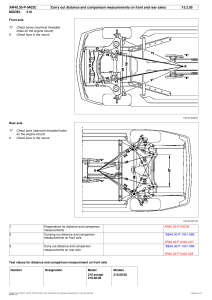

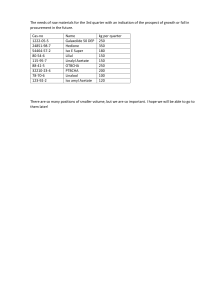

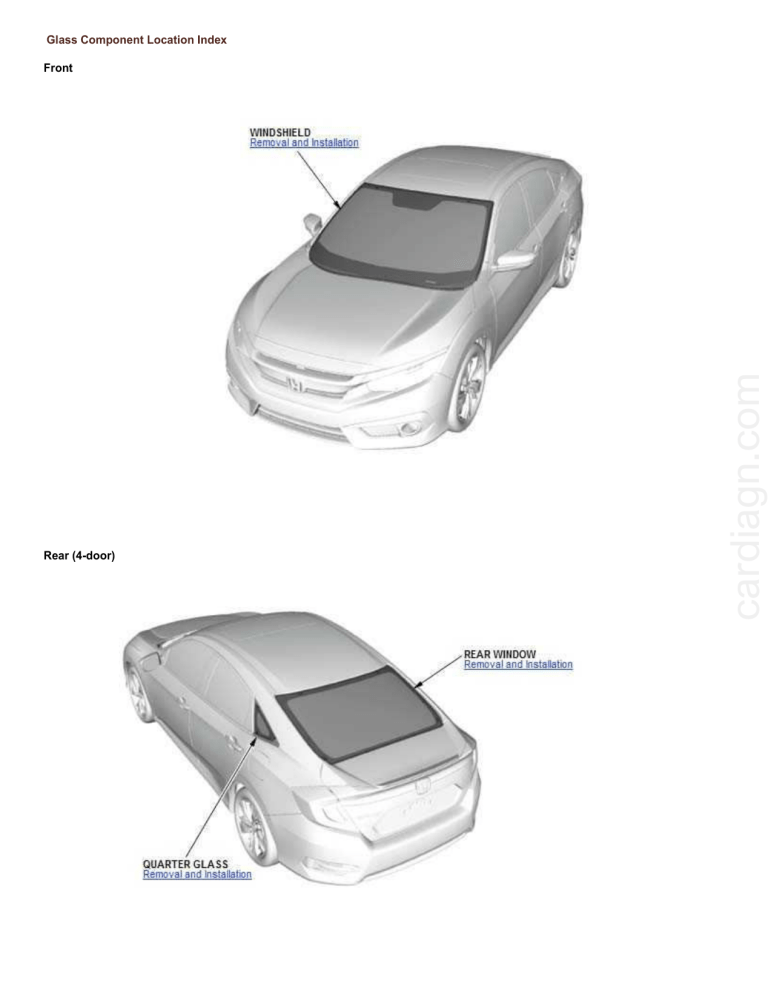

Glass Component Location Index Rear (4-door) cardiagn.com Front cardiagn.com Rear (5-door) cardiagn.com Mirrors Component Location Index Door Glass Adjustment NOTE: Check the door weatherstrip and the glass run channel for damage or deterioration, and replace them if necessary. 1. Door Panel - Remove Front door Rear door 2. Plastic Cover - Remove Front door 3. Door Glass - Adjustment Front door NOTE: Place the vehicle on a firm, level surface when adjusting the door glass. 1. Carefully lower the glass (A) until you can see the glass mounting bolts (B), then loosen them. 2. Push the glass against the glass run channel (C), then tighten the glass mounting bolts. 3. Check that the glass moves smoothly. cardiagn.com Rear door 4. Raise the glass fully, and check for gaps. Also make sure that the glass (A) contacts the glass run channel (B) evenly. 4. Plastic Cover - Install Front door Rear door 5. Door Panel - Install cardiagn.com Rear door cardiagn.com Front door Rear door 6. Power Window Control Unit - Reset 7. Water Leaks - Check Check for water leaks. Run water over the roof and on the sealing area as shown, and note these items: Use a 12 mm (0.47 in) inside diameter hose (A). Adjust the rate of water flow as shown (B). Do not use a nozzle. cardiagn.com Hold the hose about 300 mm (11.81 in) away from the door (C). Glass - Installation of Glass 1. Installation of Glass Front and rear window glass sealing has two basic functions: Prevent wind, rain, dust, noise, and outer air from entering the passenger compartment Hold the glass in position during a collision Two sealing methods are used, adhesive and weatherstrip. The glass pane is directly attached to the body with a urethane-based sealer. In order to improve the adhesive effect between the body and glass and also to heighten the rigidity of the window opening area and tightness, glass primer and body primer are applied to the glued areas. Installing this type of glass has a safety advantage because the glass is securely retained during a collision. Wind noise is also reduced through its flash surface effect. This adhesive type is used for front windshield, rear windows (including tailgate), and quarter windows (excluding an open/closing type), Weatherstrip Type: The glass is fixed in the body by being tucked into a rubber weatherstrip that is weather and solvent-proof. During glass installation, sealer is applied on the contact surface to prevent entry of dust, water, and noise. The sealer also helps prevent the glass from falling out of the weatherstrip during a collision. This adhesive type is most often used for rear and side windows of commercial vehicles such as panel vans and pick-ups. cardiagn.com Adhesive Type: Glass - Types of Glass 1. Types of Glass As the vehicle collision performance improves, requirements are increased for automobile glass as well; better visibility, improved safety from external impact, isolation of noise from the passenger compartment, and enhanced appearance. Tempered Glass: This glass is a specially processed with a high strength by heating a glass to the softening temperature about 1,202 °F (650 °C) and then evenly and quickly air-cooling the surface. Another characteristic is that it instantaneously shatters into tiny pieces when broken. A type of tempered glass. It was designed to improve the visibility problems created when normal tempered glass breaks. By reducing the level of tempering, cracking of the glass is reduced and the driver can maintain his/her visibility. Laminated Glass: Two glass panes are compressed together with a transparent, high adhesive film resin in between. As a result, even if the glass is impacted and broken by an external force, it does not separate into sharp pieces. It is most commonly used for windshields. In body repair, if the body is straightened with the glass in position, the glass may break. Other Special Types of Glasses: Types of Glass Heater printed glass Heat absorption (colored) glass Characteristics Electric conducive powders are printed in the shape of a hot wire on the surface of glasses before heat treatment. A small amount of metal such as cobalt or iron is mixed in a normal glass to color it so that it can absorb infrared rays (heat rays). Main Use Windshield and rear window All Partially shaded glass Only upper part of a glass is colored to reduce transillumination rate. The color becomes darker as it goes to the upper part and thinner as it does down to the lower part. Windshield Antenna-buried glass Antenna line for receiving radio transmission is buried in the middle layer of the laminated glass or the line is printed on the glass surface. There is also a type that has both a buried wire and printed wire. Rear window and side windows cardiagn.com Partially Tempered Glass: Mirror Holder Removal and Installation 1. Mirror Holder - Remove 1. Adjust the mirror fully to the upward position. 