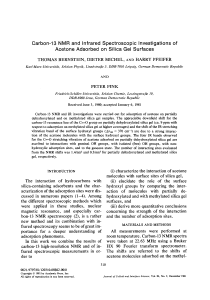

Desalination 250 (2010) 982–984 Contents lists available at ScienceDirect Desalination j o u r n a l h o m e p a g e : w w w. e l s ev i e r. c o m / l o c a t e / d e s a l Investigations of silica scaling on reverse osmosis membranes☆ Gerd Braun a,⁎, Wolfgang Hater b, Christian zum Kolk b, Claire Dupoiron b, Timo Harrer a, Thomas Götz a a b Cologne University of Applied Sciences, Köln, Germany BKG Water Solutions, Düsseldorf, Germany a r t i c l e i n f o Available online 21 October 2009 Keywords: Membrane scaling Silica scaling Reverse osmosis Antiscalants a b s t r a c t In reverse osmosis systems with high silica water severe and irreversible membrane scaling can be observed. But suitable test methods to find an appropriate antiscalant agent and the optimal dosage are missing. Usually only the silicate concentration in the feed water is regarded. In this paper the results of laboratory experiments about the influence of Ca2+- and Mg2+-ions on the behaviour of supersaturated solutions of silica in different test waters are discussed first. After that the new developed membrane-based test method to determine the effectiveness of antiscalants is presented. The applied different methods of analysis enabled the differentiation of three groups of silicates: ‘monomeric’, ‘polymeric’ and ‘filterable’. With the test method the strong impact of silicate scaling was proven, even if only small amounts of scale had been formed. It could be shown, that the ‘polymeric silica’ is mainly responsible for the membrane scaling. The kinetic of the formation of ‘polymeric silica’ is strongly influenced by the cations and the pH-value. It could be demonstrated that the use of a suitable antiscalant makes it possible to operate the plant at significantly higher recovery rates. © 2009 Elsevier B.V. All rights reserved. 1. Introduction In many reverse osmosis systems with high silica containing water, there is the problem of severe and irreversible membrane scaling. The engineering task is to find out the appropriate antiscalant agent and the optimal dosage. However, suitable test methods are missing. Usually only the silicate concentration in the feed water is regarded. As the contents of the other ions, i.e. above all calcium and magnesium are not considered, this method is incorrect and can lead to substantial problems. In this paper the results of laboratory experiments about the influence of ions on the behaviour of supersaturated solutions of silica in different test waters are discussed first. After that the new membrane-based test method developed to determine the effectiveness of antiscalants is presented. Subsequently, the results of the test series about the influence of Ca2+ and Mg2+ and about the addition of antiscalants on silica membrane scaling are discussed. 2. Different forms of silicates in water The silicates present in natural waters exist in different forms. When the concentration of silica increases, the soluble silica tends to polymerise [2]. The silicate ions polymerisation leads to the formation of “silica scale”, which is a complex and amorphous product, a complicated mixture of ☆ Presented at the 12th Aachener Membrane Kolloquium, Aachen, Germany, 29-30 October, 2008. ⁎ Corresponding author. Tel.: +49 221 8275 2203. E-mail address: gerd.braun@fh-koeln.de (G. Braun). 0011-9164/$ – see front matter © 2009 Elsevier B.V. All rights reserved. doi:10.1016/j.desal.2009.09.086 numerous components, and it is impossible to know precisely which species are present and how they will react. To determine the chemical structure of the silicates in the water, the samples in this paper have been analysed according to two different methods: • Small size units (‘monomeric silicates’). SPM (Spectro-Photometric Method), Hach method 8185 • Total amount of silicates AAS (Atomic Absorption Spectrometry) / ICP (Inductively Coupled Plasma) The amount of precipitate resp. gel (‘filterable’ silicate) is determined from the difference between the silicate concentration in filtered water samples at the very beginning of the test and the concentration of ‘polymeric silicates’. 3. Laboratory experiments on the influence of cations According to Neofotistou et al. [3], Demadis et al. [4] and Koo et al. [5], the presence of calcium or magnesium ions favours the formation of silicates deposits. According to Iler [1] at pH 7 the silica particles are negatively charged and repel each other. But if salt is added, the charge repulsion is reduced and aggregation and gel formation occur. Figs. 1 and 2 show the influence of the Ca2+-concentration on the measured silica concentration vs. time. In these experiments different amounts of NaCl and CaCl2 are added to the initial solution of 1000 ppm SiO2. The results of the AAS show that the more calcium the solution contains, the higher is the final amount of ‘filterable’ and ‘polymeric’ G. Braun et al. / Desalination 250 (2010) 982–984 983 Until the test water is concentrated up to the desired concentration level, the concentrate is recycled to the feed tank. As soon as the desired volumetric concentration ratio is reached, the test plant is operated continuously