chloro-aluminate, thus setting chlorides free by formation of calcium sulpho-aluminate (Neville 1995). Chlorides become therefore again available for the corrosion process. Carbonation of hardened cement paste in which bound chlorides are present has a similar effect on setting free the bound chlorides and thus increasing the risk of corrosion. It has been found that the presence of even a small amount of chloride ions in carbonated concrete enhances the rate of corrosion induced by low alkalinity of carbonated concrete (Glass et al., 1991). Whereas active corrosion of the reinforcing steel bars can be detected in the laboratory and onsite by non-destructive electrochemical techniques as potential measurements, no such possibility exists for the detection and quantification of chloride ions in concrete. Only qualitative information on chloride distribution can be obtained from potential mapping. 36 LIST OF ION TRANSPORT PROCESSES Pressure-induced water flow due to the application of a hydrostatic head. A water permeability coefficient has been learned more detailed than any other. Water absorption is the uptake of water resulting from capillary forces, characterized by a sorptivity coefficient. In environments where significant concrete drying is possible, water absorption may lead to very rapid penetration of species dissolved in the water. E.g. concrete in the splash zone of marine structure or bridge elements under deicing salts attacks have rapid chloride ion ingress due to water absorption. Water vapour diffusion is the diffusion of water as a vapour, characterized by a water vapour diffusivity coefficient. This is the process by which concrete dries and it controls the moisture distribution in a concrete element after a period of drying. 37 LIST OF ION TRANSPORT PROCESSES Wick action is a combination of water absorption and water vapour diffusion, characterized by sorptivity and water vapour diffusivity coefficients respectively. Wick action is the transport of water from the wetted face of a concrete element to a drying face. Species dissolved in the water are transported to the zone of the element where drying occurs and may result in salt crystallization. Ion diffusion is the movement of ions as a result of a concentration gradient, characterized by an ion diffusion coefficient. Ion diffusion is only significant where the concrete is nearly or completely water saturated. The ions that are usually of most interest are chlorides and sulphates. Compared with most other transport processes, ion diffusion is very slow, but is often rapid enough to cause deterioration well within the design life of a concrete structure. 38 LIST OF ION TRANSPORT PROCESSES Gas diffusion is the movement of gas molecules as a result of a concentration gradient, characterized by a gas diffusion coefficient. Diffusion of carbon dioxide into concrete results in carbonation. In some situations, diffusion of oxygen controls the rate of corrosion of steel in concrete. Pressure-induced gas flow is the flow of gas due to a pressure gradient, characterized by a gas permeability coefficient. Gas permeability is relatively easy to measure, but is not relevant to the behaviour of the vast majority of concrete structures. 39 Chloride ion penetration The transport and distribution of chlorides in a concrete structure is very much a function of the environmental conditions, mainly the concentration and duration of the solutions in contact with the concrete surface. The conditions are quite different in different exposure situations. Below the level of sea water, the concentration of chlorides is more or less constant with time. The penetration is a pure diffusion process at constant boundary conditions. At early ages, however, a negative pressure (suction) is produced as the hydration of cement takes place in the interior parts of the concrete (Gonzalez, Jalali 2004). Most other cases of exposure situations have boundary conditions that change according to a more or less rapid and complicated relationship with time. 40 Chloride ion penetration In the splash zone above sea water level, salt water is sucked into the concrete surface. Rain water washes the surface free from chlorides and may remove some of them. Evaporation increases the concentration. Chlorides move inwards and outwards due to moisture flow and ion diffusion. The distribution of chlorides, i.e. concentrations at different depths, is a time-dependent function of the environmental conditions, the design of the structure and the material properties. The mechanisms of chloride transport and binding involved are complex and usually combined in a complex way. Chloride binding in concrete is important since the binding process removes chloride ions from the concrete pore solution into the solid hydrated binder phase. The processes are not always understood and still not easy to quantify. 