2. Put a shop towel in the opening between the bottom edge of the mirror holder (A) and the mirror housing (B) to prevent scratches. 4. Remove the mirror holder (A). 5. Disconnect the connectors (B). 2. All Removed Parts - Install cardiagn.com 3. Insert a flat-tip screwdriver under the mirror holder, and release the hooks (C). 1. Install the parts in the reverse order of removal. cardiagn.com NOTE: Before reinstalling the mirror holder to the inner holder (A) of the actuator, make sure the actuator rods (B) are securely mounted in the holes, and that the boots (C) properly cover each rod. Mirror Housing Cover Removal and Installation 1. Mirror Holder - Remove 2. Mirror Housing Cover - Remove cardiagn.com 1. Release the hooks (A), then remove the mirror housing upper cover (B). 2. Remove the mirror housing lower cover (A). 3. Disconnect these connectors: Connector (B) (with mirror turn) Connector (C) (with LaneWatch) 4. Remove these items: Side turn signal light (with mirror turn) LaneWatch camera (with LaneWatch) cardiagn.com Driver's side cardiagn.com Passenger's side 5. Release the retainer (A), then remove the inner holder (B). 3. All Removed Parts - Install 1. Install the parts in the reverse order of removal. 4. LaneWatch Camera - Aim (With LaneWatch) cardiagn.com 6. Remove the mirror visor (C). Quarter Glass Removal and Installation 1. B-Pillar Upper Trim - Remove 2. Quarter Pillar Trim - Remove 3. Quarter Glass - Remove 2. Remove the quarter glass front seal (A). If necessary, cut the front seal with a utility knife. cardiagn.com 1. Apply the protective tape along the inside and outside edges of the body. Make a hole with an awl through the adhesive from inside the vehicle. Push a piece of piano wire through the hole, and wrap each end around a piece of wood. 3. With a helper on the outside, pull the piano wire (A) back and forth in a sawing motion. Hold the piano wire as close to the quarter glass (B) as possible to prevent damage to the body, and carefully cut through the adhesive (C) around the entire quarter glass. 4. Carefully remove the quarter glass. 5. Scrape smooth the original adhesive with a knife until there is a thickness of about 1 mm (0.04 in) - 2 mm (0.08 in) on the bonding surface around the entire quarter glass opening flange. NOTE: Do not scrape down to the painted surface of the body; damaged paint will interfere with proper bonding. Cutting positions 1. Quarter Glass - Install cardiagn.com Remove the clips from the body. 2. Apply a light coat of the primer to the quarter glass (A) along the edge of the front seal (B) and the molding (C) as shown, then lightly wipe it off with gauze or cheesecloth. NOTE: Apply the primer to the front area (D) and the corner areas (E) of the quarter glass using the printed dots (F) on the quarter glass as a guide. Do not apply the body primer to the quarter glass, and do not mix up the body and glass primer applicators. Never touch the primed surfaces with your hands. If you do, the adhesive may not bond to the quarter glass properly, causing a leak after the quarter glass is installed. Keep water, dust, and abrasive materials away from the primed surfaces. 3. Apply a light coat of the body primer to any exposed paint or metal on the quarter glass mounting flange. Let the body primer dry for at least 10 minutes. NOTE: Do not apply the glass primer to the body. Do not apply the body primer to any remaining original adhesive on the flange. Be careful not to mix up the body and glass primer sponges. Never touch the primed surfaces with your hands. cardiagn.com 1. Install the quarter glass front seal (A) with the adhesive tape to the molding (B). 5. Put the cartridge in a caulking gun, and run a continuous bead of adhesive (A) on the quarter glass (B) along the edge of the front seal (C) and the molding (D) as shown. NOTE: Apply the adhesive within 30 minutes after applying the glass primer. Apply the adhesive to the front area (E) and the corner areas (F) using the printed dots (G) on the quarter glass as a guide. Make a slightly thicker bead at each corner. cardiagn.com 4. Cut a ‘‘V’’ in the end of the nozzle (A) on the adhesive cartridge as shown. 