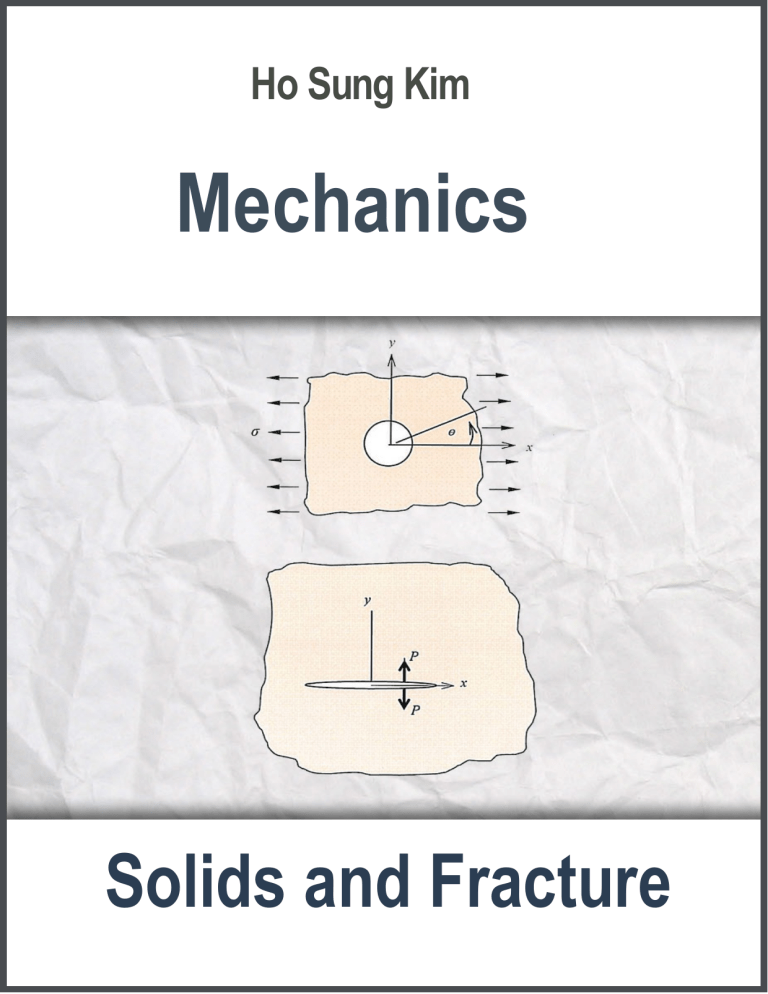

расчеты мех(by-Kim-H.S.)-Mechanics-of-Solids-and-Fracture-3067769-(z-lib.org)

advertisement