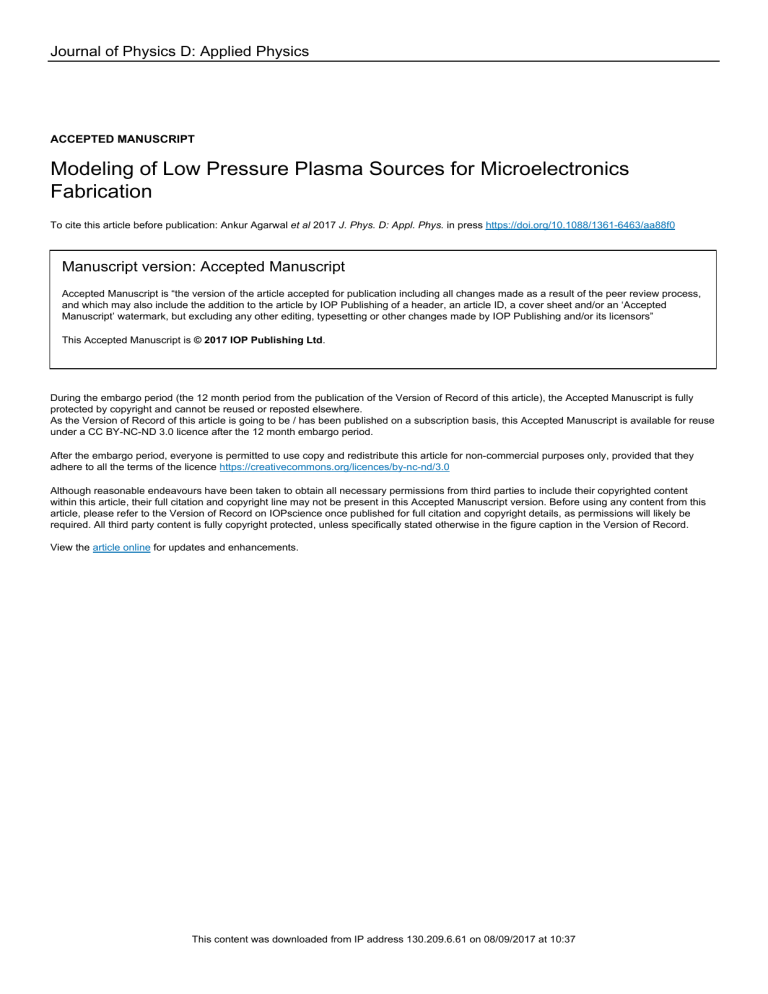

Journal of Physics D: Applied Physics ACCEPTED MANUSCRIPT Modeling of Low Pressure Plasma Sources for Microelectronics Fabrication To cite this article before publication: Ankur Agarwal et al 2017 J. Phys. D: Appl. Phys. in press https://doi.org/10.1088/1361-6463/aa88f0 Manuscript version: Accepted Manuscript Accepted Manuscript is “the version of the article accepted for publication including all changes made as a result of the peer review process, and which may also include the addition to the article by IOP Publishing of a header, an article ID, a cover sheet and/or an ‘Accepted Manuscript’ watermark, but excluding any other editing, typesetting or other changes made by IOP Publishing and/or its licensors” This Accepted Manuscript is © 2017 IOP Publishing Ltd. During the embargo period (the 12 month period from the publication of the Version of Record of this article), the Accepted Manuscript is fully protected by copyright and cannot be reused or reposted elsewhere. As the Version of Record of this article is going to be / has been published on a subscription basis, this Accepted Manuscript is available for reuse under a CC BY-NC-ND 3.0 licence after the 12 month embargo period. After the embargo period, everyone is permitted to use copy and redistribute this article for non-commercial purposes only, provided that they adhere to all the terms of the licence https://creativecommons.org/licences/by-nc-nd/3.0 Although reasonable endeavours have been taken to obtain all necessary permissions from third parties to include their copyrighted content within this article, their full citation and copyright line may not be present in this Accepted Manuscript version. Before using any content from this article, please refer to the Version of Record on IOPscience once published for full citation and copyright details, as permissions will likely be required. All third party content is fully copyright protected, unless specifically stated otherwise in the figure caption in the Version of Record. View the article online for updates and enhancements. This content was downloaded from IP address 130.209.6.61 on 08/09/2017 at 10:37 Page 1 of 44 pt Modeling of Low Pressure Plasma Sources for Microelectronics Fabrication us cri Ankur Agarwal,1,a Kallol Bera,1 Jason Kenney,1 Alexandre Likhanskii,2 and Shahid Rauf1,b Applied Materials, Inc. 1 1140 E. Arques Ave., Sunnyvale, CA 94085 2 35 Dory Road, Gloucester, MA 01930 a Now with KLA - Tencor Author to whom correspondence should be addressed. Email: Shahid_Rauf@amat.com an b Abstract dM Chemically reactive plasmas operating in the 1 mTorr – 10 Torr pressure range are widely used for thin film processing in the semiconductor industry. Plasma modeling has come to play an important role in the design of these plasma processing systems. A number of 3-dimensional (3D) fluid and hybrid plasma modeling examples are used to illustrate the role of computational investigations in design of plasma processing hardware for applications such as ion implantation, pte deposition, and etching. A model for a rectangular inductively coupled plasma (ICP) source is described, which is employed as an ion source for ion implantation. It is shown that gas pressure strongly influences ion flux uniformity, which is determined by the balance between the location ce of plasma production and diffusion. The effect of chamber dimensions on plasma uniformity in a rectangular capacitively coupled plasma (CCP) is examined using an electromagnetic plasma model. Due to high pressure and small gap in this system, plasma uniformity is found to be primarily determined by the electric field profile in the sheath / pre-sheath region. A 3D model Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 is utilized to investigate the confinement properties of a mesh in a cylindrical CCP. Results 1 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 pt highlight the role of hole topology and size on the formation of localized hot-spots. A 3D electromagnetic plasma model for a cylindrical ICP is used to study inductive vs. capacitive us cri power coupling and how placement of ground return wires influences it. Finally, a 3D hybrid plasma model for an electron beam generated magnetized plasma is used to understand the role ce pte dM an of reactor geometry on plasma uniformity in the presence of E×B drift. Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 Page 2 of 44 2 Page 3 of 44 pt 1. Introduction Low and moderate pressure (1 mTorr – 10 Torr) chemically-reactive plasmas are widely used us cri for thin film processing (etching, deposition, implantation, film modification, etc.) during microelectronics fabrication. [1] These plasmas provide a unique combination of chemically reactive radicals and energetic ions, which has proven essential for continued miniaturization of microelectronics circuits. With leading edge semiconductor devices approaching critical dimensions of 5 nm and many films now thinner than 2 nm, it is paramount to control all plasma an properties that can impact device characteristics: ion energy and angular distribution, ion-toneutral flux ratio, substrate temperature, etc. This need for enhanced control has led to rapid increase in system complexity, with multiple RF sources, advanced pulsing and fine-tuned dM substrate temperature control now the norm in most plasma systems used for microelectronics fabrication. [2-4] Modeling and simulation has been critical not only in containing the escalating costs associated with development of such complex plasma processing systems but has also enabled shorter development time-scales. Plasma modeling is now widely used in the semiconductor equipment industry for exploratory research studies, system design, and hardware pte optimization. Plasma modeling is also indispensable for understanding the plasma behavior in the operating regimes of interest to help ensure one meets the stringent process requirements for today’s microelectronics fabrication. This paper illustrates some of the current uses of plasma ce modeling in the semiconductor industry using results from 3-dimensional (3D) hybrid and fluid modeling. Such plasma modeling is done hand-in-hand with feature scale modeling, flow and thermal modeling, kinetic plasma modeling, and 2D plasma modeling of processing chemistries to develop and optimize specific aspects of a given plasma processing system. [2-6] Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 3 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 pt The current multi-dimensional plasma models suitable for design and development of industrial plasma systems would not have been possible without the tremendous contributions by us cri the world-wide plasma community over the last 40 years. Many aspect of this research such as the development of computational algorithms