6. Hold the quarter glass (A) with the suction cups (B) over the opening, align the clips (C), and set it down on the adhesive. Lightly push on the quarter glass until its edges are fully seated on the adhesive all the way around. NOTE: Do not open or close any of the doors for about an hour until the adhesive is dry. 7. Remove the excess adhesive with a putty knife or a shop towel dampened with isopropyl alcohol. 8. Wait at least an hour for the adhesive to dry, then spray water over the quarter glass and check for leaks. Mark the leaking areas, and let the quarter glass dry, then seal with sealant. Let the vehicle stand for at least 4 hours after quarter glass installation. If the vehicle has to be used within the first 4 hours, it must be driven slowly. Slam the doors with all the windows rolled up. Twist the body excessively (such as when going in and out of driveways at an angle or driving over rough, uneven roads). 2. Quarter Pillar Trim - Install 3. B-Pillar Upper Trim - Install cardiagn.com 9. Advise the customer not to do the following things for 2 to 3 days: Quarter Glass Removal and Installation 1. C-Pillar Lower Trim - Remove 2. Quarter Glass - Remove 2. With a helper on the outside, pull the piano wire (A) back and forth in a sawing motion. Hold the piano wire as close to the quarter glass (B) as possible to prevent damage to the body, and carefully cut through the adhesive (C) around the entire quarter glass. 3. Carefully remove the quarter glass. 4. Scrape smooth the original adhesive with a knife until there is a thickness of about 1 mm (0.04 in) - 2 mm (0.08 in) on the bonding surface around the entire quarter glass opening flange. NOTE: Do not scrape down to the painted surface of the body; damaged paint will interfere with proper bonding. Remove the clips from the body. Cutting positions cardiagn.com 1. Apply the protective tape along the inside and outside edges of the body. Make a hole with an awl through the adhesive from inside the vehicle. Push a piece of piano wire through the hole, and wrap each end around a piece of wood. cardiagn.com 1. Quarter Glass - Install 1. Apply a light coat of the primer to the quarter glass (A) along the edge of the front seal (B) and the molding (C) as shown, then lightly wipe it off with gauze or cheesecloth. NOTE: Apply the primer to the corner areas (D) of the quarter glass using the printed dots (E) on the quarter glass as a guide. Do not apply the body primer to the quarter glass, and do not mix up the body and glass primer applicators. Never touch the primed surfaces with your hands. If you do, the adhesive may not bond to the quarter glass properly, causing a leak after the quarter glass is installed. Keep water, dust, and abrasive materials away from the primed surfaces. NOTE: Do not apply the glass primer to the body. Do not apply the body primer to any remaining original adhesive on the flange. Be careful not to mix up the body and glass primer sponges. Never touch the primed surfaces with your hands. 3. Cut a ‘‘V’’ in the end of the nozzle (A) on the adhesive cartridge as shown. cardiagn.com 2. Apply a light coat of the body primer to any exposed paint or metal on the quarter glass mounting flange. Let the body primer dry for at least 10 minutes. 4. Put the cartridge in a caulking gun, and run a continuous bead of adhesive (A) on the quarter glass (B) along the edge of the front seal (C) and the molding (D) as shown. NOTE: Apply the adhesive within 30 minutes after applying the glass primer. Apply the adhesive to the corner areas (E) using the printed dots (F) on the quarter glass as a guide. 5. Hold the quarter glass (A) with the suction cups (B) over the opening, align the clips (C), and set it down on the adhesive. Lightly push on the quarter glass until its edges are fully seated on the adhesive all the way around. NOTE: Do not open or close any of the doors for about an hour until the adhesive is dry. 6. Remove the excess adhesive with a putty knife or a shop towel dampened with isopropyl alcohol. 7. Wait at least an hour for the adhesive to dry, then spray water over the quarter glass and check for leaks. Mark the leaking areas, and let the quarter glass dry, then seal with sealant. Let the vehicle stand for at least 4 hours after quarter glass installation. If the vehicle has to be used within the first 4 hours, it must be driven slowly. 