41 Chloride ion penetration • The environmental data are atmospheric temperature, humidity, air-borne chloride content and wind speed. • The evaluation of chloride/carbonation profiles must be incorporated. This investigation helps to statistically characterise the diffusive property of concrete and evaluate the distribution of surface chloride concentration. • The every project is unique and precise characteristic of the design are quantified by testing the material used at site. • The measurements of concrete cover thickness may done using ground penetrating radar, electromagnetic test, ultrasonic and radiography. • The chloride diffusion coefficients are measured on structural concretes under standard conditions by rapid migration method. The concrete surface chlorides and airbourne chlorides are obtained. • The critical threshold chloride concentration is evaluated by the accelerated chloride threshold testing. Additions of admixtures such as ground granulated blast furnace slag, fly ash, silica fume and metakaolin alter the properties of ordinary portland cement concrete. 42 Type of concrete Predictions of durability are difficult to make given the complexity of deleterious physical and chemical interactions depending on seawater, concrete and structure parameters. The physical properties of concrete control it transport properties but ignoring chemical effects. Chloride ingress into concrete is not only determined by the permeability of the pore system but also by interactions between the concrete and the diffusant that depletes the concentration and constricts the pore structure. Concrete containing fly ash and slag have good chloride binding characteristics with high chloride resistance. 43 Result of chloride ingression – CORROSION OF REINFORCEMENT External factors affecting corrosion : • oxygen and moisture at reinforcement level; • relative humidity; • temperature; • carbonation and penetration of acidic gaseous pollutants to the reinforcement level; • aggressive anions reaching the reinforcement level; • biocorrosion; • Concrete quality: - w/c ratio; - cement composition; - impurities in aggregates; - impurities in mixing and curing water; - admixtures (calcium chloride etc); 44 CHLORIDE ION MIGRATION Chloride ions act as catalysts in the disruption of the passive ferric oxide layer and are recycled for use elsewhere along the steel surface. A minimum concentration of chlorides at the steel, known as the corrosion threshold level, is required to depassivate reinforcement under normal alkaline conditions. 45 Corrosion due to Cl- ions Chloride ions present in the cement paste surrounding the reinforcement react at anodic sites to form hydrochloric acid which destroys the passive film. The surface of the steel form the anode, and the passive surface – cathode. It is the corrosion in the form of localized pitting. 46 - cement content; - aggregate size and grading; - construction practices; - cover over reinforcing steel; - chemical composition and structure of the reinforcing steel; - pH of the concrete porewater. The corrosion rate is dependent on if the reinforcement corrosion has been initiated by chloride ingress or carbonation. In extreme cases the corrosion rate can be up to 5 mm/year for corrosion initiated by chloride ingress and 0.05 mm/year for carbonationinitiated corrosion. Corrosion have two primary forms: cracking and spalling of cover concrete due to the formation of expansive corrosion products at the reinforcement. Corrosion of steel in concrete depends on pH of the pore solution, temperature, internal stresses, stray currents and electrolytic potentials. 47 Result of carbonation – CONCRETE INTEGRITY DESTRUCTION Carbon dioxide and the chloride ion penetrate the concrete without significantly damaging it. The aggressive chemical species pass through the pores in the concrete and attack the steel. Other acids and aggressive ions such as sulphate destroy the integrity of the concrete before the steel is affected. The chemical elements attack the concrete. 