and techniques, plasma diagnostics and fundamental atomic and molecular physics studies are indispensable for development of credible plasma models. Space limitations preclude us from highlighting all the important work in relevant areas. We mention only a few 3D plasma modeling studies here to partially illustrate their development timeline. Kushner et al. [7] described a 3D plasma model for an inductively an coupled plasma (ICP) etching reactor with planar coils. They used this model to examine the consequences of coil design and chamber asymmetries on plasma uniformity. Kushner [8] dM further expanded on this study and investigated the effect of asymmetric pumping on uniformity of charged and neutral species. Panagopoulos et al. [9] discussed 3D modeling of an ICP reactor and reported on the role a focus ring can play in alleviating azimuthal non-uniformities. Kenney et al. [10] developed a 3D model of parallel plate capacitively coupled plasmas (CCP). They investigated the effect of asymmetric metal and dielectric components as well as access ports on pte plasma uniformity. Chen et al. [11] investigated plasma spatial properties in a large area CCP using a 3D electromagnetic plasma model. The inclusion of the full set of Maxwell’s equations aided in demonstrating that higher order modes at very high frequencies (VHF) can lead to non- ce uniform plasma. Rauf et al. [12] used a 3D model of magnetized CCPs to study the role that different drifts play in determining the spatial characteristics of both electronegative and electropositive plasmas. For processing applications, it is imperative to have uniform plasma over the substrate. Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 Page 4 of 44 While general plasma characteristics can often be adequately investigated using 1 and 2- 4 Page 5 of 44 pt dimensional models, 3D models become useful for evaluating uniformity of complicated plasma sources. Most examples in this article focus on plasma uniformity. 3D modeling studies are us cri used to describe several source of plasma non-uniformity including plasma transport, electromagnetic wave propagation and magnetic field. A few strategies for improving plasma uniformity are also discussed. A few of our examples, such as the self-consistent electromagnetic modeling of inductive plasmas, introduce modeling innovations. Other examples add to the rather meager literature on 3D modeling of low temperature semiconductor- an processing plasmas. Experimental validation is an important aspect of model development. We have not addressed experimental validation in this article due to space limitations. However, our previous dM publications discuss validation of the underlying models for capacitively coupled [5, 13], electron beam based [14] and inductively coupled [15] plasmas. This article is organized in the following manner. The computational plasma models are described in Sec. 2. These models are used to study several plasma processing systems in Sec. 3. pte A brief summary is included in Sec. 4. 2. Multi-dimensional Plasma Models ce The computational plasma models used in this article have been described previously in the literature [10-14, 16], although these models have undergone significant changes since these publications. We briefly describe these models in this section and explain any new features used in the studies in Sec. 3. Two plasma modeling codes have been used in these studies. The first, Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 CRTRS, is a 1/2/3-dimensional hybrid plasma model. [12] Briefly, this model includes the 5 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 pt Poisson’s equation, continuity equations for all charged and neutral species, drift-diffusion approximation for electron flux, momentum conservation equation for positive ions, and the us cri electron energy conservation equation. Neutral species and ions are assumed to have a fixed temperature. Electrons can be treated as a fluid or a Monte Carlo model can be used in situations where kinetic effects are important. Kinetic treatment of electrons is found to be important at low pressures where non-local effects could be significant [13] and is necessary where beam-like energetic electrons are present. [14] CRTRS has the capability to model charged species transport in magnetic fields [12] and includes electromagnetic modules for simulating an inductively coupled and other high density plasma sources. During the computation, at every time step, the coupled set of Poisson equation, continuity equations for charged species and the dM ion momentum equations are first solved implicitly. This is followed by implicit solution of the electron energy conservation equation and explicit solution of neutral continuity equations. The second 2/3D plasma model, Mira, [16] is functionally similar to CRTRS but replaces the Poisson’s equation with the full set of Maxwell equations. While electrons can be treated as pte a fluid or kinetically using a Monte Carlo model in Mira, similar to CRTRS, results discussed in this work utilizing Mira treat the electrons as a fluid. The Maxwell equations have been discretized using the well-known Yee algorithm. [17] In Mira, one can solve the coupled set of Maxwell equations and charged species continuity equations either explicitly or implicitly in ce time. The electron energy conservation equation is solved implicitly and the neutral continuity equation is solved explicitly. Three-dimensional model investigations are computational expensive and time to results Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 Page 6 of 44 is critical to enable efficient design iterations and exploration of process regimes. To overcome 6 Page 7 of 44 pt these limitations, both CRTRS and Mira have been parallelized using MPI and results discussed herein were all run on Applied Materials’ supercomputing cluster utilizing at least 8 threads. us cri All simulations in this article are for Ar plasma. The Ar plasma chemical mechanism has been described earlier. [18] This mechanism includes electron, Ar+ ion, Ar* metastable and ground-state Ar. The same mechanism is used for both the fluid and the Monte Carlo models. 3. 3D Plasma Modeling Studies an a. Rectangular Inductively Coupled Plasma for Ion Implantation ICPs are an attractive source of ions for ion implantation [19 - 22] since they allow generation of large volume high density plasma, which can be used for extracting high current dM ion beams. A typical ion implanter consists of a plasma chamber with an extraction slit, set of ion beam extraction optics and a beamline to deliver the ion beam with desired specifications to the substrate. [21] The capability to reliably simulate plasma dynamics in the plasma source is critical to the design of the next generation ion implantation tools. In this paper we discuss pte successful development of such a high-fidelity simulation capability using CRTRS. The developed simulation tool addresses the two major sets of relevant plasma parameters: 1) plasma density, potential, composition to obtain detailed properties of the extracted ion beam (current, angular distribution, ionic composition, time-evolving properties, etc.) and 2) uniformity of the ce extracted ion beam. While the first set of plasma parameters, defining the ion beam properties, may be addressed by relatively fast 2D simulations, the uniformity studies and the ability to enable full scale modeling-based tool design necessitate 3D simulations. Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 A typical ICP source used in ion implantation tools is shown in Fig. 1. It consists of a rectangular plasma chamber with gas feed and a long slit to enable ion beam extraction. A 7 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 pt mixture of different gases (depending on the desired plasma composition) is fed into the chamber at a few mTorr gas pressure. Plasma inside the source is generated by a multi-turn RF antenna. us cri A dummy substrate, biased negatively relative to the source, is placed next to the chamber slit to extract an ion beam and analyze its properties. For the ion extraction system, conventional drift diffusion approximation for ions fails since inertia effects become important. For example, the direction of the ion beam is important. In the drift diffusion approximation, the extracted ion beam will always follow the direction of the electric field lines due to strong electric field in the extraction region. The ion trajectory could however deviate from the electric field lines due to an ion inertia. We are therefore using the full momentum equation for ions helping us to obtain reliable data for the extracted ion beam at the substrate. The use of semi-implicit algorithms dM allows using rather coarse grid (larger than Debye length) in the plasma generation region. However, the grid may be optionally refined in the ion beam extraction region if it is necessary to obtain detailed properties of the ion beam. We next present 3D simulation results for the rectangular ICP source with an extraction slit. The ICP source is 1 m long (in the direction of the slit), 0.5 m tall and 0.3 m wide. The extraction pte slit length is 0.5 m. The plasma chamber is filled with argon gas at various pressures (1, 2 and 4 mTorr). Argon plasma chemistry includes argon neutrals, excited species, ions and electrons. The plasma is generated using 1 kW, 2 MHz powered 5-turn RF antenna, wrapped around the ce source symmetrically with 5 cm spacing between the turns. In order to extract an ion beam, the substrate is biased using -1000 V DC voltage. Several cross-sections of Ar+ ion density distribution are shown in Fig. 1 inside the source at 2 mTorr gas pressure. The plasma density has a dumbbell-shaped distribution that gradually decays to the chamber walls. The plasma is Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 Page 8 of 44 strongest near the end of the coils (in the ±x direction) due to additional power coupling from the 8 Page 9 of 44 pt y-directed coil segments. The peak ion density is 2.6 × 1017 m-3. To analyze the extracted ion beam, the ion flux to the negatively biased “dummy” substrate is shown in Fig. 2. In this figure, us cri the color represents the ion flux, which has also been plotted along the z-axis. The extracted ion beam has a Gaussian-like shape with characteristic length and height close to the slit dimensions. The uniformity of the extracted beam also closely mimics the uniformity of the plasma inside the source, i.e. the dumbbell-shaped plasma distribution in the source is translated into dumbbellshaped extracted ribbon ion beam. The ion flux decreases rapidly in the y-direction around y = 0 due to narrow slit opening. an One of the important control knobs for ion beam uniformity is the gas pressure. The impact of pressure on plasma density profile is shown in Fig. 3 for pressures of 1, 2, and 4 mTorr. By dM increasing the gas pressure, the diffusion coefficient decreases leading to the plasma being more confined near the chamber walls, where it is primarily generated. If the gas pressure is decreased, the larger diffusion coefficient tends to move the plasma density peak to the center of the chamber. It is clear that with increasing pressure, the uniformity changes from center-peaked to edge-peaked. It is also worth mentioning that the peak plasma density increases with the gas pte pressure due to higher neutral Ar density and lower collision frequency. The change in uniformity in the source, from center-peaked at low pressures to edge-peaked at higher pressures, is also reflected in the ion beam flux extracted at the substrate, as shown in Fig. 4 where the ce normalized extracted ion flux is plotted at the center of the extraction slit (y = 0). b. Rectangular Capacitively Coupled Plasma Reactor Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 9 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 pt Plasma enhanced atomic layer deposition (PEALD) [23, 24] and plasma enhanced chemical vapor deposition (PECVD) [1] have been used in the semiconductor industry to deposit silicon us cri oxide, silicon nitride and carbon films. These films are deposited at moderately high pressure (0.1 - 20 Torr) to achieve good deposition rates while minimizing damage due to ion bombardment. In solar and display applications, large area PECVD chambers are often rectangular to accommodate rectangular processing substrates. These PECVD and PEALD plasmas sources have been extended to the VHF range in recent years. [25] This investigation focuses on plasma behavior in a rectangular parallel plate reactor operating an at 60 MHz. In this reactor, the plasma is formed in an 8 mm gap between the top powered electrode and the bottom electrode (where substrate is placed) as shown in Fig. 5. The RF feed dM to the powered electrode is located at the center of the reactor. The RF return path along the outer electrode is separated from the powered electrode by a 0.020 m wide dielectric (r = 9.0). The electrode is 0.34 m long and while the width of the electrode is varied between 0.06 and 0.34 m. The design symmetry in both x and y directions is leveraged to simulate only one quarter of the reactor geometry which also enables quicker design iterations. Characteristics in pte the rectangular CCP reactor have been investigated using Mira for a 6 Torr Ar plasma. The width of the electrode and power to the plasma are varied proportionately in order to maintain the same average power density in the plasma. For an electrode width of 0.06 m, the power to ce the plasma is 30 W while the power is increased to 170 W for 0.34 m wide electrode. Although we have kept the average plasma density constant, power deposition is not uniform. Our previous studies have shown that power has substantial impact on plasma and electromagnetic field uniformity [11]. Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 Page 10 of 44 10 Page 11 of 44 pt The vertical component of electric field below the powered electrode is shown in Fig. 6 for various electrode widths. For an electrode width of 0.06 m, the path length of electromagnetic us cri field in the transverse direction is substantially different from that in the longitudinal direction. The electromagnetic standing wave formed through reflections from the boundaries lead to a field distribution where the vertical electric field is weakest near the feed location, as shown in Fig. 6(a). The sheath electric field increases as we move away from the feed location. As the electrode width is increased, the electric field pattern changes with the lowest electric field location moving away from the feed location in the transverse direction, as shown in Fig. 6(b). an With further increase in electrode width, the location of peak sheath electric field gradually moves towards the center feed location as shown in Figs. 6(c-e). For example, an electrode width dM of 0.34 m results in the peak in electric field at the center feed location [Fig. 6(e)]. For this width, the path lengths in the longitudinal and transverse directions are the same leading to constructive interference at the center feed location. The electric field pattern changes with electrode dimensions primarily due to the interference of electromagnetic wave propagating in the different directions and its reflection from the reactor walls. In addition, the sheath electric pte field is enhanced near the edges due to material discontinuity, and this enhancement is especially pronounced at the corners. The sheath RF and DC electric field distributions determine power deposition to the electrons that determines the electron density distribution in the reactor. ce The electron density in the mid-longitudinal plane (y = 0) and the mid-transverse plane (x = 0) are shown in Fig. 7 for different electrode widths. In addition, electron density distribution in the x = 0.15 m plane is also plotted. For an electrode width of 0.06 m, electron density is lowest below the center feed location. Away from the center in the longitudinal plane, the electron Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 density gets enhanced due to stronger electromagnetic field coupling to the plasma. 11 The AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 pt enhancement in electron density is weaker in the transverse direction as the electric field is lower there. The electron density increases sharply near the edges of the electrodes where the electric us cri field becomes pronounced due to electrostatic edge effect. As the electrode width increases, the electron density becomes more uniform in both the longitudinal and transverse directions, as shown in Fig 7(b). For a width of 0.20 m [Fig. 7(c)], the electron density is high both near the center feed location due to electromagnetic effect and near the edges due to electrostatic effect. With further increase in electrode width, the peak electron density appears below the center feed location with decrease in electron density both in the longitudinal and transverse directions an before the electron density peaks again near the edge of the electrodes [Fig. 7(d-e)]. The electron density distribution closely mirrors the uniformity of sheath DC and RF electric fields due to the dM small gap and moderately high gas pressure. Ar+ is the only positive ion in the model so its density distribution is similar to the electron density distribution in the plasma due to quasi-neutrality. The ion flux distribution to the substrate (bottom electrode) is shown in Fig. 8 for different electrode widths, and it mimics the electron density uniformity trend. For the narrow electrode width of 0.06 m, the ion flux is pte lowest near the center feed location [Fig. 8(a)] and increases away from the feed location. With increases in electrode width, the ion flux to the substrate first becomes more uniform [Figs. 8(b) and 8(c)]. With a further increase in electrode width, the location of peak ion flux to the substrate ce shifts to the center [Fig. 8(d-e)]. In all cases, the ion flux is locally enhanced near the electrode edge. c. Cylindrical Capacitively Coupled Plasma Reactor Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 Page 12 of 44 12 Page 13 of 44 pt CCPs are widely used for plasma etching and deposition. A common design component in CCPs for plasma processing applications is a mesh or blocking plate and serves to confine the us cri plasma or act as an aperture to tune the relative amounts of species which may pass through. In the following, we consider the effectiveness of a grounded, perforated annular plate in confining a CCP to the process region above. This study has been done using CRTRS and electromagnetic effects have been neglected. In Fig. 9, the baseline chamber geometry is shown. The chamber inner diameter is 48 cm, an and it has a 5 cm electrode gap. A metal plate divides the chamber into upper and lower regions. The inner diameter of the plate is 32 cm, and it has a staggered array of 2 cm holes. There is 4 cm between the plate and the pump port. dM In Fig. 10, several electron density profiles are shown under varying conditions. For all simulations, an argon plasma at 20 mTorr is used, with 1000 W power applied from the bottom electrode. In Fig. 10(a), a frequency of 60 MHz is used to generate the plasma using the baseline chamber geometry. The plasma is largely produced near the electrode edge where the electric fields are largest, but the low pressure allows the plasma to diffuse throughout the chamber. The pte relatively high excitation frequency results in high plasma density, low voltages, and a thin sheath smaller than the holes in the metal plate. The plasma is able to pass through and obtain comparable densities above and below the plate, and the hole pattern shows up clearly as dimples ce in the highest density isosurface. In Fig. 10(b), the impact of reducing the excitation frequency to 15 MHz is shown. Under these conditions, the plasma density is reduced and requires voltage increase, resulting in a Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 thicker sheath than at 60 MHz. The plasma is still able to penetrate the mesh and obtain comparable densities above and below it, but now the importance of the local hole topology is 13 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 pt more pronounced. In regions where the staggered grid is relatively rich in holes, the plasma is able to pass through and maintain a high density. In other regions, the plasma is largely us cri suppressed below the grid. This gives much larger non-uniformities in plasma