8. Advise the customer not to do the following things for 2 to 3 days: Slam the doors with all the windows rolled up. Twist the body excessively (such as when going in and out of driveways at an angle or driving over rough, uneven roads). 2. C-Pillar Lower Trim - Install cardiagn.com Make a slightly thicker bead at each corner. cardiagn.com Rear Door Glass and Regulator Removal and Installation NOTE: How to read the torque specifications. 1. Rear Door Plastic Cover - Remove 2. Rear Door Glass - Remove 1. Remove the nut (A) and the bolts (B, C). NOTE: 4-door does not need to remove the rear door rear lower sash. cardiagn.com 2. 5-door: Remove the rear door rear lower sash (D). 3. Lower the rear door glass (A) until you can see the bolts (B), then remove them. 3. Rear Door Regulator - Remove 1. Disconnect the connector (A). 2. Remove the rear door regulator (B). cardiagn.com 4. Carefully remove the rear door glass out through the window slot. cardiagn.com 4. All Removed Parts - Install 1. Install the parts in the reverse order of removal. 5. Door Glass - Adjust cardiagn.com NOTE: Apply multipurpose grease to all sliding surfaces of the rear door regulator (A) where shown. Rear Door Glass Inner Weatherstrip Removal and Installation 1. Rear Door Panel - Remove cardiagn.com 2. Rear Door Glass Inner Weatherstrip - Remove 3. All Removed Parts - Install 1. Install the parts in the reverse order of removal. Rear Door Glass Outer Weatherstrip Removal and Installation 1. Rear Door Plastic Cover - Remove 2. Rear Door Glass Outer Weatherstrip - Remove 1. Release the hooks (A) with a flat-tip screwdriver from inside of the door. cardiagn.com 2. Remove the rear door glass outer weatherstrip (B). 3. All Removed Parts - Install 1. Install the parts in the reverse order of removal. cardiagn.com Rear Window Defogger Circuit Diagram cardiagn.com Rear Window Defogger Circuit Diagram cardiagn.com Rear Window Defogger Circuit Diagram cardiagn.com Rear Window Defogger Circuit Diagram Rear Window Defogger Component Location Index cardiagn.com 2-door 4-door cardiagn.com cardiagn.com cardiagn.com Rear Window Defogger Component Location Index cardiagn.com Rear Window Defogger System Description - Control/Function The Timer Function cardiagn.com The rear window defogger provides the timer control function that is controlled by the climate control unit. The timer control is operated by turning the vehicle to the ON mode, then turning on the rear window defogger/mirror defogger switch*. The timer operating time varies according to ambient temperature. If the rear window defogger/mirror defogger* switch is turned on when the timer is active, it toggles between ON and OFF every time the switch is pressed. *: With Mirror Defogger Rear Window Defogger System Description - System Diagram cardiagn.com For locations of each component on the vehicle, refer to the Component Location Index Rear Window Defogger Wire Repair 1. Defogger Wire - Repair NOTE: To make an effective repair, the broken section must be no longer than 25 mm (1.0 in). 1. Lightly rub the area around the broken section (A) with fine steel wool, then clean it with isopropyl alcohol. 3. Using a small brush, apply a heavy coat of silver conductive paint (commercially available) (A) extending about 3.0 mm (0.1 in) on both sides of the break. Allow 25 minutes to dry. 4. Do the function test to confirm that the wire is repaired. 5. Apply a second coat of paint in the same way. Let it dry 3 hours before removing the tape. cardiagn.com 2. Carefully mask above and below the broken area of the rear window defogger wire (B) with cellophane tapes (C). Rear Window Removal and Installation 1. Rear Shelf - Remove 2. High Mount Brake Light Cover - Remove 3. Rear Window - Remove 2. Pull down the rear area of the headliner (A). NOTE: Take care not to bend the headliner excessively, or you may crease or break it. cardiagn.com 1. Disconnect the terminals (A). 3. If the original rear window will be reinstalled, make the alignment marks across the rear window and the body with a grease pencil. 4. Apply the protective tape along the inside and outside edges of the body. Make a hole with an awl through the adhesive from inside the vehicle at a corner of the rear window. Push a piece of piano wire through the hole, and wrap each end around a piece of wood. 5. Open the trunk lid. 7. With an assistant on the outside, pull the piano wire (A) back and forth in a sawing motion. Hold the piano wire as close to the rear window (B) as possible to prevent damage to the body, and carefully cut through the adhesive (C) around the entire rear window. 