at that concentration level, and with a constant permeate flux due to pressure adjustment. The total permeate amount produced up to a pressure of 60 bars serves as a criterion for the scaling potential of the test water. In cases where the membrane is not fully blocked the slope of the pressure increase at constant flux is used to determine the scaling potential of the water. Besides the operating parameters of the plant, the ionic composition was analysed once per hour by means of ICP. 5. Results from the test runs Fig. 1. SiO2-concentration vs. time NaCl/CaCl2 AAS. The blocked membrane was examined under the SEM, and the element distribution of the scaling layer was determined by EDX. Fig. 4 shows the distribution of Ca and Si in a scaling layer. One clearly recognizes that these elements form the scaling layer in separate structures. In case of no Ca2+ in the test water, but with high concentrations of silicate, scaling occurs in an amorphous layer. Fig. 5 shows very clearly the different impact of Ca2+ and Mg2+ ions on the rate of scaling for different silica concentrations and Fig. 6 shows the big influence of the added antiscalant. Fig. 2. SiO2-concentration vs. time NaCl/CaCl2 SPM. silicates, and the quicker this final concentration will be reached. In the case of the SPM values it was found that there is almost no influence of the CaCl2 concentration on the final monomeric silica concentration. 4. Development of the test method To investigate the observed effects at a reverse osmosis plant, a new test method was developed. The test set-up is shown in Fig. 3. Fig. 3. Membrane test set-up. Fig. 4. Distribution of Ca and Si. Fig. 5. Produced permeate amount vs. SiO2 brine-concentration. 984 G. Braun et al. / Desalination 250 (2010) 982–984 Fig. 9. Pressure increase vs. antiscalant and pH left side at 150 ppm SiO2, right side at 275 ppm SiO2. Fig. 6. Produced permeate amount vs. SiO2 brine-concentration (6.9 mmol/L Ca2+/ 1.5 mmol/L Mg2+). Sheikholeslami et al. [6] reported about the dependence of the polymerisation time from the pH-value at SiO2-concentrations at 360 to 400 ppm. Between pH 6.5 and 8.5 the polymerisation is relatively fast but it decreases to very low values at pH 5.5. Figs. 7 and 8 show the results for test runs at a pH-value of 5.5 at SiO2-concentrations of 150 ppm and 275 ppm with and without antiscalant Osmotech 1309. Osmotech 1309 is an antiscalant and antifoulant used for the prevention of inorganic scale deposits in membrane systems. This antiscalant is a liquid product based on phosphonic acids, phosphonocarboxylic acids and special polycarboxylic acids. It is an efficient scale inhibitor against various minerals and designed especially against silica fouling. Up to SiO2-concentrations of 150 ppm the pressure increase at constant flux could be kept relatively low by using Osmotech 1309. At significantly higher SiO2-concentrations of 275 ppm the used antiscalant is able to decrease the pressure increase per produced volume of permeate in the ratio of 1.7 (0.36 bar/L/0.21 bar/L). In Fig. 9 the influence of the used antiscalant is shown for test runs at different pH-values and SiO2-concentrations. The pressure increase rises with increasing pH and increasing SiO2-concentration. But by adding a suitable antiscalant the pressure increase could be decreased in comparison to the respective test run without antiscalant. 6. Conclusions Fig. 7. With Osmotech 1309, pH 5.5. The different methods of analysis made it possible to distinguish three groups of silicates: ‘monomeric’, ‘polymeric’ and ‘filterable’. Ca2+ and Mg2+-ions have a strong influence on the formation of filterable silicate and on the kinetics of the formation of the different silicate species. With this new test method the strong impact of silicate scaling was proven, even if only small amounts of scale had been formed. It could be shown, that the ‘polymeric silica’ is mainly responsible for the membrane scaling. The kinetic of the formation of ‘polymeric silica’ is strongly influenced by the cations and the pH-value. It could be demonstrated that the use of a suitable antiscalant makes it possible to operate the plant at significantly higher recovery rates. References [1] R.K. Iler, The Chemistry of Silica: Solubility, Polymerization, Colloid and Surface Properties, and Biochemistry, 1979 866 p. [2] J.S. Gill, Inhibition of silica-silicate deposit in industrial waters, Colloids and surfaces A : Physicochemical and Engineering Aspects 74 (1993) 101–106. [3] E. Neofotistou, K.D. Demadis, Use of antiscalants for mitigation of silica (SiO2) fouling and deposition: fundamentals and applications in desalination systems, Desalination 167 (2004) 257–272. [4] K.D. Demadis, E. Neofotistou, E. Mavredaki, M. Tsiknakis, E.-M. Sarigiannidou, Solving water treatment's “Gordian Knots” the “Green Way”, Eurocorr (2005). [5] T. Koo, Y.J. Lee, R. Sheikholeslami, Silica fouling and cleaning of reverse osmosis membranes, Desalination 139 (2001) 43–56. [6] Roya Sheikholeslami, I.S. Al-Mutaz, T. Koo, A. Young, Pretreatment and the effect of cations and anions on prevention of silica fouling, Desalination 139 (2001) S.83–S.95. Fig. 8. SiO2 275 mg/L, pH 5.5.