density below the grid, ultimately with an impact feeding back into the region above the grid. In Fig. 10(c), the impact of reducing the hole size is considered, here using the 15 MHz process. The holes in the metal plate are reduced to 1 cm in diameter, with a more dense but similarly staggered pattern. In this case, plasma is largely suppressed from entering the region an below the metal plate, and a significant disconnect is seen between the upper and lower plasma profiles. Here still, however, we see perturbation in the plasma density profile in the region dM above the plate, owing to interactions with the imperfect array of holes in the plate. d. Cylindrical Inductively Coupled Plasma Reactor ICP chambers are pervasive in the semiconductor industry and are extensively utilized for silicon and dielectric materials etching. The uniformity and yield requirements of plasma etching at advanced technological nodes (<10 nm) necessitate multidimensional antenna pte segments to ensure azimuthal uniformity. Other aspects of the ICP chamber such as systems for gas flow and temperature control are also often housed in the source region which can affect the electrical characteristics of the antenna. To investigate the effect of such design choices on the ce plasma characteristics and uniformity necessitates a 3-dimensional electromagnetic plasma model where the electromagnetics of the ICP antenna and the antenna-plasma coupling are treated self-consistently. [26] Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 Page 14 of 44 To illustrate this capability, the schematic view of an ICP chamber is shown in Fig. 11. The antenna structure comprises of a 30 cm diameter, 4-turn segmented coil fed coaxially at the 14 Page 15 of 44 pt center. An azimuthally-segmented Faraday shield sits atop the 4 cm thick alumina-like dielectric window (εr = 9.0) to minimize capacitive fields. The 30 cm diameter wafer is surrounded by us cri alumina and sits 15 cm below the dielectric window. The coils are terminated to ground using posts which connect the coils to the chamber wall at a radius of 30 cm. Two design variants of the ICP antenna structure are investigated in this work. The posts from the coil to the ground can overlap with either the dielectric window, as shown in Fig. 11(a) or with the Faraday shield, as shown in Fig. 11(b). Plasma characteristics for these design variants are investigated in a 250 W, 30 mTorr discharge sustained in Ar. The voltage at the coaxial feed is adjusted to deliver a total an power of 250 W at 13.56 MHz. Note that the power so defined does not distinguish between inductive or capacitive. The computational mesh is approximately 48×48×80 points in the x, y, dM and z directions respectively. These simulations have been done using Mira. The magnitudes of inductively coupled and axial electric fields in a plane 1 cm below the window are shown in Fig. 12 for the two design configurations. The corresponding electron power deposition due to these fields, also in a plane 1 cm below the window, is shown in Fig. 13. The peak inductively coupled electric field is 253.6 V/m and is azimuthally asymmetric due to pte the finite number of coil segments (4) and their ground return legs. The peak in the inductively coupled electric field, in Fig. 12(a), occurs where the ground termination of the coils overlaps with the dielectric window, while the location, in Fig. 12(b), coincides with midway between the ce ground termination locations. The peak in inductive power deposition (22.5 × 103 W/m3) coincides with the peak in electric field and is similar between the two design variants, concomitant with the similarity in magnitude of the inductive electric field. The peak axial electric field is 787.4 V/m and is dominant near the edge of the metal-dielectric boundary Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 corresponding to the Faraday shield and at the larger radii near the chamber wall. The peak in 15 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 pt capacitive power deposition (2.0 × 103 W/cm3) is an order of magnitude lower than that coupled inductively. The axial electric field in the plasma is shielded by an order of magnitude due to the us cri Faraday shield. This effectiveness is also confirmed by lower capacitive power deposition relative to inductive despite the larger magnitude of the axial electric fields. The axial electric fields in the plasma are lower where the coil terminations overlap with the Faraday shield (peak of 510 V/m). This decrease is driven in part by the fact that the coil termination to ground serves as a pseudo Faraday shield and so inhibits the fields somewhat an above the dielectric window. Another reason for this decrease (and variation in peak location) is driven by the transmission line characteristics of the coil and plasma as the antenna structure design utilizes a coil whose length is less than ¼ of the wavelength of the driving frequency. For dM the design variant in Fig. 11(b), the termination overlap with the Faraday shield results in a larger termination capacitance and so the impedance increases. This larger impedance increases the current along the coil and so results in peak in the fields midway through the coil termination. The larger impedance to ground is also confirmed by the voltage at the co-axial feed. For the design variant shown in Fig. 11(a), 1049.7 V is required to couple 250 W while 1104.3 V is pte required for the variant shown in Fig. 11(b). The net inductive power deposition in the plasma volume is estimated to be 222.4 W vs 232.6 W between the two designs. Radial slices of the electron density are shown in Fig. 14 for varying distances from the ce dielectric window of 2, 4, and 6 cm. The peak electron density is 2.7 × 1017 m-3 and the finite coil segments result in the azimuthal profile mirroring the structure also seen in the inductive fields and power deposition. While the large distance between the dielectric window and the Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 Page 16 of 44 wafer typically helps to smear out this azimuthal profile, the large operating pressure of 30 mTorr limits the diffusion transport and so the center of the chamber does not fill well even near 16 Page 17 of 44 pt the mid-gap (at 7.5 cm, not shown). This is also confirmed, in part, by the fact that the location of the peak in electron density at any axial location does not vary significantly. The large us cri electron density limits the penetration of inductive electric field deep into the plasma region and so the density near the wafer is limited by diffusion. Even as the density is low, smearing of the azimuthal asymmetry at least occurs at locations closer to the wafer. The electron density shown in Fig. 14(b) corresponds to the design variant when the coils termination overlaps with the Faraday shield and is uniform