8. Carefully remove the rear window. 9. Scrape smooth the original adhesive with a knife, until there is a thickness of about 1 mm (0.04 in) - 2mm (0.08 in) on the bonding surface around the entire rear window opening flange. NOTE: Do not scrape down to the painted surface of the body; damaged paint will interfere with proper bonding. Remove the clips and the fasteners from the body. 10. Clean the body bonding surface with a shop towel dampened with isopropyl alcohol. After cleaning, keep oil, grease, and water from getting on the surface. 11. If you are reinstalling the original rear window, scrape off the original adhesive, the clips, the fasteners, and the rubber dams from the rear window with a putty knife. Clean the bonding surfaces on the inside face and the edge of the rear window with isopropyl alcohol. Make sure the bonding surface is kept free of water, oil, and grease. cardiagn.com 6. Remove the rubber dam (A) from the lower edge of the rear window (B). If necessary, cut the rubber dam with a utility knife. 1. Rear Window - Install 1. Install the rubber dams (A, B, C) with the adhesive tape to the inside face of the rear window (D) as shown. NOTE: Be careful not to touch the rear window where the adhesive will be applied. Make sure the rubber dams line up with the alignment marks (E). Rubber dams Length (A) 1,075 mm (42.32 in) (B) 13 mm (0.51 in) (C) 753 mm (29.65 in) cardiagn.com Cutting Positions cardiagn.com 2. Install the rubber dam (A) with the adhesive tape to the inside face of the rear window (B) as shown. NOTE: Be careful not to touch the rear window where the adhesive will be applied. 3. If you are installing the new rear window (A), set the rear window in the opening, and center it. Make the alignment marks (B) across the rear window and the body with a grease pencil at the four points shown. NOTE: Be careful not to touch the rear window where the adhesive will be applied. 4. Remove the rear window. cardiagn.com Make sure the rubber dam lines up with the alignment marks (C). 5. Apply a light coat of primer to the rear window (A) along the rubber dams (B, C) as shown, then lightly wipe it off with gauze or cheesecloth. NOTE: Apply the primer to the corner areas (D) of the rear window using the printed dots (E) on the rear window as a guide. Do not apply the body primer to the rear window, and be careful not to mix up the body and glass primer applicators. Never touch the primed surfaces with your hands. If you do, the adhesive may not bond to the rear window properly, causing a leak after the rear window is installed. Keep water, dust, and abrasive materials away from the primed surfaces. NOTE: Do not apply the glass primer to the body. Do not apply the body primer to any remaining original adhesive on the flange. Be careful not to mix up the body and glass primer applicators. Never touch the primed surfaces with your hands. 7. Cut a ‘‘V’’ at the end of the adhesive cartridge nozzle (A) as shown. cardiagn.com 6. Apply a light coat of the body primer to any exposed paint or metal on the rear window mounting flange. Let the body primer dry for at least 10 minutes. 8. Put the cartridge in a caulking gun, and run a continuous bead of the adhesive (A) to the rear window (B) along the rubber dams (C, D) as shown. NOTE: Apply the adhesive within 30 minutes after applying the glass primer. Apply the adhesive to the corner areas (E) of the rear window using the printed dots (F) on the rear window as a guide. Make a slightly thicker bead at each corner. 9. Hold the rear window with the suction cups over the opening, align it with the alignment marks you made in step 4, and set it down on the adhesive. Lightly push on the rear window until its edges are fully seated on the adhesive all the way around. Carefully remove the suction cups. 10. Remove the excess adhesive with a putty knife or a shop towel dampened with isopropyl alcohol. 11. Wait at least an hour for the adhesive to dry, then spray water over the rear window and check for leaks. Mark the leaking areas, let the rear window dry, then seal with sealant. Let the vehicle stand for at least 4 hours after rear window installation. If the vehicle has to be used within the first 4 hours, it must be driven slowly. 