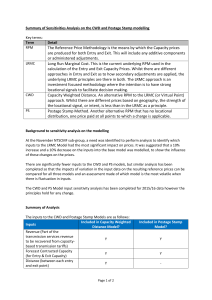

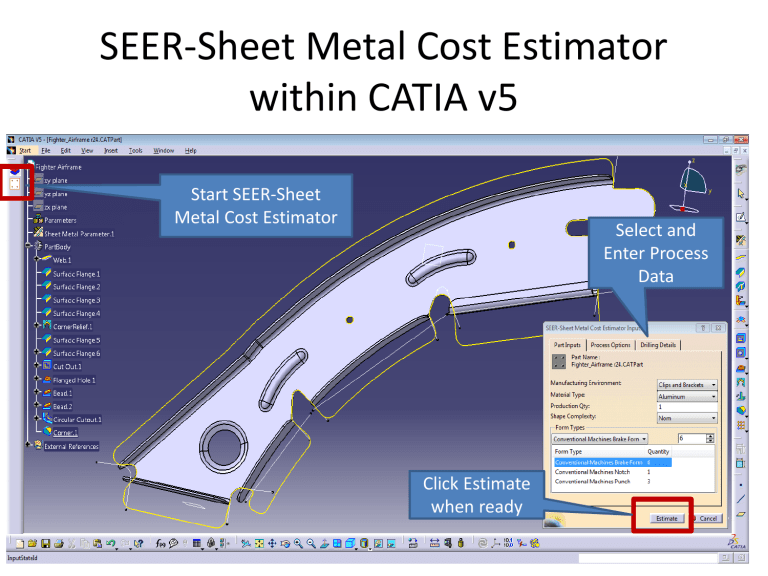

SEER-Sheet Metal Cost Estimator within CATIA v5 Start SEER-Sheet Metal Cost Estimator Select and Enter Process Data Click Estimate when ready SEER-Sheet Metal Cost Estimator Part & Process inputs • Customize Manufacturing Environments to set Part and Process Defaults • Hole part features are automatically added if separate drilling cost estimation required Manufacturing Environment Part Inputs Process Options Hole Drilling Options SEER-MFG Cost Model Cost Results Summary reported to CATIA Engineer Detailed SEER-MFG cost model created based on CATIA and Sheet Metal Cost Estimator Inputs Results Saved with CATIA Data saved as Parameters within CATIA for reference Cost Trend of Trade studies indicated Key Functionality • Create detailed sheet metal part cost estimates for labor (setup, direct, inspection, rework), material, and tooling costs. • Update and refresh estimates as the design matures. • Comprehensive part cost estimates covering all commonly used fabrication forming process, preforming, post forming, and finishing operations. • Create and save estimate for each part to compare and trade options. • Customizable knowledge base templates and rules to fit your factory environments, labor rates, and processes. • Publish estimates as SEER cost models to be shared with SEER users for inclusion into other estimates. • CATIA users can review the estimate, even if Sheet Metal Cost Estimator and/or SEER are not installed. Set CATIA Options to view SEER-Sheet Metal Cost Estimator Parameters • Tools > Options > General > Parameters and Measure > With Value = TRUE • Tools > Options > Part Infrastructure > Parameters = TRUE Create Manufacturing Environment 1a – Copy an Existing Environment folder 1c – Rename Environment 1b – Paste to create a copy Edit SEER Knowledge Bases 2a – Double Click to open SEER-SMCE-KBases.MFG file a) Double click the SEER-SMCE-KBases.mfg file to open it. b) Make edits to SEER inputs as required e.g. labor rates, labor calibration, production experience, etc. to match the environment. Save and Close SEER. 2b – Make Changes as required, Save, and Close Edit Manufacturing Environment a) Open the SEER-SMCE Template Editor.xlsm file within the manufacturing environment you want to update/edit. b) Make Changes to data as required in each table. c. Click Save Environment Settings, and then OK. This will save the SEERMFG KBases, and the spreadsheet data for the manufacturing environment. d. Save and Close the SEER-SMCE Template Editor.xlsm spreadsheet. Edit Environment Material Tables • • • Material Analogy Tables contain Form, Pre-Form, After Form, and Detailed Part Finish Operations, these can optionally be modified. Set Defaults to appear using Yes/No options. You can OPTIONALLY remove form operations (rows), or process specific operations (table columns) from the Material Analogy Tables To remove Form operations, delete the entire Row To remove a Process Option, delete column within the table