relative to the profiles in Fig. 14(a) when the coils termination overlaps with the dielectric window. The peak location and azimuthal profile of the electron an density is driven by the peak in ionization rates coinciding with the peak in the inductive electric fields and low competing losses either by diffusion or recombination as might occur in dM electronegative gases. The uniformity improvement for the schematic in Fig. 11(b) when the termination capacitance is large has also been reported by Kushner et al. [7] This work illustrates that antenna generated asymmetries can be introduced by design choices as simple as coil termination above the Faraday shield versus dielectric window. The antenna generated azimuthal asymmetries in plasma production can persist over large lengths (such as the pte wafer plane) and place added importance on proper coil design. While the electrical characteristics of ICPs can be characterized using a circuit model, a 3-dimensional model is necessary to evaluate the impact on plasma uniformity over a range of plasma conditions and ce chamber designs. e. Electron Beam Generated Magnetized Plasma Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 With the critical microelectronics device dimensions shrinking below 5 nm, thin film processing is increasingly requiring atomic level precision. [27] Ion energy is one of the key 17 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 pt attributes that influences device fidelity during plasma processing. [28] There has been significant interest in lowering the ion energy in plasma systems to alleviate ion induced damage us cri and improve fabrication precision. One method to reduce ion energy is to use low electron temperature (Te) plasma generated using an energetic electron beam. [29-31] The energetic electron beam necessitates kinetic treatment of electrons using a Monte Carlo model in CRTRS, which has been described in Ref. [14]. This model is also validated against experimental probe measurements in Ref. [14]. The reactor geometry is shown in Fig. 15(a) and 15(b). The electron beam source (shown in green) is 2.5 cm tall and 41 cm wide. The energetic electrons an are launched from the surface facing the vacuum chamber. All surfaces are considered to be electrically grounded. The top surface is 2.25 cm away from the center of the beam (z = 0.05 m) dM while the bottom surface is 1.75 cm away. A magnetic field is used to confine the electron beam and the bulk plasma. This magnetic field is generated using the set of circular coils shown in Fig. 15(b). For the results reported here, the coils are arranged in the Helmholtz configuration with D = 2W = 0.8 m. The coil currents are similar and they have been adjusted to obtain 120 G magnetic field at (x,y,z) = (0,0,0.05) m. The magnetic field at the center of the beam (z = 0.05 m pte plane) is shown in Fig. 15(c). This magnetic field is predominantly in the x-direction and uniform in the plasma region except for slight curvature near the sidewalls in the y-directions. The electron density for Ar plasma at 20 mTorr gas pressure, 0.98 A/m2 beam electron ce current density, and 1.5 keV beam electron energy is shown in Fig. 16. The density has been plotted in the z = 0.05 m and x = 0.06 m planes. A moderate density plasma is produced under these conditions. As shown in Fig. 10(c) in Ref. [14] for identical conditions, peak Te ≈ 1.25 eV. The electron density, ne, exhibits non-uniformities in all directions, which require a closer Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 Page 18 of 44 examination. First, ne increases as one moves away from the electron beam source in the +x- 18 Page 19 of 44 pt direction. This non-uniformity is linked to the cross-section for Ar ionization, which decreases with energy for electron energies greater than a few hundred eV [32]. As the beam electrons collisions. us cri move away from the beam source, they lose some energy through elastic and in-elastic The less energetic beam electrons farther away from the source have higher ionization probability, which results in ne increasing with x. Despite the chamber geometry and magnetic field being symmetric around the y = 0 plane, ne is larger in the y > 0 region. This nonuniformity is due to the E×B drift. Sheath electric field is directed away from the plasma at all surfaces. With B predominantly being in the x-direction, the plasma is expected to drift in the +y an direction above the beam center (i.e., z ≥ 0.05 m) and –y direction below it. This reactor is slightly asymmetric in the z-direction with more volume above the beam center compared to dM below it. Consequently, more of the charged particles experience the +y drift and we see a higher plasma density in the y > 0 region. One can observe in Fig. 16(b) that the plasma is stronger above the center of the beam (shown as dashed line) than below it. This non-uniformity is linked to the bottom electrode being closer to the beam than the top electrode. This disparity results in more plasma loss at the bottom electrode and weaker plasma below the beam center. pte To verify the above conclusions regarding non-uniformity in the y and z directions, the beam center is shifted to the top half of the chamber. The resulting reactor geometry is similar to that in Fig. 15(a), but with the beam source moved up by 5 mm. In this configuration, the top surface ce is 1.75 cm from the center of the beam (z = 0.055 m) while the bottom surface is 2.25 cm away. Electron density for this simulation is shown in Fig. 17. The peak in ne moves to the y < 0 region [Fig. 17 (a)] if the plasma volume is smaller above the beam than below it because more of the plasma is now experiencing E×B drift in the –y direction. In addition, as shown in Fig. 17(b), Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 the plasma is stronger below the beam center due to the smaller distance between the beam and 19 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 geometry on plasma pt the top electrode. These results illustrate the significant influence of us cri uniformity in magnetized plasmas. 