48 3. LAWS FOR CHLORIDE INGRESSION 49 • The simulation of transfer phenomena in porous cement composites to assess long-term safety and reliability of mechanical characteristics of concrete in extreme conditions. • Approach 1 focuses on the development of a generalized model of the "Hydration-Transport" (GT), which explicitly takes into account the impact of the porous microstructure, nano, interfacial transition zones (MPZ) and micro / MacroTrap-women on the moisture diffusion and transport phenomena. • Approach 2 focuses on mechanical degradation model (GTM) of concrete, which is exposed in chloride concentration from the sea or other sources and, in particular, on the impact of these processes on long-term service life. Multiscale modeling of fracture process of concrete to simulate the mass transport of ions and / chlorides is necessary data on natural conditions (metocean), the results of the surveys. Analysis is based on hydration model of cement, microporous model, the equation of equilibrium of the moisture transport model. 50 Mathematical implementation Due to the stochastic nature of the parameters that govern the performance of concrete structures, a probabilistic approach is needed to generate reliable service life predictions. IImprovements to the basic of Fick`s 2nd Law include the time dependency of the model, and the temperature effect on the diffusion coefficient. Some of the models advantages are the ability to use different diffusion coefficients obtained either from the Rapid Chloride Migration and the Chloride Profile Method, the evaluation of the chloride profiles and the determination of the surface concentration of chlorides as well as the diffusion coefficient based on the best fit curve of the profile by Fick’s 2nd law and the prediction of future chloride profiles based on present profiles. From a probabilistic point of view, the use of several distribution types and the incorporation of a variable to account for model variability are also advantages. 51 Fick’s law assumes that the ions move independently of each other (uncharged particles) and that the interaction with the matrix system is very weakly or non exist. However, ions move in strong electrostatic fields created by all the charged particles in the matrix. Many of the ions interact very strongly with the negative charged hydration products. Therefore, the diffusivity of the chloride ions in concrete does not follow Fick’s law adequately, particularly in high density concrete with a fine pore structure 52 Laws of diffusion of Cl- ions The traditional assumption has been that chloride ingress into concrete obeys Fick's 2nd law of diffusion for a semi-finite medium with constant exposure, and that there is a critical value of the chloride content in the concrete. The aim is to develop prediction method taking into account climatic conditions of Sakhalin. The effect of the environment is represented in the parameter Cs in Fick’s law which identifies the representative chloride concentration at the concrete surface during the time of exposure. It depends on the water salinity, possibly porosity of the surface layer (amount of saline pore water) and the length of wetting versus drying in the splash zone. x Cx Csn 1 erf 2 Da t t , Corrosion deterioration model The design model for chloride-induced corrosion is adapted from the analytical model of diffusion. With the DLS specified as the corrosion initiation state (a), the design equation G = Cth − C(Cs, xd, Dc, TSL) (1) The objective being to obtain cover thickness (xd) and specifications of the concrete such as the chloride diffusion coefficient of concrete (Dc) for the specified design life (e.g.TSL=80 years) C is the chloride concentration function in concrete. The governing parameters: • Threshold chloride concentration (Cth) • Concrete surface chloride concentration (Cs) • Chloride diffusion coefficient of concrete (Dc) • Concrete cover thickness (xd) 54 Chloride penetration models Model Dura Crete Mejlbro-Poulsen ClinConc MsDif Chloride concentration Service life design 56 Service life - model Tuutti (1982) 57 Tuuttii model Once the steel is effectively depassivated, the corrosion rate and subsequent damage will depend on micro-effects such as availability of oxygen and moisture and macro-effects such as structural geometry, anode/cathode ratios and general ambient conditions. Chloride ions act as catalysts in the disruption of the passive ferric oxide layer and are recycled for use elsewhere along the steel surface. Once the steel is effectively depassivated, the corrosion rate and subsequent damage will depend on micro-effects such as availability of oxygen and moisture and macro-effects such as structural geometry, anode/cathode ratios and general ambient conditions. Tuutti model ( 1982) describes the two processes. 