12. Advise the customer not to do the following things for 2 to 3 days: Do not slam the doors with all the windows rolled up. Do not twist the body excessively (such as when going in and out of driveways at an angle or driving over rough, uneven roads). cardiagn.com NOTE: Do not open or close any of the doors for about an hour until the adhesive is dry. 13. Install the rear area of the headliner (A). cardiagn.com 14. Connect the terminals (A). 2. High Mount Brake Light Cover - Install 3. Rear Shelf - Install Rear Window Removal and Installation 4-door 1. Rear Shelf - Remove 2. Rear Window - Remove 2. Pull down the rear area of the headliner (A). NOTE: Take care not to bend the headliner excessively, or you may crease or break it. cardiagn.com 1. Disconnect the terminals (A). 3. If the original rear window will be reinstalled, make the alignment marks across the rear window and the body with a grease pencil. 4. Apply the protective tape along the inside and outside edges of the body. Make a hole with an awl through the adhesive from inside the vehicle at a corner of the rear window. Push a piece of piano wire through the hole, and wrap each end around a piece of wood. 5. Open the trunk lid. 7. With an assistant on the outside, pull the piano wire (A) back and forth in a sawing motion. Hold the piano wire as close to the rear window (B) as possible to prevent damage to the body, and carefully cut through the adhesive (C) around the entire rear window. 8. Carefully remove the rear window. 9. Scrape smooth the original adhesive with a knife, until there is a thickness of about 1 mm (0.04 in) - 2 mm (0.08 in) on the bonding surface around the entire rear window opening flange. NOTE: Do not scrape down to the painted surface of the body; damaged paint will interfere with proper bonding. Remove the clips and the fasteners from the body. 10. Clean the body bonding surface with a shop towel dampened with isopropyl alcohol. After cleaning, keep oil, grease, and water from getting on the surface. 11. If you are reinstalling the original rear window, scrape off the original adhesive, the clips, the fasteners, and the rubber dams from the rear window with a putty knife. Clean the bonding surfaces on the inside face and the edge of the rear window with isopropyl alcohol. Make sure the bonding surface is kept free of water, oil, and grease. cardiagn.com 6. Remove the rubber dam (A) from the lower edge of the rear window (B). If necessary, cut the rubber dam with a utility knife. cardiagn.com Cutting Positions 5-door 1. Tailgate Lower Trim Panel - Remove 2. Tailgate Upper Spoiler - Remove 3. Tailgate Middle Spoiler - Remove 4. Rear Window - Remove 1. Disconnect the terminals (A). 2. If the original rear window will be reinstalled, make the alignment marks across the rear window and the body with a grease pencil. 3. Apply the protective tape along the inside and outside edges of the body. Make a hole with an awl through the adhesive from inside the vehicle at a corner of the rear window. Push a piece of piano wire through the hole, and wrap each end around a piece of wood. 4. Open the tailgate. Cutting Positions 6. Carefully remove the rear window. 7. Scrape smooth the original adhesive with a knife, until there is a thickness of about 1 mm (0.04 in) - 2 mm (0.08 in) on the bonding surface around the entire rear window opening flange. NOTE: Do not scrape down to the painted surface of the body; damaged paint will interfere with proper bonding. Remove the clips and the fasteners from the body. 8. Clean the body bonding surface with a shop towel dampened with isopropyl alcohol. After cleaning, keep oil, grease, and water from getting on the surface. 9. If you are reinstalling the original rear window, scrape off the original adhesive, the clips, the fasteners, and the rubber dams from the rear window with a putty knife. Clean the bonding surfaces on the inside face and the edge of the rear window with isopropyl alcohol. Make sure the bonding surface is kept free of water, oil, and grease. 4-door 1. Rear Window - Install cardiagn.com 5. With an assistant on the outside, pull the piano wire (A) back and forth in a sawing motion. Hold the piano wire as close to the rear window (B) as possible to prevent damage to the body, and carefully cut through the adhesive (C) around the entire rear window. 