4. Conclusions Plasma chambers that enable thin film processing in the semiconductor industry operate over a wide range of pressures and have to meet the stringent process requirements desired of a typical high volume manufacturing industry. To meet these stringent requirements, plasma Plasma an processing systems have greatly increased in system complexity in recent years. modeling plays an important role in their design to enable shorter development time-scales. A number of 3-dimensional (3D) fluid and hybrid plasma modeling examples were used to dM illustrate the applications of plasma modeling in plasma hardware design in this article. We first described a 3D fluid model for a rectangular ICP source, used for extracting ions for ion implantation. It was shown that gas pressure strongly influences the ion flux uniformity, which is determined by the balance between where the plasma is produced and how much it spreads pte through diffusion. The effects of chamber dimensions on plasma uniformity in a narrow-gap rectangular CCP, used for deposition, were examined using a fully electromagnetic plasma model. Due to high pressure and small gap in this system, plasma uniformity was found to be primarily determined by the electric field profile in the sheath / pre-sheath region. The ce confinement properties of a mesh in a cylindrical CCP, used for etching and deposition on Si wafers, were investigated over a range of excitation frequencies. Results highlighted the role of hole topology and size on the formation of localized hot-spots. Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 Page 20 of 44 We also computationally investigated a cylindrical ICP where both the RF sections in the source and the plasma were simulated using a fully electromagnetic plasma model. This model was used to study inductive 20 Page 21 of 44 pt vs. capacitive power coupling and how placement of ground return wires relative to the Faraday shield influences this power coupling. Finally, a 3D hybrid plasma model for an electron beam us cri generated magnetized plasma was used to understand the role of reactor geometry on plasma uniformity in the presence of E×B drift. In the foreseeable future, we expect plasma modeling to remain a major tool for the design and development of plasma processing systems for microelectronics fabrication. These models considerably shrink the development time and reduce the number of expensive iterations one has an to go through to design a successful product. Plasma models are increasingly being expected not just to answer fundamental design questions but to help optimize the design details such as dimensions and shapes. Hence, 3D plasma models have increasingly become important for the dM design of industrial plasma processing equipment. Given the computational expense of 3D plasma modeling, it remains a challenge how to incorporate most relevant physics in them (e.g., non-local transport, plasma chemistry), resolve important details (e.g., sheaths), and still be able ce pte to do the simulations in a reasonable time. Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 21 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 pt References 1. Doering R and Nishi Y, editors 2008 Handbook of Semiconductor Manufacturing us cri Technology, 2nd Edition, CRC Press, Boca Raton, FL 2. Zhang Y, Zafar A, Coumou D J, Shannon S C and Kushner M J 2015 J. Appl. Phys. 117, 233302 3. Banna S, Agarwal A, Cunge G, Darnon M, Pargon E and Joubert O 2012 J. Vac. Sci. Technol. A 30, 040801 an 4. Agarwal A, Rauf S, and Collins K 2012 J. Appl. Phys. 112 033303 5. Agarwal A, Dorf L, Rauf S, and Collins K 2012 J. Vac. Sci. Technol. A 30 021303 6. Rauf S, Dorf L, Kenney J A, and Collins K 2013 J. Appl. Phys. 113 023306 dM 7. Kushner M J, Collison W Z, Grapperhaus M J, Holland J P, and Barnes M S 1996 J. Appl. Phys. 80, 1337 - 44 8. Kushner M J 1997 J. Appl. Phys. 82 5312 - 20 9. Panagopoulos T, Kim D, Midha V, and Economou DJ 2002 J. Appl. Phys. 91, 2687 96 pte 10. Kenney J, Rauf S and Collins K 2009 J. Appl. Phys. 106, 103302 11. Chen Z, Rauf S and Collins K 2010 J. Appl. Phys. 108, 073301 12. Rauf S, Kenney J, and Collins K 2009 J. Appl. Phys. 105, 103301 ce 13. Rauf S and Balakrishna A 2017 J. Vacuum Sci. Technol. A 35, 021308 14. Rauf S, Balakrishna A, Agarwal A, Dorf L, Collins K, Boris D R and Walton S G 2017 Plasma Sources Sci. Technol. 26, 065006 15. Agarwal A, Foucher M, Rauf S, Booth J.-P., Chabert P, and Collins K, AVS Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 Page 22 of 44 International Symposium, Oct. 18 – 23, 2015, San Jose, CA. 22 Page 23 of 44 17. Yee K S 1966 IEEE Trans. Antennas Propagat. 14, 302-307 us cri 18. Rauf S and Kushner M J 1997 J. Appl. Phys. 82 2805 - 2813 pt 16. Rauf S, Chen Z, and Collins K 2010 J. Appl. Phys. 107, 093302 19. Brown I G 2004 The Physics and Technology of Ion Sources, 2nd Revised and Extended Edition. 20. Agarwal A and Kushner M J 2007 J. Appl. Phys. 101 063305 21. Ito H 2016 Proceedings of 2016 21st International Conference on Ion Implantation Technology, 26-30 September 2016, Tainan, Taiwan. an 22. http://www.appliedmaterials.com/products/varian-viista-trident 23. Dingemans G, van Helvoirt C A A, Pierreux D, Keuning W, and Kessels W M M dM 2012 J. Electrochemical Soc. 159, H277 - H285 24. Ovanesyan R A, Hausmann D M, and Agarwal S 2015 ACS Appl. Mater. Interfaces 7, 10806−10813 25. Chen H, Tu Y, Hsieh C, Lin D and Leou K 2014 J. Appl. Phys. 116 103307 26. Agarwal A, Kenney J A, Rauf S, and Collins K 2014 Trans. Plasma Sci. 42 2832 pte 27. Dorf L, Wang J C, Rauf S, Monroy G A, Zhang Y, Agarwal A, Kenney J, Ramaswamy K, and Collins K 2017 J. Phys. D: Appl. Phys. (accepted for publication) ce 28. Agarwal A and Kushner M J 2009 J. Vacuum Sci. Technol. A 27 37 29. Walton S G, Boris D R, Hernández S C, Lock E H, Petrova T B, Petrov G M and Fernsler R F 2015 ECS J. Solid State Sci. Technol. 4, N5033–40 30. Lock E H, Fernsler R F and Walton S G 2008 Plasma Sources Sci. Technol. 17 Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 025009 23 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 pt 31. Boris D R, Petrov G M, Lock E H, Petrova T B, Fernsler R F and Walton S G 2013 Plasma Sources Sci. Technol. 22 065004 ce pte dM an us cri 32. Rapp D and Englander-Golden P 1965 J. Chem. Phys. 43, 1464–79 Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 Page 24 of 44 24 Page 25 of 44 pt Figure Captions 1. Ar+ ion density distributions inside the rectangular ICP plasma source operating at 2 us cri mTorr pressure. (a) xz cross-section and (b) yz cross-sections. 2. 2D distribution of the extracted Ar+ ion flux to the substrate in the rectangular ICP plasma source operating at 2 mTorr pressure. 3. Ar+ ion density distribution inside the rectangular ICP plasma source operating at (a) 1 mTorr, (b) 2 mTorr and (c) 4 mTorr pressure. an 4. Extracted ion beam uniformity at the substrate in the rectangular ICP source at different pressures. 5. Computational geometry used for modeling the rectangular CCP reactor dM 6. Time-averaged vertical component of electric field Ez below the powered electrode for different electrode widths in the rectangular CCP. These simulations have been done at 6 Torr gas pressure in Ar, and the RF power is scaled with the electrode width. 7. Electron density as a function of electrode width in the rectangular CCP at 6 Torr gas pressure in Ar. RF power has been scaled with the electrode width. Each plot includes pte electron density in the y = 0, x = 0, and x = 0.15 m planes. 8. Electron density in the mid-plane between the top and bottom electrodes in the rectangular CCP. These simulations have been done at 6 Torr gas pressure in Ar, and the ce RF power is scaled with the electrode width. 