1 - transport of ions until critical chloride concentration or sufficiently carbonated material is reached at the steel surface. The subsequent probability of deterioration is determined mainly by corrosion parameters 58 Tuuttii model Equation yields for chloride induced reinforcement corrosion of hot dipped galvanised reinforcing steel in concrete (Sistonen et al., 2006). 59 Fick’s Second Law A durability model for the reinforcement corrosion, based on the second Law of Fick, is developed that takes into account the time dependent parameter for diffusion coefficient and the influence of temperature. The existing models are either difficult to use due to the complexity of calculations, and the fact that they require sophisticated tests for collecting the necessary data, or are too simplistic to provide reliable results. The proposed model requires few basic data, either available or easily obtainable, without compromising its scientific robustness and validity. 60 Fick’s law - diffusion model for transport mechanism In the 1970’s Fick’s laws were introduced by Collepardi (1970) for describing the ingress of chlorides into concrete. The diffusion of chloride in concrete can be expressed by means of the ionic flow J, which is by definition positive, if the chlorides move in positive x-direction. If the concentration decreases in x-direction the flow is negative where J - ionic flow, kg/m²s; D - diffusion coefficient, m²/s; c - chloride concentration in solution, kg/m³; x - distance, m. 61 Fick’s law - diffusion model for transport mechanism Fick’s first law of diffusion. However, time dependency was not taken into account. To describe the diffusion process, the particle density must be function of space and time. Starting with Fick’s 1st law and considering the law of mass conservation, Fick’s second law is obtained. The application of Fick’s laws of diffusion to describe the transport processes in concrete is based on the simplified assumption that concrete 62 is homogeneous, isotropic and inert (Tang 1996). The main problem with using Fick´s second law is that the chloride ions interact with the concrete and that diffusion is not the only transport mechanism working. The movement of negatively charged ions induces the movement of positively charged ions. The sodium and chloride move at different velocity (Tang 1996). Fick’s law - diffusion model for transport mechanism But model gave unrealistic rapid transport of chloride ions because of constant diffusion coefficient (Cairns et al 2003). Fick’s law assumes that the ions move independently of each other (uncharged particles) and that the interaction with the matrix system is very weakly or non existent. However, ions move in strong electrostatic fields created by all the charged particles in the matrix. Many of the ions interact very strongly with the negative charged hydration products. Therefore, the diffusivity of the chloride ions in concrete does not follow Fick’s law adequately, particularly in high density concrete with a fine pore structure. 63 Fick’s law - diffusion model for transport mechanism Takewaka et al. (1988) proposed to describe diffusion coefficient as a power function of time. 64 The α exponent reflects the decrease of the diffusion coefficient with age due to the combined effect of hydration and all other mechanisms as ion exchange with seawater. Thus α=β+γ, where β - effect of hydration of the cement, γ - effect on the concrete skin by being in contact with the seawater. They are obtained from laboratory or field tests. Predicted chloride profiles (3 variants) in concrete cover Cl- change near steel bars and reliability index during service life accounting for repairs DuraCrete model In DuraCrete (1997) three different types of service lives are defined: • Technical service life: The technical service life is the time in service until a defined unacceptable state of deterioration is reached; • Functional service life: The functional service life is the time in service until the functional performance of the structure becomes obsolete, due to changed requirements from e.g. authorities or the owner; • Economic service life: The economic service life is the time in service until it is economically interesting to replace the structure than to maintain it. 67 DuraCrete model is considered only diffusion, excluding convection. The magnitude of the convection zone is 2-10 mm, at a greater depth the main transport mechanism is diffusion. Therefore, to assess the content of chlorides in the reinforcement of occurrence depth (40 mm or more) can be applied