1. Install the clips (A) and the fasteners (B) with the adhesive tape to the inside face of the rear window (C) as shown. NOTE: Be careful not to touch the rear window where the adhesive will be applied. Before installing the clips, apply the glass primer to the area where the adhesive tape will be applied. Make sure the index tabs (D) on the clips face the right side. 2. Install the rubber dams (A, B, C) with the adhesive tape to the inside face of the rear window (D) as shown. NOTE: Be careful not to touch the rear window where the adhesive will be applied. Make sure the rubber dams line up with the alignment marks (E). Rubber dams Length (A) 1,075 mm (42.32 in) (B) 18 mm (0.71 in) (C) 749 mm (29.49 in) cardiagn.com Make sure the clips and the fasteners line up with the alignment marks (E). NOTE: Be careful not to touch the rear window where the adhesive will be applied. Make sure the rubber dam line up with the alignment marks (C). cardiagn.com 3. Install the rubber dam (A) with the adhesive tape to the inside face of the rear window (B) as shown. 5. If you are installing the new rear window (A), set the rear window in the opening, and center it. Make the alignment marks (B) across the rear window and the body with a grease pencil at the four points shown. NOTE: Be careful not to touch the rear window where the adhesive will be applied. Make sure the clips (C) contact with the edge of the body holes. 6. Remove the rear window. cardiagn.com 4. Install the fasteners (A) with the adhesive tape to the rear window opening flange of the body as shown. 7. Apply a light coat of primer to the rear window (A) along the rubber dams (B, C) as shown, then lightly wipe it off with gauze or cheesecloth. NOTE: Apply the primer to the corner areas (D) of the rear window using the printed dots (E) on the rear window as a guide. Do not apply the body primer to the rear window, and be careful not to mix up the body and glass primer applicators. Never touch the primed surfaces with your hands. If you do, the adhesive may not bond to the rear window properly, causing a leak after the rear window is installed. Keep water, dust, and abrasive materials away from the primed surfaces. NOTE: Do not apply the glass primer to the body. Do not apply the body primer to any remaining original adhesive on the flange. Be careful not to mix up the body and glass primer applicators. Never touch the primed surfaces with your hands. 9. Cut a ‘‘V’’ at the end of the adhesive cartridge nozzle (A) as shown. cardiagn.com 8. Apply a light coat of the body primer to any exposed paint or metal on the rear window mounting flange. Let the body primer dry for at least 10 minutes. 10. Put the cartridge in a caulking gun, and run a continuous bead of the adhesive (A) to the rear window (B) along the rubber dams (C, D) as shown. NOTE: Apply the adhesive within 30 minutes after applying the glass primer. Apply the adhesive to the corner areas (E) of the rear window using the printed dots (F) on the rear window as a guide. Make a slightly thicker bead at each corner. 11. Hold the rear window with the suction cups over the opening, align it with the alignment marks you made in step 5, and set it down on the adhesive. Lightly push on the rear window until its edges are fully seated on the adhesive all the way around. Carefully remove the suction cups. 12. Remove the excess adhesive with a putty knife or a shop towel dampened with isopropyl alcohol. 13. Wait at least an hour for the adhesive to dry, then spray water over the rear window and check for leaks. Mark the leaking areas, let the rear window dry, then seal with sealant. Let the vehicle stand for at least 4 hours after rear window installation. If the vehicle has to be used within the first 4 hours, it must be driven slowly. 14. Advise the customer not to do the following things for 2 to 3 days: Do not slam the doors with all the windows rolled up. Do not twist the body excessively (such as when going in and out of driveways at an angle or driving over rough, uneven roads). cardiagn.com NOTE: Do not open or close any of the doors for about an hour until the adhesive is dry. 15. Install the rear area of the headliner (A). cardiagn.com 16. Connect the terminals (A). 2. Rear Shelf - Install 5-door 1. Rear Window - Install 1. Install the fasteners (A) with the adhesive tape to the inside face of the rear window (B) as shown. NOTE: Be careful not to touch the rear window where the adhesive will be applied. Before installing the fasteners the glass primer to the area where the adhesive tape will be applied. cardiagn.com Make sure the fasteners line up with the alignment marks (C). 