9. Schematic of baseline cylindrical CCP chamber geometry with 2 cm diameter holes in the mesh. 10. Electron density isosurfaces with (a) baseline geometry and 60 MHz excitation Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 frequency, (b) baseline geometry and 15 MHz excitation frequency, and (c) reduced hole 25 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 at 20 mTorr and 1000 W RF power. Note: log scale. pt size (1 cm diameter) and 15 MHz excitation frequency. All simulations are for Ar plasma us cri 11. Schematic view of the ICP chamber with multi-segmented coil fed through the co-axial feed. Design variants when the coils termination overlaps with (a) dielectric window and (b) Faraday shield. 12. Radial slices of the magnitude of inductive (top) and axial electric fields (bottom) in the 250 W, 30 mTorr Ar ICP plasma taken 1 cm below the dielectric window. Design variants when the coils termination overlaps with (a) dielectric window and (b) Faraday an shield. The contours are on a linear scale. 13. Radial slices of the inductive (top) and capacitive power deposition (bottom) in the 250 dM W, 30 mTorr Ar ICP plasma taken 1 cm below the dielectric window. Design variants when the coils termination overlaps with (a) dielectric window and (b) Faraday shield. The contours are on a linear scale. 14. Radial slices of the electron density in the 250 W, 30 mTorr Ar ICP plasma taken 2, 4, and 6 cm below the dielectric window. Design variants when the coils termination pte overlaps with (a) dielectric window and (b) Faraday shield. The contours are on a linear scale. 15. (a) One half of the plasma reactor geometry. (b) Top-down cross-section of the plasma ce reactor at z = 0.05 m. (c) Static magnetic field in the z = 0.05 m plane. This magnetic field has been generated for D = 2 W = 0.8 m. Magnetic field at (0, 0, 0.05) m is 120 G. 16. Electron density in the (a) z = 0.05 m and (b) x = 0.06 m planes. These results are for Ar plasma at 20 mTorr gas pressure, 0.98 A/m2 electron beam current density, and 1.5 keV Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 Page 26 of 44 26 Page 27 of 44 pt beam electron energy. Center of the beam source at z = 0.05 m has been indicated using a dashed line. us cri 17. Electron density in the (a) z = 0.055 m and (b) x = 0.06 m planes. These results are for Ar plasma at 20 mTorr gas pressure, 0.98 A/m2 electron beam current density, and 1.5 keV beam electron energy. The electron beam source has been raised by 5 mm relative to the geometry in Fig. 15(a). Center of the electron beam source at z = 0.055 m is ce pte dM an indicated by the dashed line. Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 27 (a) pt dM an us nAr+ (m-3) ce pte nAr+ (m-3) Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 Page 28 of 44 cri AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 (b) Figure 1 of 17 Agarwal et al. pt cri an us dM pte Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 ce Page 29 of 44 Figure 2 of 17 Agarwal et al. an us cri nAr+ (m-3) (a) pte dM nAr+ (m-3) (b) nAr+ (m-3) ce Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 Page 30 of 44 pt AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 (c) Figure 3 of 17 Agarwal et al. pt cri an us dM pte Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 ce Page 31 of 44 Figure 4 of 17 Agarwal et al. pt an us Outer Dielectric Electrode Feed Plasma Feed dM Powered Electrode 2 0 0 5 10 0 pte Z (cm) Bottom Electrode (Substrate) 2 4 6 15 20 ce Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 Page 32 of 44 cri AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 Figure 5 of 17 Agarwal et al. 32 0 28 an us 5 (b) Width 0.13 m, power 65 W 0 5 10 dM (c) Width 0.20 m, power 100 W 0 5 10 pte (d) Width 0.27 m, power 135 W 0 pt (a) Width 0.06 m, power 30 W ce 5 10 15 (e) Width 0.34 m, power 170 W Z (cm) Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 AUTHORElectric SUBMITTED MANUSCRIPT Vertical Field Ez [kV/m] - JPhysD-113397.R1 cri Page 33 of 44 2 0 0 0 5 5 10 10 15 15 20 20 Figure 6 of 17 Agarwal et al. ne [1016 m-3] (a) Width 0.06 m, power 30 W 13 an us 26 (d) Width 0.27 m, power 135 W 0 5 dM (b) Width 0.13 m, power 65 W 0 5 0 5 pte 10 10 15 (e) Width 0.34 m, power 170 W 0 5 10 2 Z (cm) ce (c) Width 0.20 m, power 100 W Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 cri Print on Full Page Width Page 34 of 44 pt AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 1 0 0 0 5 5 10 10 15 15 20 20 Figure 7 of 17 Agarwal et al. Ion Flux [m-2.s-1] 5 1.61019 (a) Width 0.06 m, power 30 W 0 Y (cm) (b) Width 0.13 m, power 65 W 5 0 (c) Width 0.20 m, power 100 W 5 dM Y (cm) 10 an us Y (cm) 1.01019 0 (d) Width 0.27 m, power 135 W 5 pte Y (cm) 10 0 (e) Width 0.34 m, power 170 W ce 15 10 Ac Y (cm) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 pt AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 cri Page 35 of 44 5 0 0 5 10 X (cm) 15 Figure 8 of 17 Agarwal et al. pt an us dM pte ce Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 Page 36 of 44 cri AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 Figure 9 of 17 Agarwal et al. pt an us dM (a) ce pte (b) (c) Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 cri Page 37 of 44 Figure 10 of 17 Agarwal et al. pt an us dM pte ce Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 Page 38 of 44 cri AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 Figure 11 of 17 Agarwal et al. pt cri an us dM pte Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 ce Page 39 of 44 Figure 12 of 17 Agarwal et al. pt an us dM pte ce Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 Page 40 of 44 cri AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 Figure 13 of 17 Agarwal et al. pt cri an us dM pte Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 ce Page 41 of 44 Figure 14 of 17 Agarwal et al. z 0.28 m y x an us (a) cri 0.10 m dM 0.0 ebeam Source Y (m) 0.3 -0.3 -0.3 pte (b) Beam Dump W 0.0 X (m) D 0.3 (a) D = 2W = 0.8m 0.3 |B| (G) 160 Y (m) ce Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 Beam Dump ebeam Source Page 42 of 44 pt AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 0.0 -0.3 -0.3 (c) 140 120 100 0.0 X (m) 0.3 Figure 15 of 17 Agarwal et al. -0.3 -0.3 (a) 0.0 X (m) 0.3 dM 0.10 cri 0.0 an us Y (m) 0.3 pt ne (Max. = 1.1×1016 m-3) Z (m) 0.08 0.06 0.04 pte 0.02 0.00 -0.3 (b) Min. Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 0.0 Y (m) 0.3 Max. ce Page 43 of 44 Figure 16 of 17 Agarwal et al. ne (Max. = 1.1×1016 m-3) -0.3 -0.3 (a) 0.0 X (m) 0.3 dM 0.10 cri 0.0 an us Y (m) 0.3 Z (m) 0.08 0.06 0.04 pte 0.02 0.00 -0.3 (b) 0.0 Y (m) 0.3 Max. ce Min. Ac 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 Page 44 of 44 pt AUTHOR SUBMITTED MANUSCRIPT - JPhysD-113397.R1 Figure 17 of 17 Agarwal et al.