DuraCrete model. The model is based largely on observations of penetration of chlorides in actual construction, which reduces the need for verification. DuraCrete model also takes into account the decreasing diffusivity of concrete with age. The task - to measure the potential properties of the materials in the laboratory, to adapt them to the actual conditions and use them in the calculation of chloride penetration in natural conditions. DURACRETE MODEL As can be seen from the equations DuraCrete model uses three factors, taking into account the environmental effects (Table 1). Table 1: The parameters of DuraCrete model Parameter Description kC,T factor that accounts for the influence of temperature on the chloride content of the surface kD,RH factor which takes into account external conditions, in particular, the influence on the PH chlorides diffusion coefficient kD,T factor which takes into account external conditions, in particular, the influence of T on the diffusion coefficient of chlorides 4. CAPILLARY-POROUS MICROSTRUCTURE 70 Three parameters are important in modeling chlorine penetration in concrete: 1) concrete permeability; 2) concentration of chlorine; 3) chlorine threshold value as a function of time. The water transport is possible only in keeping with the mechanism of molecular diffusion. Micro-capillaries cause capillary condensation. Three main types of pores are built up in the cement stone: 1) the pores of cement gel; 2) capillary pores; 3) conventionally closed pores. The water in the pores of gel does not freeze when the concrete and reinforced concrete frames are in operation, and it can be explained by their size and the presence of electrolytes in the pore fluid. Capillary pores can be presented as the part of water volume of the cement-water paste which is not filled with cement hydration products. 71 FORCES IN CAPILLARY PORES (study of prof. Leonovich and Kim) The liquid in a capillary tube is kept by forces of surface tension, which magnitude is determined under the formula Pc ac cos where is surface tension of a liquid; is angle of wetting or boundary angle on the boundary "a liquid is wall of a capillary tube"; ac is diameter of a capillary tube. CAPILLARY PORES 5. FEFU modeling of solution transport in concrete cover zone and chloride profiles 78 79 Destruction under water tensile stress These water movements locally generate internal pressures, which may, eventually, exceed the tensile strength of concrete (Helmuth, 1961). Investigations on the subject show how degradation is linked to the degree of saturation of the material (Bager, et al., 1986; Fagerlund, 1971; Marchand, et al., 1995). Frost damage typically occurs in the form of cracking and/or surface scaling. The basic facts of frost durability remain that air-voids work as protection, that the damage is linked to the material degree of saturation and access to water during freeze/thaw due to the freeze/thaw pumping effect and that concrete with sufficiently low water/binder ratio and high strength can be made frost durable even without air entrainment. 80 Destruction The influence could well be on the capillary pore system (effect on freezable water, ice formation in pores and water movements) or on the microstructure of the surface layer (resistance as a function of type and quantity of hydrates and of air voids). The composition of the concrete mixture can also have a combined effect by modifying the sensitivity of concrete to other parameters. Several mechanisms have been proposed to explain salt scaling degradation. Most of them rely on pressures developed related to the ice formation in the pore system (Marchand, et al., 1994; Pigeon, et al., 1996a). According to these theories, damage does result from pressures exerted by the ice on pore walls or by hydraulic and osmotic pressures developed by the expulsion of water during the growth of ice in the pore system. Others suggest that pressures could be due to the crystallization of salts or expansive products in the pore system. Valenza and Scherer proposed a new mechanism that accounts for several experimental observations (Valenza and Scherer, 2005). 81 Ice abrasion The “glue-spall” mechanism explains the “pessimum” salt concentration of around 3% and why the scaled material consists of thin flakes. The ice layer that would penetrate the concrete surface and bifurcate in such a way as to remove small flakes of mortar. During cooling, salt in the outer solution would create brine pockets in the ice that would act as flaws. The “pessimum” concentration of salt in the outer solution is explained by the fact that pure water ice is too strong to crack and at higher concentrations, the ice/brine mixture is not rigid enough to develop stresses. 