2. Install the rubber dams (A) with the adhesive tape to the inside face of the rear window (B) as shown. NOTE: Be careful not to touch the rear window where the adhesive will be applied. Make sure the rubber dams line up with the alignment marks (C). Rubber dams (A): Length 40 mm (1.57 in) 4. Install the rubber dams (A, B, C) with the adhesive tape to the inside face of the rear window (D) as shown. NOTE: Be careful not to touch the rear window where the adhesive will be applied. Make sure the rubber dams line up with the alignment marks (E). Rubber dams Length (A) 1,000 mm (39.37 in) (B) 605 mm (23.82 in) (C) 975 mm (38.39 in) cardiagn.com 3. Install the seal (D) line up with the alignment marks (E). cardiagn.com 6. If you are installing the new rear window (A), set the rear window in the opening, and center it. Make the alignment marks (B) across the rear window and the tailgate with a grease pencil at the four points shown. NOTE: Be careful not to touch the rear window where the adhesive will be applied. 7. Remove the rear window. cardiagn.com 5. Install the fasteners (A) with the adhesive tape to the rear window opening flange of the tailgate as shown. 8. Apply a light coat of primer to the rear window (A) along the rubber dams (B) as shown, then lightly wipe it off with gauze or cheesecloth. NOTE: Apply the primer to the corner areas (C) of the rear window using the printed dots (D) on the rear window as a guide. Do not apply the body primer to the rear window, and be careful not to mix up the body and glass primer applicators. Never touch the primed surfaces with your hands. If you do, the adhesive may not bond to the rear window properly, causing a leak after the rear window is installed. Keep water, dust, and abrasive materials away from the primed surfaces. NOTE: Do not apply the glass primer to the body. Do not apply the body primer to any remaining original adhesive on the flange. Be careful not to mix up the body and glass primer applicators. Never touch the primed surfaces with your hands. 10. Cut a ‘‘V’’ at the end of the adhesive cartridge nozzle (A) as shown. cardiagn.com 9. Apply a light coat of the body primer to any exposed paint or metal on the rear window mounting flange. Let the body primer dry for at least 10 minutes. 11. Put the cartridge in a caulking gun, and run a continuous bead of the adhesive (A) to the rear window (B) along the rubber dams (C) as shown. NOTE: Apply the adhesive within 30 minutes after applying the glass primer. Apply the adhesive to the corner areas (D) of the rear window using the printed dots (E) on the rear window as a guide. Make a slightly thicker bead at each corner. 12. Hold the rear window with the suction cups over the opening, align it with the alignment marks you made in step 6, and set it down on the adhesive. Lightly push on the rear window until its edges are fully seated on the adhesive all the way around. Carefully remove the suction cups. 13. Remove the excess adhesive with a putty knife or a shop towel dampened with isopropyl alcohol. 14. Wait at least an hour for the adhesive to dry, then spray water over the rear window and check for leaks. Mark the leaking areas, let the rear window dry, then seal with sealant. Let the vehicle stand for at least 4 hours after rear window installation. If the vehicle has to be used within the first 4 hours, it must be driven slowly. 15. Advise the customer not to do the following things for 2 to 3 days: Do not slam the doors with all the windows rolled up. Do not twist the body excessively (such as when going in and out of driveways at an angle or driving over rough, uneven roads). cardiagn.com NOTE: Do not open or close any of the doors for about an hour until the adhesive is dry. 16. Connect the terminals (A). 3. Tailgate Upper Spoiler - Install 4. Tailgate Lower Trim Panel - Install cardiagn.com 2. Tailgate Middle Spoiler - Install Rearview Mirror Removal and Installation Without Multipurpose Camera Unit 1. Rearview Mirror - Remove 2. With automatic dimming mirror: Disconnect the connector (A). cardiagn.com 1. With automatic dimming mirror: Remove the rearview mirror harness cover (A). 3. Loosen the screw (A). 2. All Removed Parts - Install 1. Install the parts in the reverse order of removal. With Multipurpose Camera Unit 1. Multipurpose Camera Cover - Remove (With Multipurpose Camera Unit) 2. Rearview Mirror - Remove 1. With automatic dimming mirror: Disconnect the connector (A). cardiagn.com 4. Slide the rearview mirror (B) rearward and off the mount (C). 2. Loosen the screw (A). 3. All Removed Parts - Install 1. Install the parts in the reverse order of removal. cardiagn.com 3. Slide the rearview mirror (B) rearward and off the mount (C).