82 Mathematical implementation Due to the stochastic nature of the parameters that govern the performance of concrete structures, a probabilistic approach is needed to generate reliable service life predictions. IImprovements to the basic of Fick`s 2nd Law include the time dependency of the model, and the temperature effect on the diffusion coefficient. Some of the models advantages are the ability to use different diffusion coefficients obtained either from the Rapid Chloride Migration and the Chloride Profile Method, the evaluation of the chloride profiles and the determination of the surface concentration of chlorides as well as the diffusion coefficient based on the best fit curve of the profile by Fick’s 2nd law and the prediction of future chloride profiles based on present profiles. From a probabilistic point of view, the use of several distribution types and the incorporation of a variable to account for model variability are also advantages. 83 • The simulation of transfer phenomena in porous cement composites to assess long-term safety and reliability of mechanical characteristics of concrete in extreme conditions. • Approach 1 focuses on the development of a generalized model of the "Hydration-Transport" (GT), which explicitly takes into account the impact of the porous microstructure, nano, interfacial transition zones (MPZ) and micro / MacroTrap-women on the moisture diffusion and transport phenomena. • Approach 2 focuses on mechanical degradation model (GTM) of concrete, which is exposed in chloride concentration from the sea or other sources and, in particular, on the impact of these processes on long-term service life. Multiscale modeling of fracture process of concrete to simulate the mass transport of ions and / chlorides is necessary data on natural conditions (metocean), the results of the surveys. Analysis is based on hydration model of cement, microporous model, the equation of equilibrium of the moisture transport model. 84 Capillar-porous concrete model Concrete is a quasi-brittle porous material (Bazant, et al., 1998). Under usual exposure conditions, its pore structure is partially (or even fully) saturated with an aqueous solution. If the ambient temperature is reduced below the freezing point of the aqueous solution, ice will progressively form in the saturated pores. The ice formation process is directly affected by the pore size distribution of the material (Helmuth, 1960; Zuber and Marchand, 2000). This partial solidification of the pore solution will often force the remaining unfrozen water to move. Depending on the temperature history, unfrozen water can either be expelled from the freezing sites or attracted to the ice crystals formed within 85 the material’s pore structure (Powers, 1949; Powers, et al., 1953). Hydrodynamic model of ion transport Object is concrete cover. The concrete is considered as complex of solid round particles with porous cement paste. The reinforcement bar is round solid body too. The problem is plane 2D. The contact and surface problems of chloride distribution are complex and inherently non-linear due to the moving boundary and the different properties along the contact surfaces. The size of the contact areas and the contact pressure depend on geometry of the ice feature and the structure and changes during the interaction process. The aim is the development of theory and numerical techniques for the determination of kinematic field on the base of consistency between constitutive equations and solution trajectories (or flow lines). These lines are considered as “conditional” capillaries. The nearest analogous method is the Strain Path Method of M. Baligh (J of Geotechnical Engg ASCE, V. 111, GT9, 1985. 11081136). The fixed velocity field of ice features is calculated using theorem of velocity summation. 86 Capillary diffusion flow lines of solution transport Absolute system Relative system Concrete surface Chloride profile Capillary lines Bar 87 Chloride profile simulation at convection process 88 Test chloride profiles 89 3 years existing 5 years Chloride reaches threshold at cover of 60mm in 13 years Cl- profile during construction For construction work in marine environment, recent experience has also shown that a high chloride penetration may take place already during the construction period before the concrete has reached sufficient maturity and density. 91 Cl- profile for harbour concrete vs exposure period 92 Cl- profile for marine high-performance concrete 93 Cl- profile vs underwater levels 94 Cl- profile vs coating 95 Chloride profiles for marine and road concretes (Nilsson et al, 2000, Tang, 2003 96 FEFU tests in port Kholmsk (different marine structures), 2018 2 – pile of bridge; 3 – berth 50 years; 4 - Japaneese berth 70 years; 6 – superstructure of berth 97 1 - Convection zone 2 – Diffusion zone 98 Convection and diffusion zones Sandberg (1998) Nilsson et al (2000) 99 Predicted chloride profiles from different models 100 101 Chloride profile equation 102 Models are divided into three groups: 1) kinematic (Lighthill-Whitman); 2) models of 2nd order; 3) models on the base of kinetic equations. Kinematic (hydrodynamic) models are based on mean terms such as concentration, velocity, flow etc. Kinetic (gas dynamic) models consider density in phase space. The surface of shaft is divided on several areas : compression, stick-slip, sliding and back. The main assumptions are: 1) fixed velocity field is calculated using theorem of velocity summation; 2) contact normal and tangential stresses are calculated using the resultant velocity field. 103 104 105 106 107 108 109 110 CONCLUSIONS The interaction between forms of damage is to accelerate degradation. Degree of degradation is based on superposition of degree of degradation with interaction coefficients and coupled degree of degradation equations. Material data and observations of rate of degradation under several types of deterioration in field and/or in accelerated laboratory tests can be used to determine the coupling coefficients. The deterioration has a significant impact on the strength of the structure but only in the splash zone, where under the influence of sea level variations. More important to assess the quality of concrete during fdurability tests. It is clear that, in order to improve the accuracy of the predictions of the service life of reinforced concrete structures, a performance based methodology should be adopted associated with probabilistic methods. By using probabilistic methods, it is possible to take into consideration the variations of material properties, the environmental loading and the effect of the quality of execution during construction. Future directions of research 1. To define the joint diffusion mechanical model for road concrete on the base of microporous model for water diffuse transport (“transport model”), depending on the capillar way net, porosity of the cement stone and matrix of pore bond properties. 3. To develop the model of concrete damage based on the criteria of specific destruction energy obtaining from tests. 4. To represent the deteriorations of concrete on the base of FEM for multiscale analysis of the diffusion process in the concrete. 5. To study nanodimensional and microporous structures on hydration of concrete using the Delft Hymostruc software. 6. To develop the analysis method of concrete service lifetime prediction for specific operation conditions. Main publications of author Kim L.V., Shaly E.E. Capillary-Porous Effects in Concrete during Ice Abrasion // Solid State Phenomena, September 2017, London. Trans Tech Publications. Kim L.V., Leonovich S.N. Offshore concrete structures in cold region // Proc Int Symposium on Okhotsk Sea & Sea Ice, February 21-23 2016, Mombetsu, Japan. 6 p. Kim, L.V. et al. Increase of concrete strength using nanosilica extracted from the hydrothermal solutions. Proc Int Offshore and Polar Engineering Conference (ISOPE), 2013. P. 148-152. Kolomiets, V. I., Kim, L. V. Frost resistance and abrasion resistance of concrete gravity bases of oil and gas platforms. J Building materials, 7, Moscow, 2007. in Russian. Bekker, A. T., Jacobsen, S., Uvarova, T. E., Pomnikov, E. E, Kim, L. V. (2011). Evaluation of danger from ice abrasion of offshore platforms in Far Eastern seas. Proc RAO/CIS Offshore conference, St-Petersburg, 262-265. Leonovich S.N., Shalyi E.E., Falaleeva N.A., Kim L.V. The influence of carbon dioxide on the durability of offshore concrete structures // Proc Int Ocean and Polar Engineering Conference, Rhodos, Greece, 26.06-02.07.2016. Leonovich S.N., Shalyi E.E., Kim L.V. et al. Chloride ingression of concrete embankments // Proc IACGE Int Symposium on Geotechnical and Earthquake Engineering, 11-15.10.2016, Beijin. Leonovich S.N., Kim L.V. Frost resistance of marine concrete structures // Proc 11th Int Symposium in Cold Region Development (ISCORD), May 18-20 2016, Incheon, Korea. Leonovich S.N., Shalyi E.E., Kim L.V., Dzhogolyuk A.G. Degradation of Marine Reinforced Concrete Berth Structures on Sakhalin Island // Proc 27th Int Ocean and Polar Engineering Conference, San Francisco, USA, June 25-30 2017. 124-127. 113 Main publications of author Jacobsen, S., Kim, L.V., Pomnikov, E.E. Concrete destructure due to ice-indentation pore pressure. Proc Int Offshore and Polar Engineering Conference (ISOPE), 2013. P. 1258-1263. Bekker, A.T., Kovalenko, R.G., Luybimov, V.S., Kim, L.V. Steel constructions corrosion wear processes modeling of sea hydraulic engineering structures. Proc Int Offshore and Polar Engineering Conference (ISOPE), 2011. P. 319-326. Kovalenko, R.G., Kim, L.V. Durability evaluation of marine and offshore structures. Proc Int Offshore and Polar Engineering Conference (ISOPE), 2009. P. 233-239. Tsuprik V.G., Zanegin V.G., Kim L.V. Mathematical Modelling of Ice-Structure Interaction // IOP Conference Series: Earth and Environmental Science, 2019. 272. 022063. DOI 10.1088/1755-1315/272/2/022063. Falaleeva, N.A., Tyitrin, R.S., Kim, L.V., Seliverstov, V.I. Corrosive resistant of slag concrete with volcanic rock for offshore conditions. Proc Int Offshore and Polar Engineering Conference, 2015. P. 105-106. Falaleeva, N.A., Tyitrin, R.S., Kim, L.V. Marine concrete from granulated phosphorite slag cement. Proc 11th Pacific/Asia Offshore Mechanics Symposium (PACOMS), 2014. P. 96-99. Kim L.V. Cognitive maps for structural reliability control. Proc Int Offshore and Polar Engineering Conference (ISOPE), 2008. P. 434-441. Leonovich S.N., Chernyakevich O.Y., Kim L.V. Carbonation of reinforced concrete sytructures : monography. Vladivostok, FEFU, 2018. 61 p. Leonovich S.N., Stepanova A.V., Tsuprik V.G., Kim L.V., Gurinovich V.Y. Durability of concrete under chloride ingression : monography. Vladivostok, FEFU, 2020. 100 p. 11 patents of Russia, 13 handbooks for students. 114 REFERENCES to presentation Arup H. The Study of Transportation Mechanisms Using Migration Experiments. Some Caveats and Ideas for Future Research. Nordic Miniseminar: Chloride Penetration into Concrete Structures. January 1993, Goteborg. DuraCrete. Modelling of Degradation. Probabilistic Performance-based Durability Design of Concrete Structures. EU-Project Brite EuRam III No BE95-1347, Rept 4-5, 1998. Jacobsen, S., Sellevold, E. J. Sæther, D. H. Frost testing high strength concrete: frost/salt scaling at different cooling rates. RILEM/Materiaux et Constructions, V. 30, 195, 1997. P. 33– 42. Maage, M., Poulsen, E., Vennesland, O. & Carlsen, J.E. Service Life Model for Concrete Structure Exposed to Marine Environment – Initiation Period. LIGHTCON Report 2.4, STF70 A94082. SINTEF, Trondheim, 1995. Fagerlund, G. Synergetic Effects of Combined Destructive Action on Concrete. Proc Int Symposium: Role of Concrete In Sustainable Development, 3-4 Sept. 2003, Dundee, 2003. Melchers R. E. Long-Term Durability of Marine Reinforced Concrete Structures. J Marine Science and Engineering, 2020. Mackechnie, J.R. Predictions of reinforced concrete durability in the marine environment. PhD Thesis, University of Cape Town, 1996. Mejlbro, M. The Complete Solution to Fick’s Second Law of Diffusion with Time-dependent Diffusion Coefficient and Surface Concentration. In Durability of Concrete in a Saline Environment. CEMENTNA AB. Danderyd, 1996. Sistonen E., Vesikari E. Effect of Interacted Deterioration Parameters on Service Life of Concrete Structures in Cold Environments - State of the Art. VTT-R-09217-08. 115 REFERENCES to presentation Kruschwitz, J., Bluhm, J. Modeling of ice formation in porous solids with regard to the description of frost damage. Computational Materials science, V. 32, 2, 2005. P. 407-417. Puatatsananon, W., Saouma, V. E., Nonlinear Coupling of Carbonation and Chloride Diffusion in Concrete. J Materials in Civil Engineering (ASCE)/May/June 2005. P. 264-275. Scherer, G. W. Freezing gels, J of Non-Crystalline Solids, V. 155, 1993. P. 1-25. Scherer, G. W. Crystallization in pores, Cement and Concrete Research, V. 29, 8, 1999. P. 1347-1358. Zuber, B., Marchand, J. (2000), Modeling the deterioration of hydrated cement systems exposed to frost action, Cement and Concrete Research, Vol. 30, p. 1929-1941. Zuber, B., Marchand, J. (2004), Predicting the volume instability of hydrated cement systems upon freezing using poro-mechanics and local phase equilibria, Materials and Structures/Concrete Science & Engineering, V. 37, 268. P. 257-270. Ferreira, R.M. Probality-based durability analysis of concrete structures in marine environment. Rui Miguel Ferreira. Guimaraes, Portugal, 2004. 116 Thank you for attention! 117